|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

|

Thread Tools | Display Modes |

|

|

|

#1

|

|||

|

|||

|

Quote:

Quote:

Yes i dont like the Vario sidewalks either, thats why i made my own, turned out better i think. No they dont make any metal tracks yet, but when or if they do i will get them! Quote:

Yeah, its close enough! Sadly we have a thing called winter and that sucks, but it gives a lot of time of building parts, modding, i mostly dont clean it, its just my hands when i work on it thats does the cleaning!  But if its very dirty after a run i usually just take the tracks off and clean them out then its good. But if its very dirty after a run i usually just take the tracks off and clean them out then its good. I like also like a clean machine, at least on top and under the body, but the undercarrige im not to clean about when its season!  And i also have a cover for it when im not working on it or using it becuse i have it in my workshop and it gets quite wet and dirty at times. And i also have a cover for it when im not working on it or using it becuse i have it in my workshop and it gets quite wet and dirty at times.

|

|

#2

|

||||

|

||||

|

So any modified parts that you make, just make 2 so I can purchase them from you. I am serious. So let me know if you you ever have extra.

Thanks, Eddie |

|

#3

|

|||

|

|||

|

Quote:

I finally got the new tripple grousers on, the package got lost in transit and was delayed by about a week, now it has the right shoes for the model it is. The snow has finally started to melt over here and its not much left, maybe still frozen in the ground but its on the way to get diggable!

|

|

#4

|

|||

|

|||

|

Finally got some time to run the hitachi, have worked a lot this summer in another city, today a guy on a Swedish forum called me and wanted to meet so we did, it was a great day in the sun.

He had his Stahl 742 dozer and a deere tractor with dump bed, very nice models. I have also got new brushless motors for the track drive that I'm going to mount as soon as I get home, also a new version of the grading bucket is taking shape. Other then that I'm going to try to save up to a THS Volvo L250G!  Here is a few pics from today...   [IMG]http://i172.photobucket.com/albums/w20/gcrawler/201 31013_163426_zps0ba592a8.jpg[/IMG]

Last edited by Azonic; 10-13-2013 at 12:31 PM. |

|

#5

|

|||

|

|||

|

|

|

#6

|

|||

|

|||

|

Nicest vario I've seen!

|

|

#7

|

||||

|

||||

|

Beautiful machine, would be nice to have a realistic looking operator in the seat.

