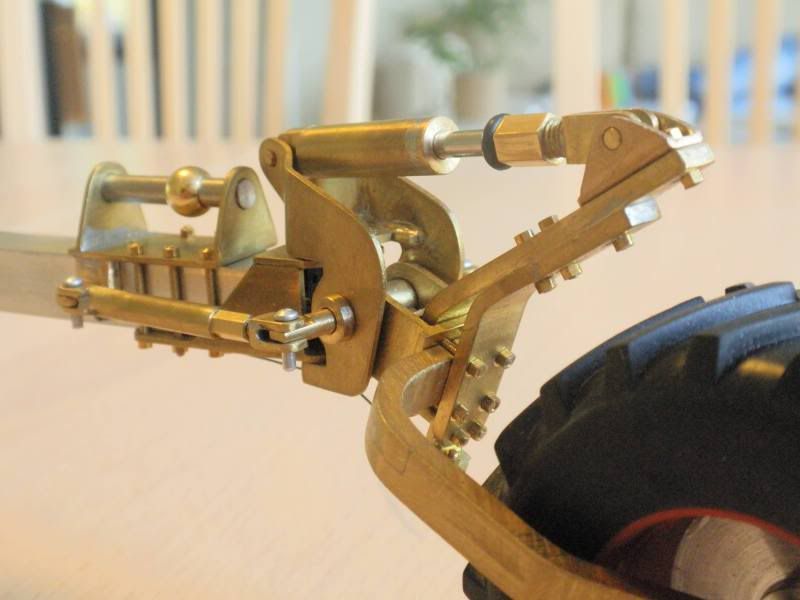

Headstock

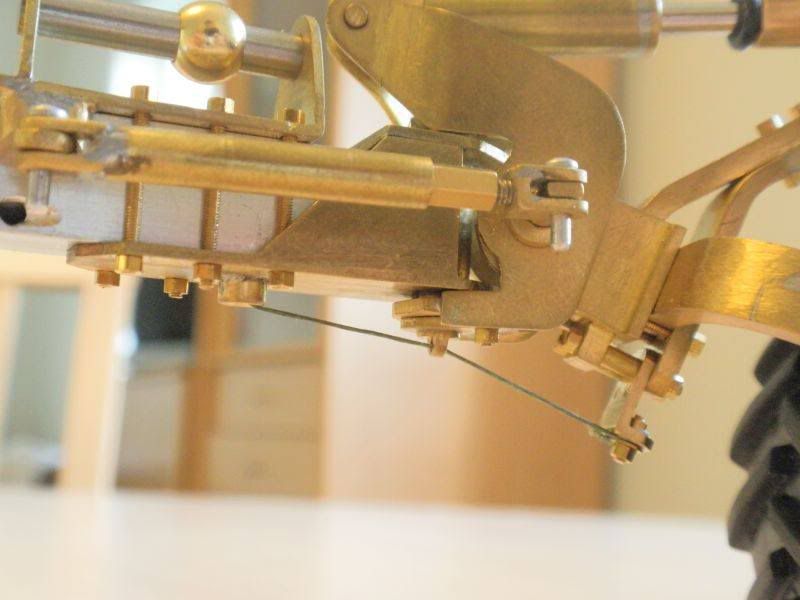

Turning part. Also take a look at the small tools. It’s actually real tools made for the small nuts.

