|

|

|||||||

| Construction Equipment Tech Hydraulics, Electronics, General Engineering, ect in constr equip |

|

|

|

Thread Tools | Display Modes |

|

#21

|

|||

|

|||

|

I agree, if doing aluminum 6061 is probably best bet. Depending on cost, I would probably opt for hard anodizing to get some wear resistance at least for the track pads. Not sure how my anodizer would like that many tiny parts if doing the links though.

Now if went carbon steel it should be pretty good for wear on the pads, and pretty easy to black oxide all the pieces for a good look. If you get your design finalized and want a couple more prices ask Dan and I for quotes. One thing I notice in the pic you posted of your design so far. I see a thicknees bump out in the links around the pad bolt holes. That will add to machining costs, more so than just making the whole link thicker. Same for what looks like a raised boss around where the pins go through, but it may be e-clips, hard to see for sure.

__________________

Jeff Last edited by pugs; 02-23-2013 at 01:34 PM. |

|

#22

|

||||

|

||||

|

I know from using 7075 that it is pretty wear resistant in some circumstances, it is a harder compound and more rigid but it is terrible for being corrosion resistant, where as 6061 is softer but is very corrosion resistant and will not oxidize as fast as 7075.

I can't really help you with the life span but I think it all really depends on many different variables from what i'v learned; how tight your tolerances are with the parts, what type of material you will be running in, the weight of your machine, how much you use it, how hard you run it. Once you put hat all into account you could figure out what material to use. Personally from what i've researched 7075 will be great once it is anodized for many different machine weights, 6061 is also a good material, doesn't need to be coated but with the thin pieces it could bend easier and create binding which will drastically decrease the life span. Steel would be good but it wears the tooling required to make it much more than aluminum, it rusts the quickest, it may be strong but it is heavy so it will increase the wear on itself. That's what i've learned so far, out of everything titanium would be the best but I dont have deep pockets hahaha Hope this helps, Chris |

|

#23

|

||||

|

||||

|

Thanks for the pugs, got it all fixed up and simplified now, I'll post what should be the final design tonight if I get it all done and I hope to have my quote back within 4 days

Chris |

|

#24

|

||||

|

||||

|

I assumed the use variables would play a big role, but weight and side load etc i don't think would be as much an issue as in a 1:1, I'd think the areas of constant contact would wear at a lot faster rate than being worried about bending an outer end or even fatigue at the pin locations? Just due to the constant flexing and motion of it going around the rollers??

IMO 7075 would def. wear slower as you mentioned but it could cause quicker wear on other components where as the 6061 wouldn't. The corrosion issue is more what I was thinking would be an issue knowing the tracks will be used in dirt mud water etc. The hard coating should help with this and with any fatigue issues on the areas constantly rubbing each other. --Dan

__________________

To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#25

|

||||

|

||||

|

Yea good point, I geuss it will just matter once model start to reach 85+lbs.

If I get these made of 7075 we'll just have to see how they hold up! Chris |

|

#26

|

||||

|

||||

|

OK the ref has stepped in and cleaned this mess up.

Now if you have nothing positive to add to this discussion keep it to your self.  I think we are all here to help get ideas and see if this is a feasible option with a price reflecting the quality of material and craftsmanship. Play nice. Travis

__________________

AKA "00" Biddle RIP FreddyGearDrive 2-12-59/12-19-11 |

|

#27

|

||||

|

||||

|

I would say you would definitely need to hard coat the links but that adds alot of labor charges when they have to clamp each link in a inconspicuous area because the anodizing and black dye won't take in that area.

As soon as grit gets between the links the aluminum will gall up. If I get a chance, I am going to look into costs for the pads in aluminum and brass. |

|

#28

|

||||

|

||||

|

Quote:

Where is the "like" button..... --Dan

__________________

To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#29

|

||||

|

||||

|

Quote:

Depending on the size of the pin opening I already have rack fixtures setup to use 4 and 6mm rod, but have the ability to add smaller hanging rod on them. So he could hold them right through the pin holes?? If no one can get a decent price on it I'd be more than happy to see what he'd do for us --Dan

__________________

To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#30

|

||||

|

||||

|

I`ll let you know if I can get these anodized for a fair price or not, if not it would be awesome if he could anodize them.

