|

|

|||||||

| Construction Equipment Tech Hydraulics, Electronics, General Engineering, ect in constr equip |

|

|

|

Thread Tools | Display Modes |

|

#1

|

||||

|

||||

|

I recently purchased a new leimbach pump and this pump does not have a motor yet ..I want to install a brushless motor ..I was looking at the upgrade for them at leimbachs website and with so many available from tower I thought I may save a few bucks by buying here in north america..Tower has a very wide selection

Question is which one is comparable ? This is the specs leimbach has for their brushless ..I am not quite sure what the shaft size is •Operating voltage: 12V or 7, 2V •Speed: 0 to approx. 12000 RPM •Receiver power supply: 5V Max 3A |

|

#2

|

|||

|

|||

|

Do you have the motor mount, and dog drive from Leimbach? Even for a brushed one, that way you can measure off those. I am not sure what the spec are... Hopefully someone has one that isn't installed yet.

Cheers, AP |

|

#3

|

||||

|

||||

|

Is there and advantage to using brushless motors in our hobby. I thought stock high turn motors have more torque and are better battery life with the new brushless motors.?

|

|

#4

|

||||

|

||||

|

I've had two different brushless motors on a Leimbach pump. Initially I used This discontinued motor which spun pretty quick, but has a standard 1/8" shaft and mounting holes like any other 540/550 motor (25mm I think). All I had to do was cut the shaft shorter.

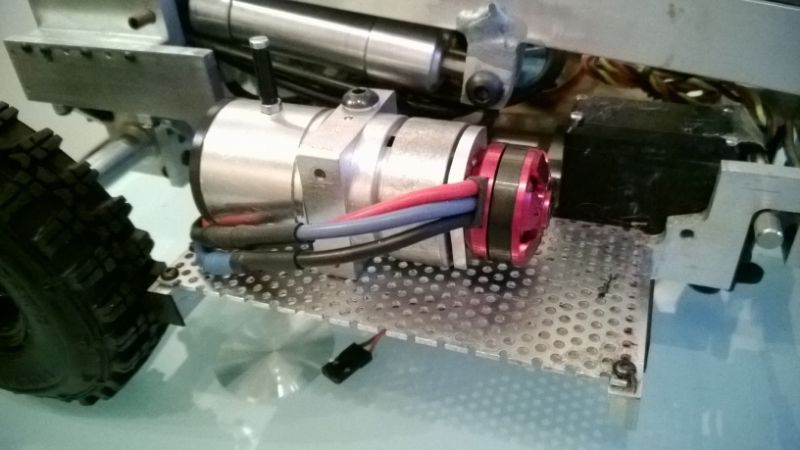

That was overkill so I tried out a tiny outrunner which I got from china. It needed an adapter plate to mount it and I a machined a new coupler to work with this motors smaller shaft (2mm). It has no problem running the cylinders. I looked at the motor's Kv (which is rpm per volt applied) while considering my battery of choice. If the mounting holes and shaft size match you'll be good to go. If you want to match the max rpm of the leimbach system (12000rpm) you'll need a motor with around 1000Kv for 3s lipo, or 1600Kv with a 2s lipo.  Don't mind the sideways pump, my lines are all tangled so I couldn't reinstall it rightside up. Lmackattach: I began looking at brushless only to decrease the footprint of the pump. |

|

#5

|

||||

|

||||

|

Thanks AP ..Yes I do have the mount and dog drive ..its a little differend couple system then my older pumps ..this one doesnt have the rubber coupler in between the two but looks as it will work fine ...the shaft size is .125 or 3.175 mm so that should help when picking one out ..Wonder if the motor mounting holes are all pretty standard as well

Lmackattack I think why Leimbach offers it is that it supplies a higher speed and a bit more flow for the upgrade ..on their page its recommends not to run it at full speed for long periods .. For some reason i had though it help with longer run times as well but may be wrong Blender .Thanks ..that looks pretty slick very small footprint indeed ..Thanks for the tip on KV ..starting to understand a bit more now .. Last edited by tracksntreadslou; 10-19-2013 at 06:12 PM. |

|

#6

|

||||

|

||||

|

heres the upgrade Leimbach offers

http://www.microsofttranslator.com/B...lessmotor.html |

|

#7

|

||||

|

||||

|

Brushless motors are more efficient then brushed motors, with similar performance specs. I use the term 'similar' lightly because it is almost impossible to do a direct comparison between the two motors. They are so different in construction, and in the way they operate. One of the biggest things that make brushless motors more efficient is the simple fact that they do not rely on brushes to energize the armature poles, or windings. Brushes produce drag (rotational friction) on the motor's commutator and waste energy. Brushes wear with time, reducing efficiency. Spring tension on a motor brush grows weaker as the brush wears also. A brushless motor's only rotational friction comes from the shaft bearings, and brushless motors do not loose efficiency with time, as long as they are run within rated current and voltage specs. Heat is just about the only enemy, as it is for any motor. Brushless outrunner motors also produce much more torque by design. The motor can has multiple magnets inside of it, and most outrunner motors have more poles then a brushed motor. Most brushed motors have 3 or 4 poles. An outrunner usually has somewhere between 6 to 16!

To say run time is longer with a brushless motor vs. a brushed motor could be true, but in theory a brushless motor can have a short run time as well. It just depends what you demand of it. The important thing to remember is the amount of work that the motor can do. With a brushless motor being more efficient at converting electricity into torque, there is less wasted energy, hence more work being done.

__________________

Nathan |

|

#8

|

||||

|

||||

|

Thanks Nathan ..and Everyone else for the input ..this is going to help very much when i pick out a motor for the pump..Every Day I learn something new on here ..Glad to be part of a great forum

|

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|