I need some help here. When I open page 6 of this thread, I am logged in. When I go to page 7, I am NOT logged in, and may not post replies. And, try as I might, I can not log in. I definitely know my password and forum name. I am replying from page 6 as I write. Ideas?

Edited in: now on p 7, since I replied from page 6, I'm logged in. Odd.

Anyway, thank you, Rob. I have to tell you I am anything but a veteran when it comes to RC. This crane is my only venture into RC, and I only RC'ed it cuz it was the only way to make it functional at any level. I'm mainly a 1/25 scale model truck builder. (and switch off occasionally to HO model RR, simple DC only) And when you look at the caliber of machinery being engineered and built on this forum, you'll see I'm kind of a runt here. That said, I'd be glad to help any way I can.

As mentioned above, The crane is undergoing a heavy makeover to downsize it Here's a before picture. Note the extended front end, the size of the wheels, and how high the carrier deck is, compared to that little figure by the rear wheel.

Now note all the above on this take.

While I don't follow any one specific 1/1 prototype crane for this build, I do try to stay within "typical" parameters. I do lean heavily on Link Belt and P&H influence. Call it "protolanced", to borrow a model railroader term.

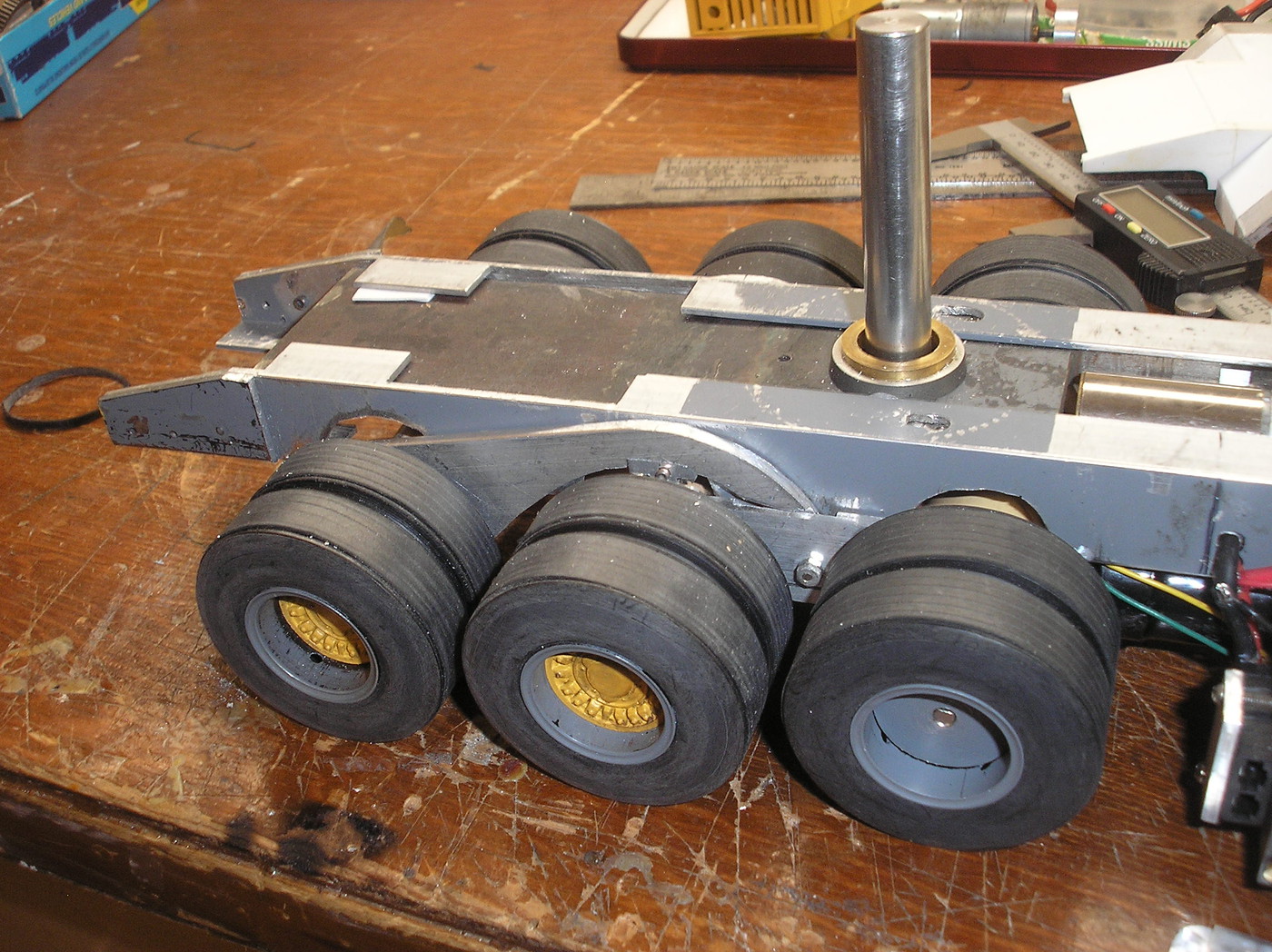

The overall length of the carrier was shortened around 9 scale feet, (over 4"), the deck height lowered about 14 scale inches, and the width of both the carrier and the upper unit were narrowed about 10 scale inches. This brings it well into scale proportions compared to a Link Belt HC 278 H, the class of cranes I'm shooting for.