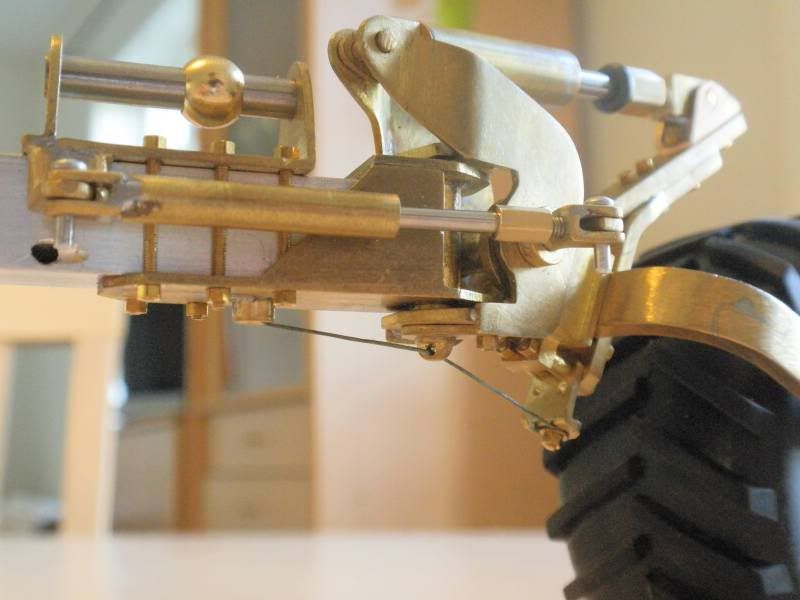

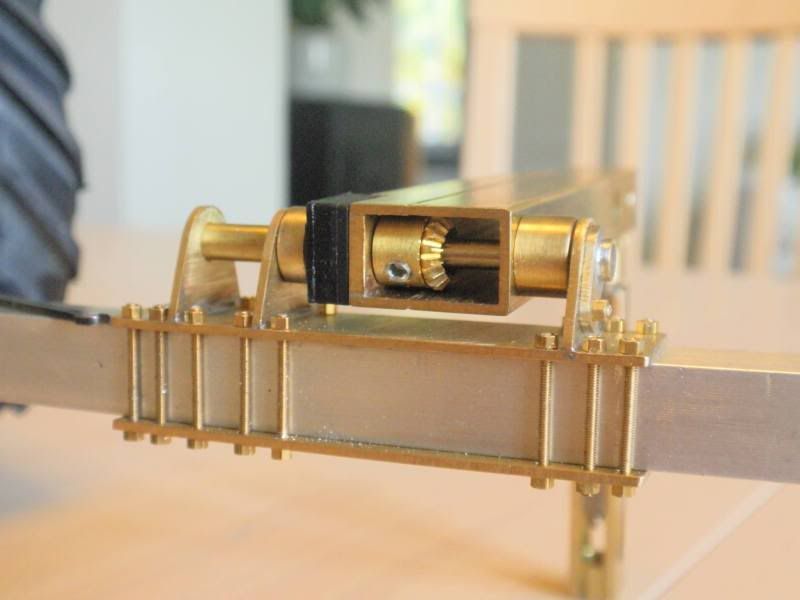

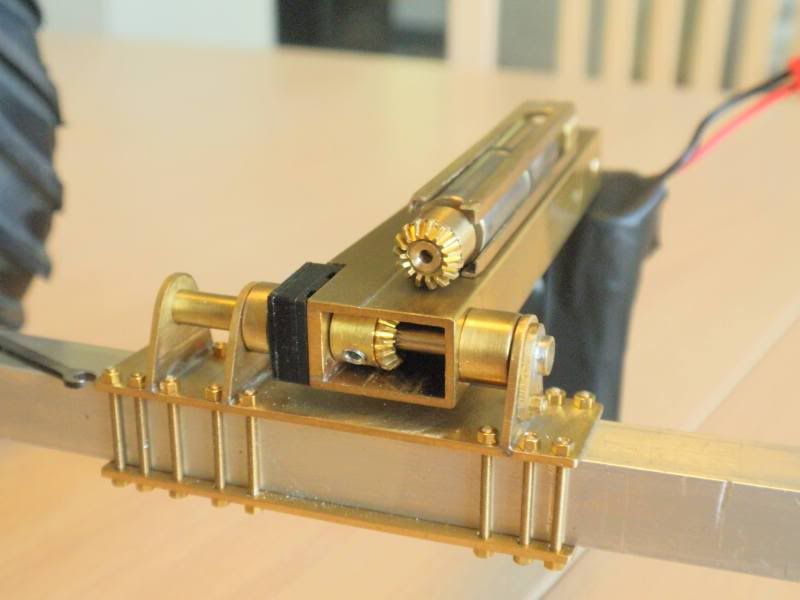

In these two following pictures you will see the secrets of the turning part.

Two 90dgr. bewelgears and a motor do the trick. A potentiometer is mounted to set the endpoints and it can be fine tuned via the radio controller.

