Quote:

Originally Posted by tc1cat

Very nice start on a great project! If you want to go even smaller than the 0-80 machine screws you might want to try www.scalehardware.com He has nuts and bolts down to .5mm. He also has taps for that size. I have only had the nerve to try 1 hole in .5mm. Came out OK but very nerve racking as it was the final detail on the part. |

Hi Lynn. Thanks for checking out my work. Yes, I've looked at Scale Hardware's website a few times. Like you, I'm a little nervous about tapping something smaller then an 0-80 thread! I've done a lot of 2mm threaded holes now, but that's .078" diameter, roughly. 0-80 is smaller yet, at about .050". But .5mm at .0196"? Yikes! I'd be really worried about snapping the tap, if I just looked at it wrong. Though 0-80 screws are still a little large for what I want to do, I think I can accept that, since the idea of breaking off a tap, and ruining a part that I have a lot of time stuck into machining, is a poor trade off! Guess we'll see. I should have the 0-80 screws and taps I ordered, tomorrow.

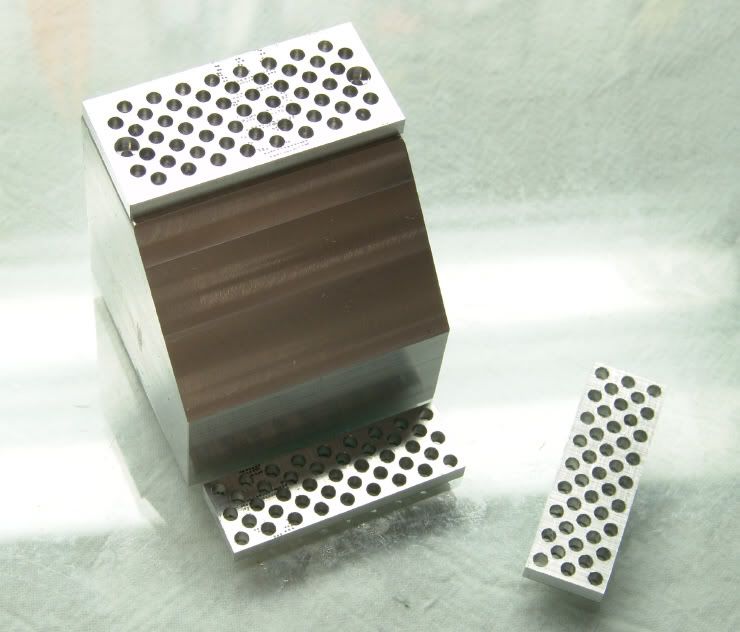

Forging ahead! I got two more tread plates for the steps done this morning.

Here's another photo, that shows how I hope to tie the steps to the boxes. I've got some step side members machined, that will pretty much bolt together, like the 1:1 steps will. These are not finished parts yet. The front edge (lip) will be milled off completely, at an angle, to match the 1:1 steps. In the next stage of machining, they'll be finished. Sometimes you have plan how you are going to hold onto such small parts, for each step of the machining process. They are oversized right now, but will get trimmed down to size soon enough. The top step will be slightly narrower then the bottom step and the side members will be angled to meet the top step. One just has to look at the 1:1 prototype photo I posted to see what I mean.