Hello everyone - a couple updates to the home built conveyor - getting to be more of a professional grade these days

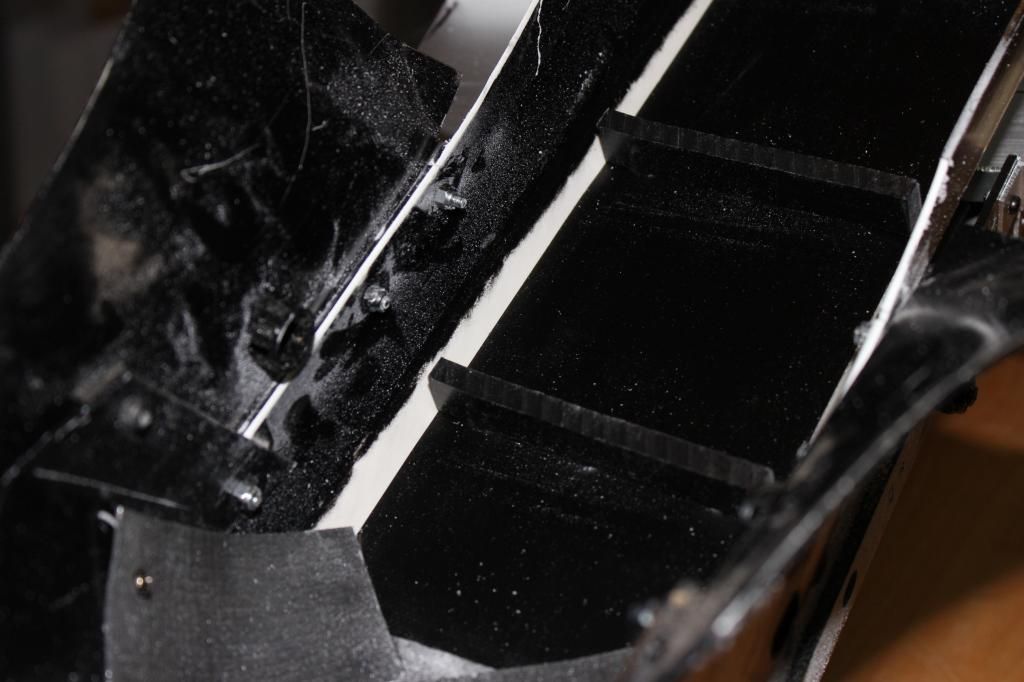

So after during the first year the main drive motor and pulley set up just couldn't handle the loads against it so I went down to the local Wal Mart and picked up a 1/2 drill and some electric cord. Removed the main drive pulley and mounted the drill with duct tape. Noisy as all get out but was effective. For year 2 I removed the drill and installed a screw drive 90degree angled drive unit (windshield wiper motor) from robot market place. And a 110 to 12V power convertor. Worked fantastic. So now after about 3 year of use the blue jean material "belt" has given up. I had to install some sand paper around the main drive hub in year one to get traction and well - it just simply ate the material up. Early last year I had picked up a used belt form a check out register stand (hard to find, but make friends wherever you can). Got lucky and the belt happened to be a good length. Cut it to width and mounted paddles with flat head screws.