|

|

#8

|

||||

|

||||

|

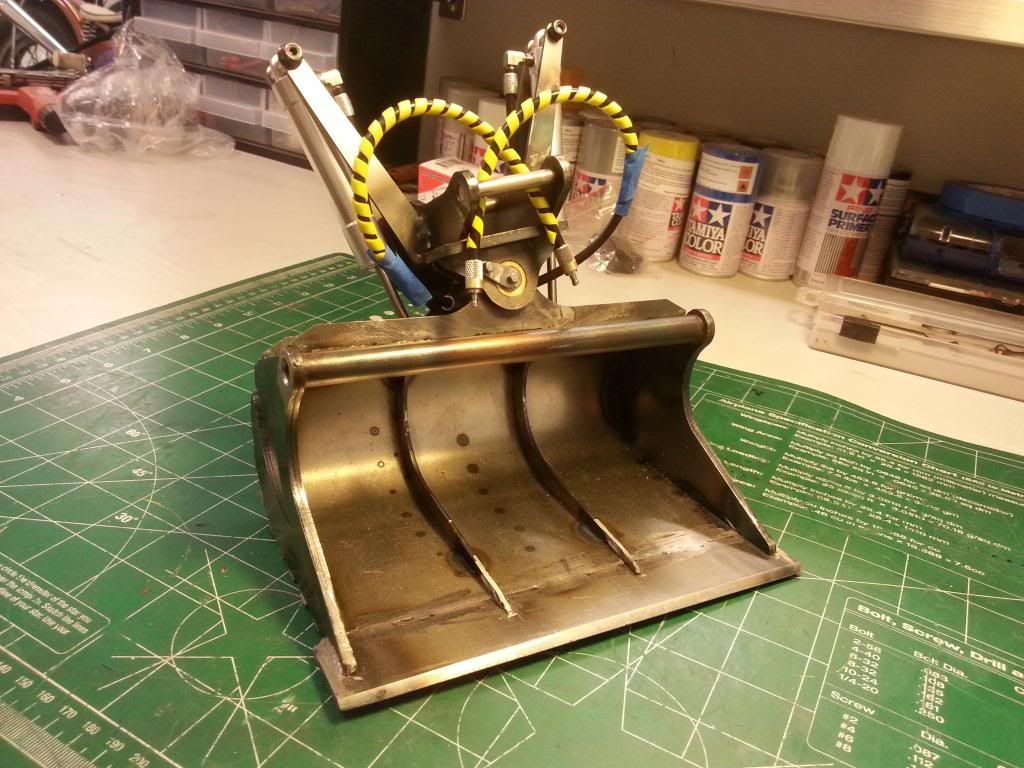

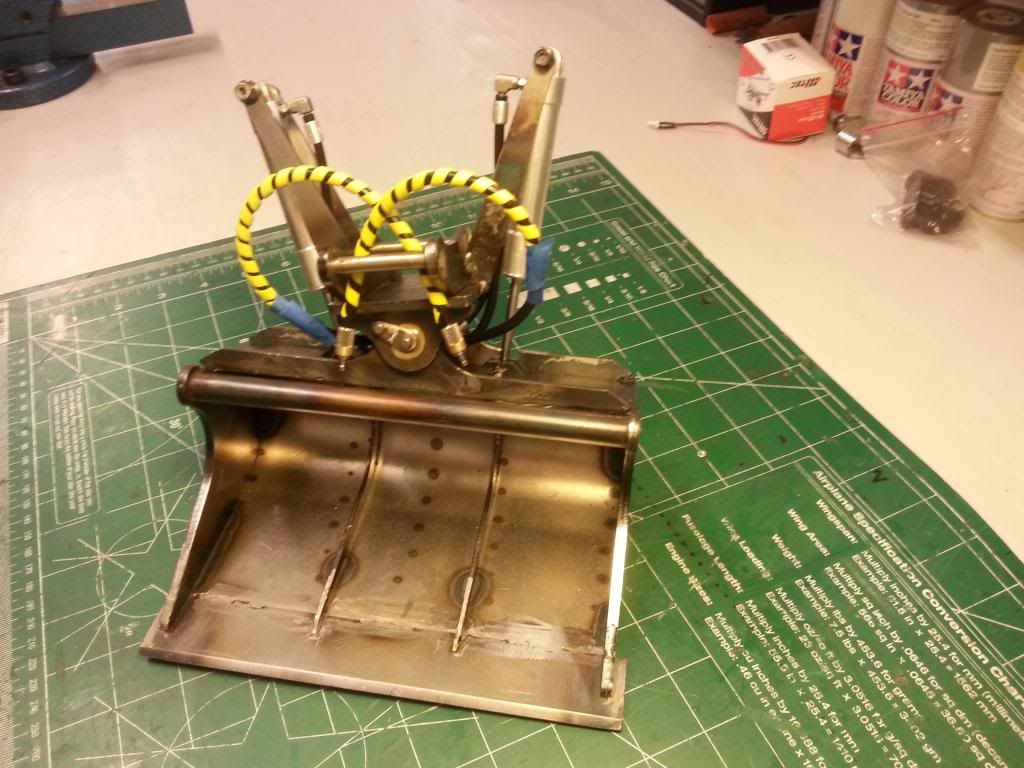

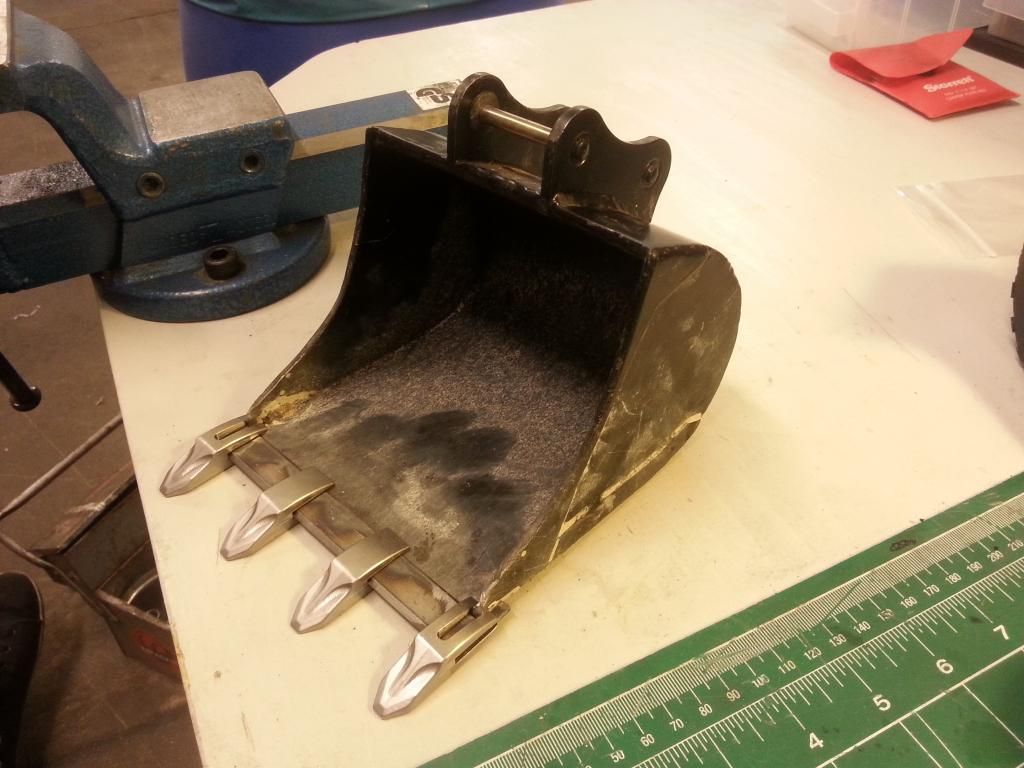

Nice looking tilt bucket!

Cheers, Neil. |

|

#9

|

|||

|

|||

|

Wow, awesome model. I move the real ones a couple times a week. We have about 20 in our rental fleet between Deere and Hitachi which are the same machine. Is that plumbing on the stick for the bucket or a future hammer???

|

|

#10

|

|||

|

|||

|

Quote:

Quote:

That's cool, I work with these machines as well, both excavators, wheel loaders and dumpers, though ours are Volvo, boss is a Volvo freak!  The plumbing on the stick is for the hydraulic tilt bucket, maybe for more attachments later. Thanks for all nice comments guys! Here are a few more pics of the bucket.

|

|

#11

|

||||

|

||||

|

Just read this from start to finish, honestly one of the best machines I've seen!

Well done on a superb model Calum |

|

#12

|

|||

|

|||

|

So freakin sweet! Great job.

|

|

#13

|

||||

|

||||

|

Very cool!!!

__________________

Always wasting money, as the wife says. To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#14

|

||||

|

||||

|

Definitely want to see a video of this working a ditch!!!

__________________

Always wasting money, as the wife says. To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#15

