|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

|

Thread Tools | Display Modes |

|

#1

|

|||

|

|||

|

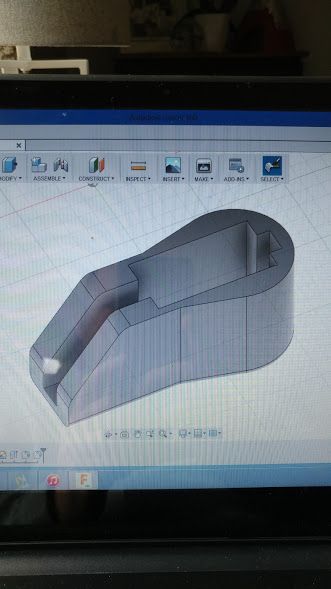

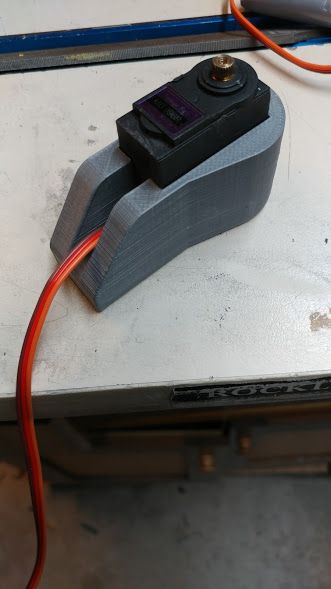

After recently completing my little bruder bulldozer conversion I decided to next have a try at making an excavator. I began with a Bruder 320 and began cutting plastic. I will post pictures below as I make progress. I am teaching myself how to 3d model using Fusion 360 (free) and then printing the parts on my 3d printer. I will be using modified servo motors for the tracks as well as for slewing. I ordered a magom hydraulic pump and I am going to attempt to make my own cylinders and valves when I get that far.

Mount for track motor.   Hub Adapter  All Glued together

|

|

#2

|

|||

|

|||

|

Painted

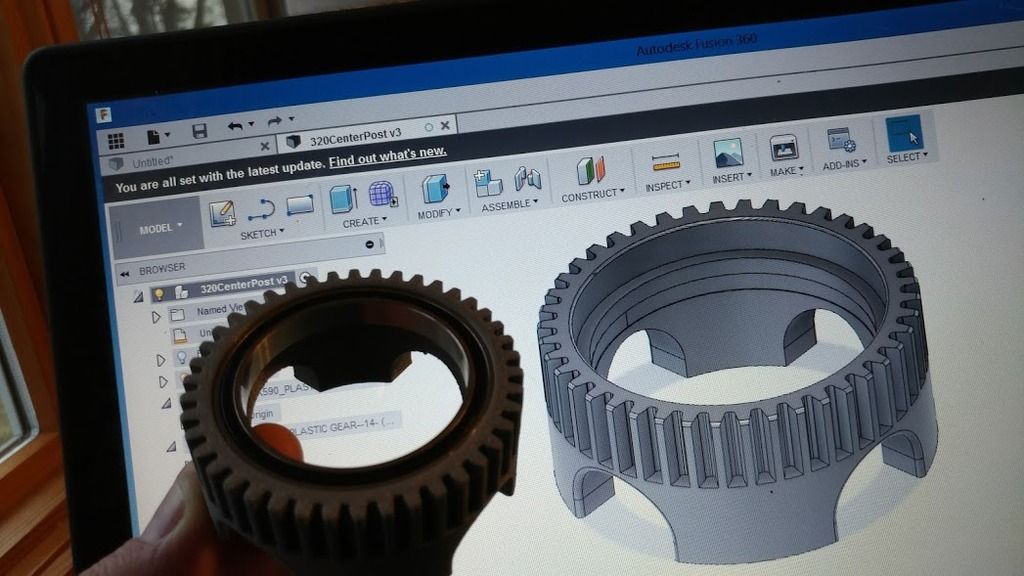

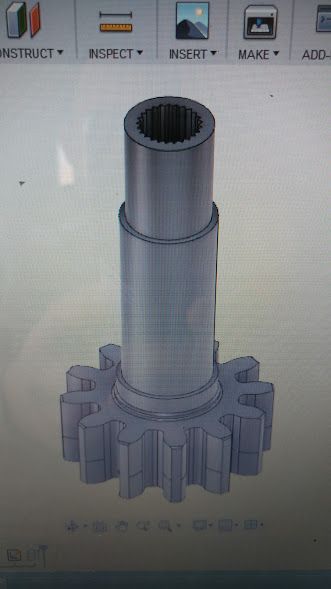

Center pivot and gear.   Top Pivot  Assembled   Pinion gear

|

|

#3

|

|||

|

|||

|

Bearing Holder

There is as slip ring in there but I forgot to take pictures of it.

|

|

#4

|

||||

|

||||

|

Wow, that is slickon owl-stuff!