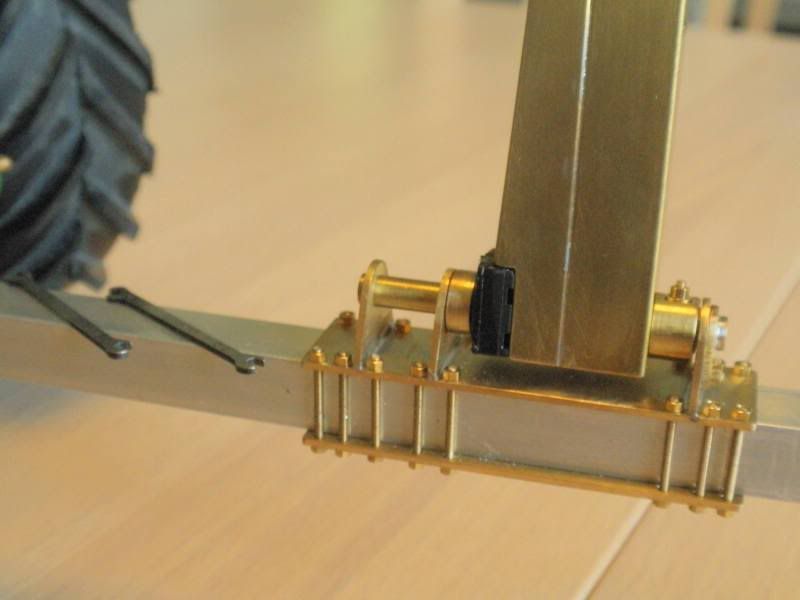

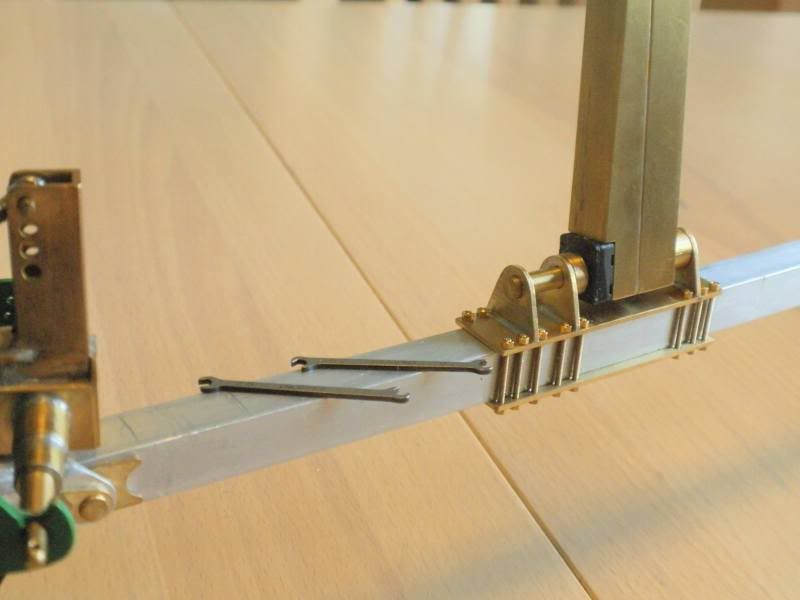

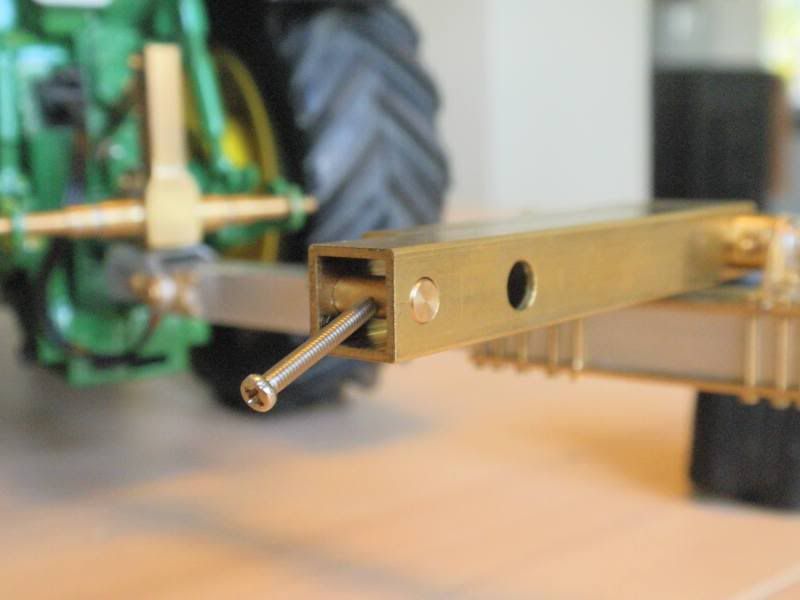

Here is the start of the first furrow adjustment. It will be adjusted via a spindle…

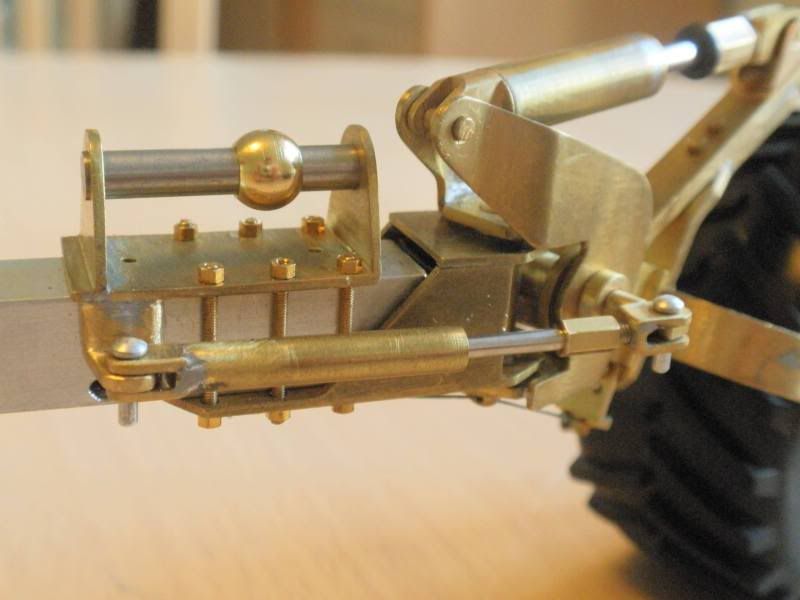

Rearend is done, except of the fender over the cylinder. Turning cylinders are done with adjustment-nuts

When you take a look under the plowframe you will notice the wire coming out to raise and lower the plow. Fine tuning is done by the nut on the cylinder