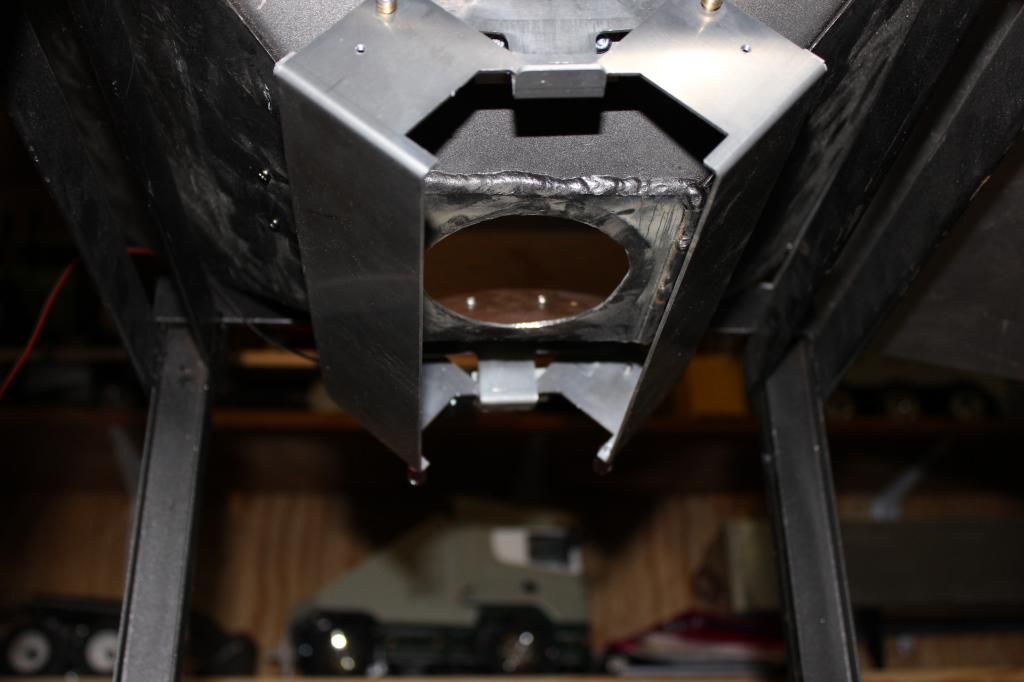

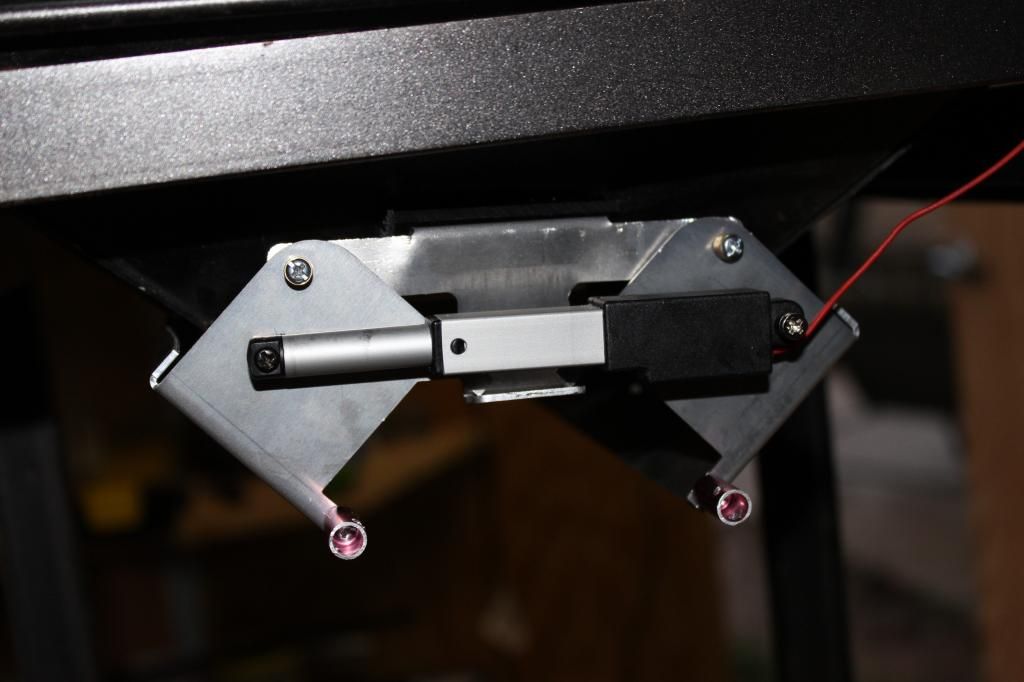

As for the Gravity box. Started out with a manual handle on a swash plate (think air damper on a grill). That worked OK but was a pain when the hopper was in the middle of the city layout at Indy. So for year 2 I installed a cable system and remote handle - used a bicycle brake cable sheath (purchased in bulk length from a local bike shop) and a good length of 1/8" aircraft cable (sturdy enough to push as well as pull). Big issue has always been the opening of the swash plate. Rubber would clog the opening and debris would collect and catch. So for this year I have installed a system off one of my bottom dump trailers using a firgelli. Opened up the swash plate and wow, we have a full 4" diameter opening to fill trucks. I don't see this clogging up anytime soon.

Other improvements are holes int eh upper support trough to let out any debris that finds its way under the belt before it gets tot he idler pulley. A bottom support to lift the feed end off the floor and keep the paddles from binding on the under trough. And adjusting the upper trough to be just under the belt and supporting it (limiting the gap under the belt to keep debris out.

We still have the over flow chute added for Year #2 - this is so that after so much the conveyor can stay running and the overflow exits the box and doesn't compromise the conveyor.

Some pics