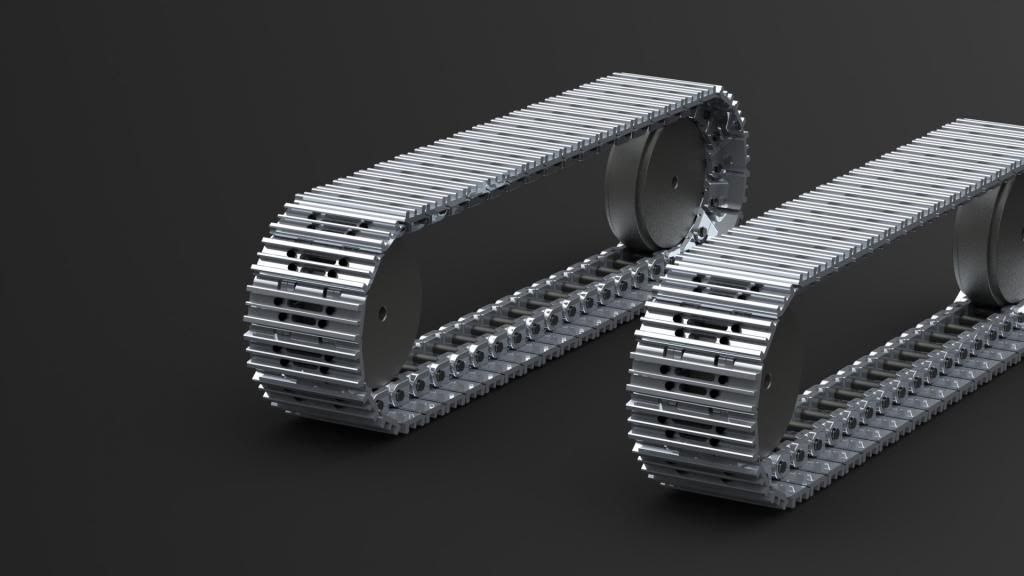

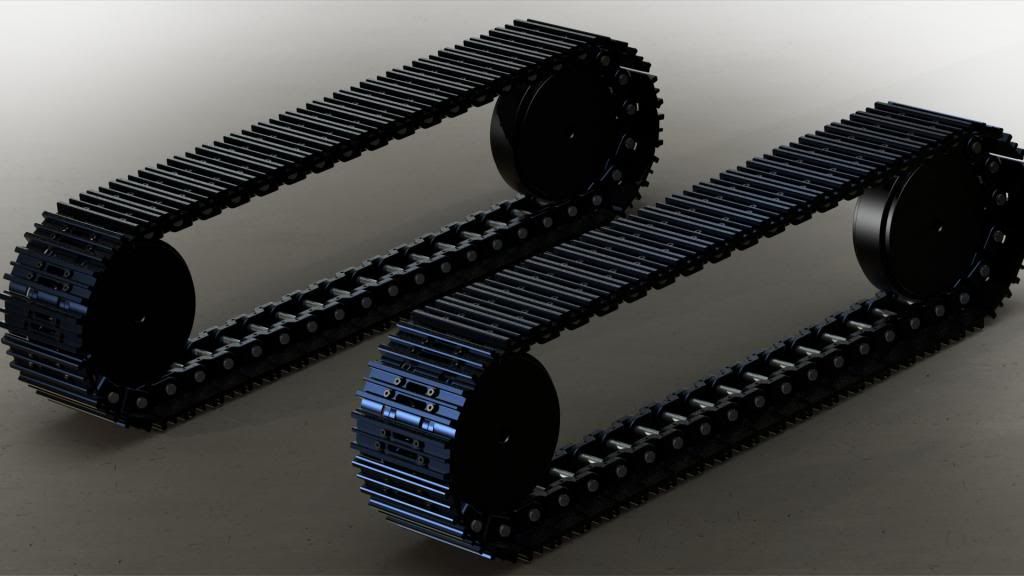

Because it sure looks sweet, this is what the final design will be, we are 99.9% done the design, just double checking all the dimensions so that they fit perfectly.  and a view of them anodized:  I can't wait to make some of these!! Chris |

|

#31

|

||||

|

||||

|

Nice!