|

|||

|

|||

|

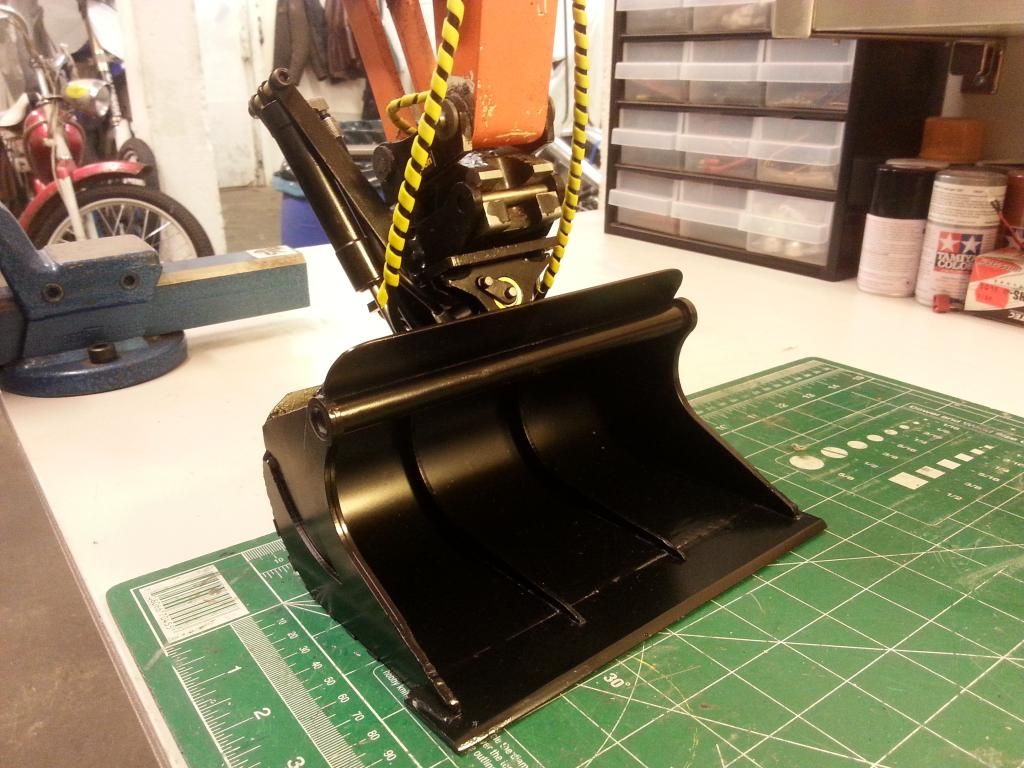

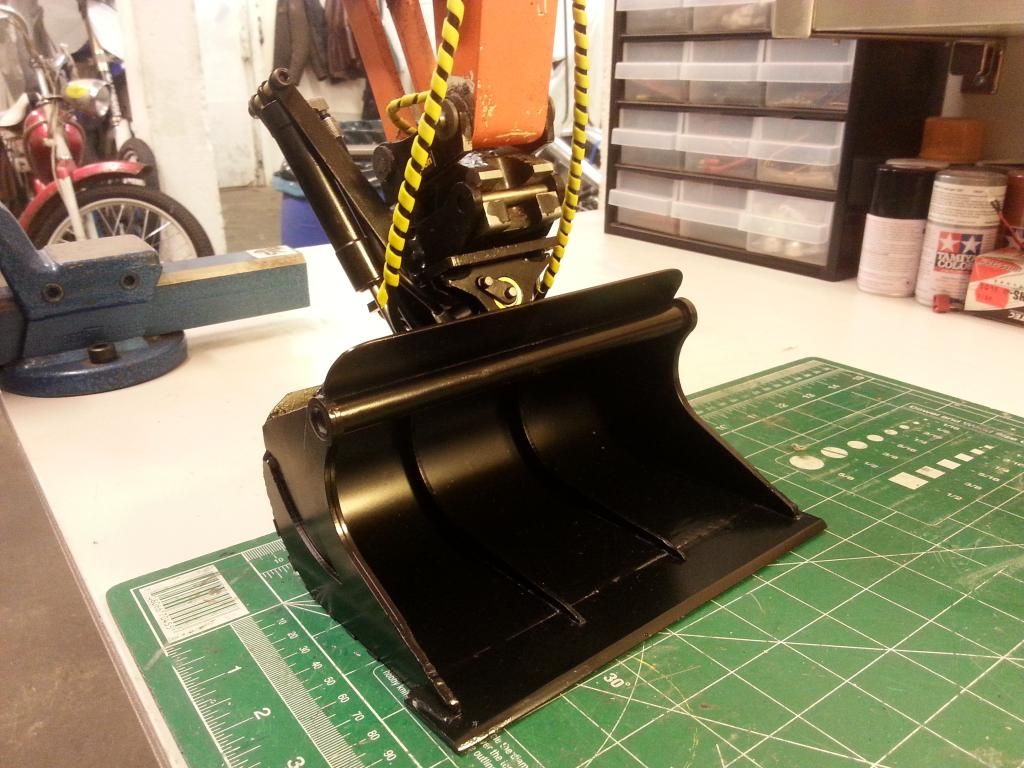

Thanks everyone!

I have finally painted it, but I do have some leakage problems with the M3x2mm swivel connectors on the lower hole on the cylinders, I have a hard time getting them to seal tight, I have had best luck with locktite 542 but also that gave after when I accidentally rotated the swivel, any tips on these or similar connectors? can't be much larger. Here's some pics and video.       [/URL] [/URL]

|

|

#16

|

|||

|

|||

|

Thanks everyone!

I have finally painted it, but I do have some leakage problems with the M3x2mm swivel connectors on the lower hole on the cylinders, I have a hard time getting them to seal tight, I have had best luck with locktite 542 but also that gave after when I accidentally rotated the swivel, any tips on these or similar connectors? can't be much larger. Here's some pics and video.       [/URL] [/URL]http://youtu.be/ZvwNPRKOOK8 |

|

#17

|

|||

|

|||

|

That is impressive! Well done.

|

|

#18

|

||||

|

||||

|

What you doing making movies indoors this time of yr Kalle?!

The swivel leak - what threads into the cyl or the hose on the barbed or the swivel joint itself leaks?

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#19

|

|||

|

|||

|

Thanks!

Quote:

Hopefully I'm going home soon and hope for good weather this time. The swivel joint, where it contacts the cylinder body, lower hole on cyl. It's the M3 one's, there isn't much thread that goes into the cyl and I also don't think that the little o-ring can handle the +20 bars, I got one tight but I think I was lucky there, I need to make a new more bulletproof connector I think, feels like they can start leaking anytime!  Or maybe turn some thin aluminum washers (0.8-1.0mm) instead of the o-rings?? Last edited by Azonic; 07-01-2014 at 11:50 AM. |

|

#20

|

|||

|

|||

|

Today I made a aluminum washer 5.5x0.5x3mm for the swivel connector, seem to work just fine so far, the washer and some Locktite 542 probably made it to seal like it should, more testing tomorrow!

Also started to wonder what to make of the original kit bucket, I dont have a straight cut bucket exept the grading bucket, but I really like it with the teeths!  What you think?

|

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

| Thread Tools | |

| Display Modes | |

|

|