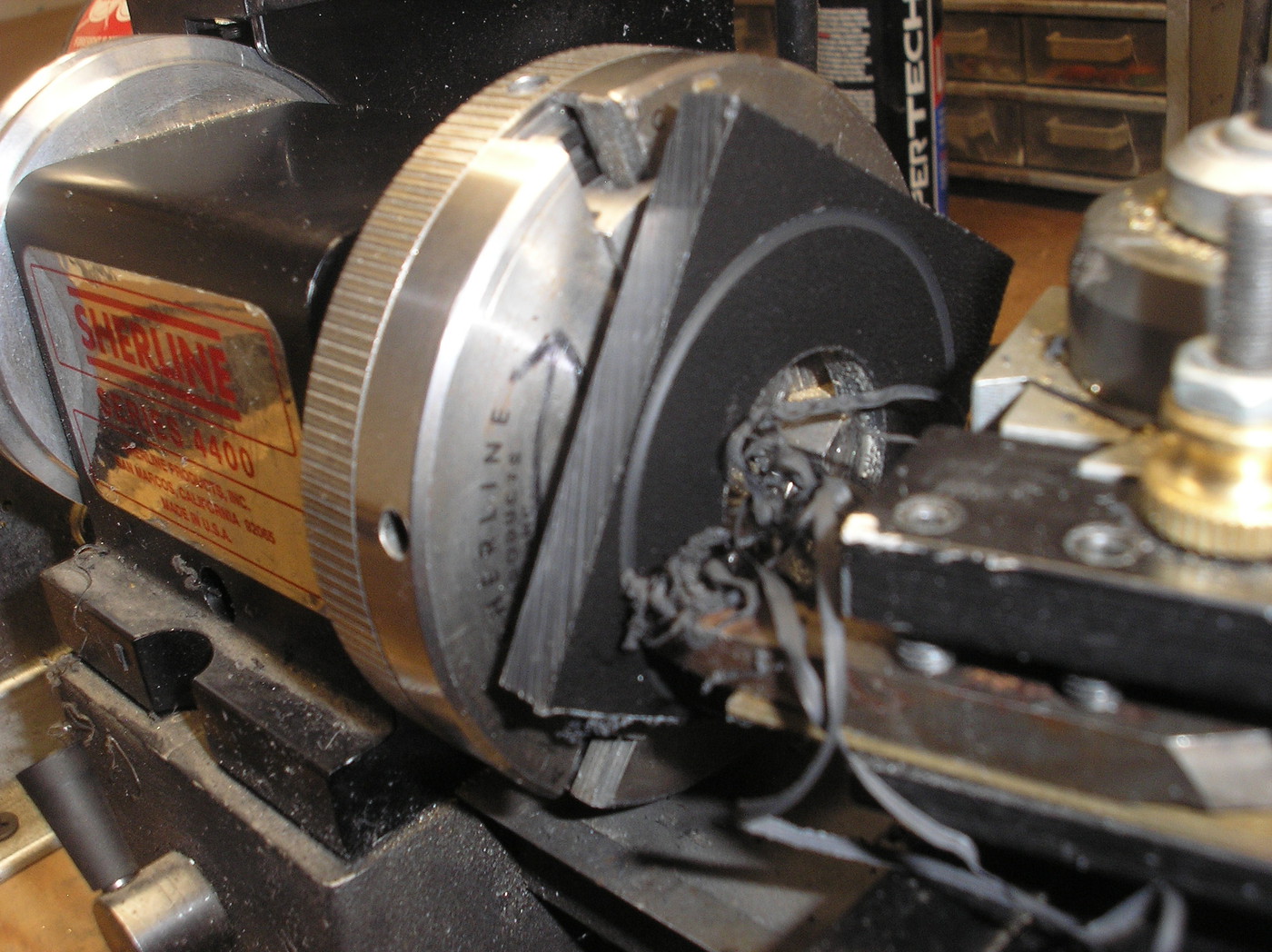

Original tires were pirated from (gulp) 3 Ertl AMT Payhauler 350 dump trucks. They'll be returned now. New smaller tires were scratchbuilt from black ABS pipe connectors and 1/4" ABS sheet, for the sidewalls. VERY messy lathe work. The treads are made from bands of bicycle inner tube for traction and quiet operation on a hard floor.

Once the sidewalls were glued in with pipe cement, They were sanded which left them a lighter flat black color, and I left them at that.

Note also in that last picture the new narrower rear equalizing suspension pieces, the access notches cut into the frame to allow wheel/axle travel, and how deep the hub detail is inset into the rim due to narrower motor-gearheads. All hard earned lowering, narrowing, and length shortening processes.

I'll post before I lose this again.