I need to win the lotto cause my Volvo would look sweet with a pair of kicks like that! I need to win the lotto cause my Volvo would look sweet with a pair of kicks like that!

|

|

#32

|

||||

|

||||

|

Quote:

I deff like the idea of the black anodized pads really cool idea!

__________________

Hi my name is Aaron.... And i'm a truckaholic! |

|

#33

|

||||

|

||||

|

What's the height of the grouser bars?

A nagging problem I have with the tracks binding on my Vario is the amount of moist dirt that gets packed between adjoining pads... been thinking of milling down the bars or even putting a slight taper on the outer edges of each grouser bar so the dirt might squeeze out. Does this makes sense to you or do I need a picture to explain it? Currently I have a 2 bar pad which is great for climbing & staying planted with hard digging, the downside however is trying to turn, sometimes it will skip a track off.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#34

|

||||

|

||||

|

the actually height of just the tread bar (i think thats what the grouser bar is haha), is 3.5mm

Do you mean where the two pads overlap one and other? Chris |

|

#35

|

||||

|

||||

|

No, the space between the tread bars of two seperate pads.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#36

|

||||

|

||||

|

Ahhh okay, these tracks have a 1.50mm gap when they are flat so I'm not to sure how that will work.

I wonder how to stop it from clogging? Chris |

|

#37

|

||||

|

||||

|

I've been thinking/hoping a tapered edge might squeeze the dirt out as the pads come together on the horizontal.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#38

|

||||

|

||||

|

hmmm that might work pretty good. especially if it doesn't compact cause it would always be getting compressed and then fall out. Ill see if I can add something into the drawings.

thanks for the tip Chris |

|

#39

|

|||

|

|||

|

Shouldn't all the grouser bars be tapered a bit, I think that's how the real ones are.

__________________

Jeff |

|

#40

|

|||

|

|||

|

I was waiting until I had enough posts (not sure if I am even allowed to post this) and if I need to move or delete it, let me know.

I am really into fine detail as most of you are so, whatever I do will have as much of it as I can put in it. That being said, I thought I should jump in here and put in my 2 cents since I already have an enormous amount of time invested in it. Business is slow and I am putting the shop to good use. IH builder, you are correct about extrusions and punching the holes and such as I am making the (punch) dies for the 1/14th scale size pads for a 80,000lb class dozer/excavator in the shop now. The following samples are what the end product will look like cut from the stock minus all additional processing. I cut these out on my wire machine so, the finish is nice but, the extrusion finish will be more of a mill finish like any other extrusion, once it is in the dirt for a while it won't look like an extrusion anyway. This will be run in 6063T5 not 7075 because extruder cannot run it and I don't think there are not too many that have the capability here in the states that can with this size shape. I really don't think it would be worth the extra cost to do it either??. The complete unit in black, is the scale version rendered on a 3D printer, it is very accurate considering the rough finish. The bolts are 0-80 and fit right into the holes perfectly. The links are going to be of both steel and aluminum base if possible, will let you know how that goes shortly, the file is out for feasibility and quote. These pads will be bolted with 0-80 or 1.5mm scale bolts specifically for this purpose. I do have pricing for the pads in aluminum, not sure if I am allowed to post here if at all. Steel pads are also going to be an option, something I would like to discuss along with several other issues with everyone at the right time. I am going to stop blabbing until I know what, where and if I can keep talking. I hope this input is helpful. For some reason I can't upload the pics, I will keep trying. I will also try posting the pics at the track topic I posted a while ago. |

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

| Thread Tools | |

| Display Modes | |

|

|