|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

|

Thread Tools | Display Modes |

|

#1

|

||||

|

||||

|

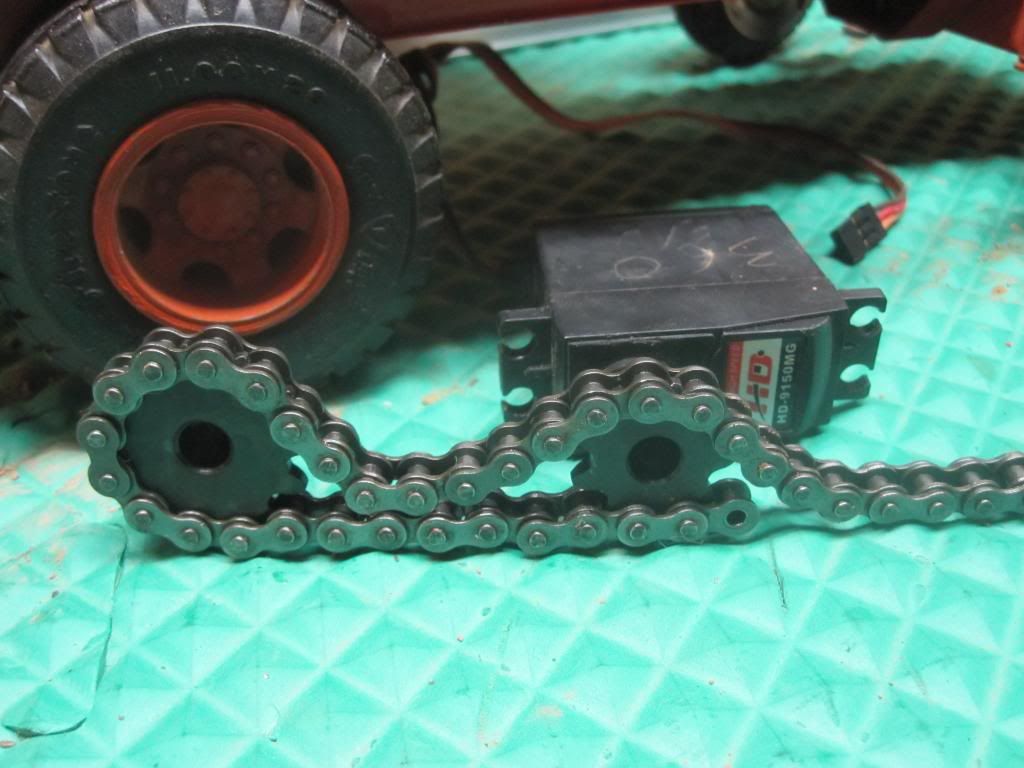

Well, since I have some pics to share it is time to start a thread for the Unit Hoe. All I have so far is the crane, drive chain & the drive gears. I ordered the chain for the tracks and the aluminum for the track pads. I also ordered some 200oz-inch metal gear servos that I am going to try to run the tracks. I still need to remove the cab from the frame.

1:1 for reference:

__________________

Scott "No load is too Small" |

|

#2

|

|||

|

|||

|

This is going to be a nice build. I going to watch this one

|

|

#3

|

||||

|

||||

|

Looks like a fun project, looking forward to watching this build. Servo city has the #25 sprockets that mount right on to servo's as well..

greg |

|

#4

|

|||

|

|||

|

Great! Watching and waiting...

|

|

#5

|

||||

|

||||

|

Are you making flat track pads or the "High Walker" version?

|

|

#6

|

||||

|

||||

|

Thanks

Quote:

Thanks Steve, I am going with the high walker version so that I can climb steep hills with it.

__________________

Scott "No load is too Small" |

|

#7

|

||||

|

||||

|

You may need a dozer with a winch too for the really steep hills. It could pull you up as the pipe line advances.

|

|

#8

|

||||

|

||||

|

wow is this the same one or another Unit? LOL no pun in 10 did.

__________________

Rc's are like pringles. You can't have just one!! my YouTube is - To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. Subscribe!! My Facebook - To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#9

|

||||

|

||||

|

Quote:

No, this Unit is another unit.

__________________

Scott "No load is too Small" |

|

#10

|

||||

|

||||

|

Hey Smallhaul

Great idea for a build.  Looking forward to seeing this build.

__________________

To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#11

|

|||

|

|||

|

Very cool, always thinking outside the box.

|

|

#12

|

||||

|

||||

|

Quote:

Thank You Scalerlover! Well, I got the track chain today and I am very happy with the size & style. Still have lots of parts coming.

__________________

Scott "No load is too Small" |

|

#13

|

|||

|

|||

|

The track chain looks great. Where did you order from?

|

|

#14

|

|||

|

|||

|

Hello Scott I see things are really coming together for you glad to see it. You are moving along quite fast on it before long you will be digging ditches. Keep up the good work. Ed

|

|

#15

|

||||

|

||||

|

Thanks, I got it from a local supplier but, just search for chain suppliers near you and then call them and ask for size 35 chain with K1 links every other link. They can order it for you because many places manufacture it.

Thanks Greg (RCLogger) for all the info on the chain!  Greg, you have helped me so much on this build, I think you should name the Hoe. Greg, you have helped me so much on this build, I think you should name the Hoe.

__________________

Scott "No load is too Small" |

|

#16

|

||||

|

||||

|

Quote:

__________________

Scott "No load is too Small" |

|

#17

|

||||

|

||||

|

I was just thinking Scott, The new boom section on the drag; You should put some cold gun bluing on it rather than painting it black.

Those washers lined up on the tracks reminds me of an old Thew shovel or the BIG Bucyrus Shovels. |

|

#18

|

||||

|

||||

|

wow that looks awesome!! this one is gonna be a heck of a tracker!

__________________

Rc's are like pringles. You can't have just one!! my YouTube is - To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. Subscribe!! My Facebook - To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#19

|

||||

|

||||

|

Hi Scott. I'm really looking forward to seeing this come together! It should be a really neat model, when done. I'm also looking forward to hearing your thoughts on the servo and chain drive. I've seen those goodies for sale online, and it's really easy to dream up all kinds of drives and uses for a continous rotation servo and the sprockets that fit them. It's pretty amazing. Stuff like that never used to be so readily available!

__________________

Nathan |

|

#20

|

||||

|

||||

|

Thanks for the interest Nathan! I am really looking forward to building this to. I like the complexity of it. It will have gears, pulleys, sprockets, chains, cables, tracks & drums.

__________________

Scott "No load is too Small" |

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|