__________________

Giving up is not an option!!! Rob |

|

#5

|

|||

|

|||

|

nice build ! you have good idea for that build ! keep up good work !

|

|

#6

|

|||

|

|||

|

wow thats amazing work . i cant wait to see it all complete .

you might have to print me those files... my printer is down at this time |

|

#7

|

|||

|

|||

|

Thanks for the kind comments, it is coming together ok as time allows. My pump and valve body arrived from Magom in Spain yesterday, what little pieces of art those are. I am currently working on attempting to build my own cylinders that hopefully wont spew oil all over the place

|

|

#8

|

|||

|

|||

|

Nice work! I love that turn table with a bearing and everything. Now time to try some 3d printed hydraulic cylinders?

|

|

#9

|

|||

|

|||

|

The cylinders are proving to be difficult to construct. There is a fine balance between too tight/won't move, and too loose/leak all over. Unfortunately though the printer is of no help there since the parts need to be machined and very smooth, and to pretty accurate size. I will post a pic if I can get a cylinder working later.

|

|

#10

|

|||

|

|||

|

yeah I would imagine you would have to machine everything just like you would with metal. I would think doing a acetone smoothing that would create almost a hardened shell around the outside of a abs part and then machine that. Everytime I try to get a good finish on this thermoplastic it ends up melting and I havent been able to get a real good surface finish, but I havent invested too much time trying either.

|

|

#11

|

|||

|

|||

|

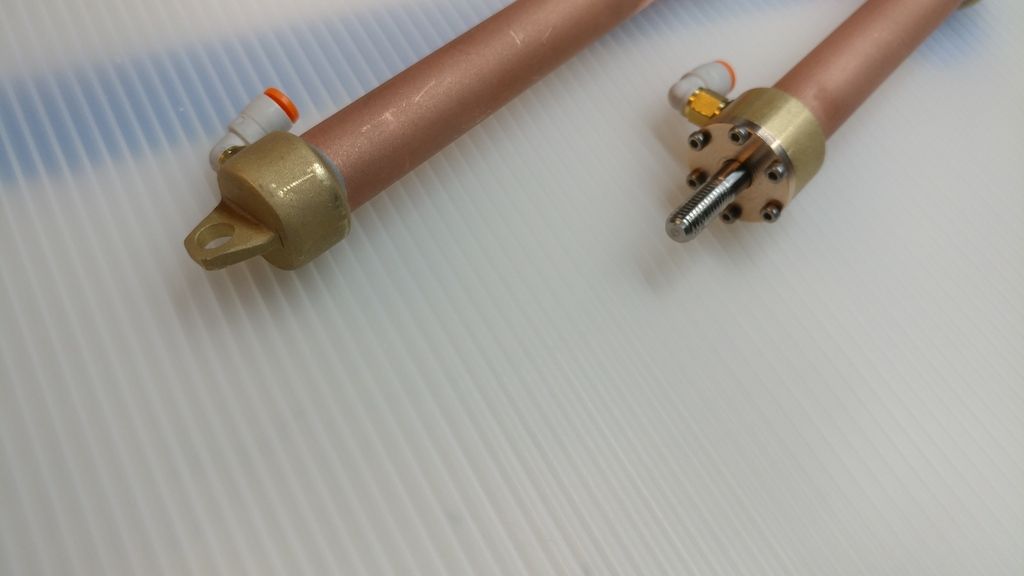

Here are some pics of a couple of the cylinders I made. 1 of the three I made is perfectly leak free, the other two ....not so much! Nothing horrible but they are dripping around the gland where the shaft leaves the end of the cylinder. It looks like I need to re invent my seals somehow. It was pretty neat to see them moving though, and even with the pump just barely turning they are quite powerful.

|

|

#12

|

|||

|

|||

|

Very nice work on the 3D printed parts and custom cylinders.

|

|

#13

|

||||

|

||||

|

Wow those cylinders look absolutely superb.

Please could you publish drawings/details of them? Have you used lost wax castings for some of the parts? I would like to be machining these out of barstock 5 Last edited by 5inchman; 02-27-2017 at 04:15 AM. |

|

#14

|

|||

|

|||

|

Thanks for the compliments. The cylinders are simple in theory but I am finding that having the gland end seal without leaks is easier said than done. I made 4 cylinders. 2 are great while the other 2 leak so my design of using o rings as a seal may not prove to be workable in the end. No casting is involved, all lathe work. the barrels are just 1/2" copper pipe which happens to already pretty much have a mirror finish inside (I assume from the drawing process) and the end caps are machined from brass stock. the internals of the cylinders consist of aluminum pistons with steel shafts. No drawings, but if you look on the MagomHRC website you will see that they have very good exploded drawings. Honestly for about 50 bucks a cylinder it is probably best to just buy the cylinders from them, but where is the fun in that!

|

|

#15

|

|||

|

|||

|

You are doing some nice work here. Guess you are finding the cylinders a bit tricky to make. Keep at it- you can make it work. Good Luck

|

|

#16

|

|||

|

|||

|

If you are going with Magom cylinders this french forum has a guy who modified his Magom cylinders to be more reliable as far as leaks.

http://camions-rc.fr/forum/viewtopic...4474&start=240 He might also have more information on what he did in this build thread, I'm not really sure where. http://camions-rc.fr/forum/viewtopic...2937&start=360 I use Google translate to read his stuff.

__________________

Youtube username iamaman27 |

|

#17

|

||||

|

||||

|

Quote:

|

|

#18

|

|||

|

|||

|

It has proven to be a bit more difficult than I thought it would be to eliminate the leaks around the shaft of the cylinder. I haven't done anything with them for a couple weeks but I will get back to them soon, in the meantime I will follow the links posted above to see what I can learn. Thanks!

|

|

#19

|

|||

|

|||

|

Quote:

|

|

#20

|

|||

|

|||

|

Me likes it a LOT

|

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|