|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

|

Thread Tools | Display Modes |

|

#1

|

|||

|

|||

|

My next project is going to be Cat 374D excavator in 1:14 scale

We shall see how it turns out since I have never build anything on tracks. I was not able to find tracks that are wide enough, so I try to do my own. Here´s a picture of the original and a few track links I made.

__________________

Ari To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#2

|

||||

|

||||

|

After seeing what you accomplished with your grader, this should be easy! Wow. Your sample track pads look great. See, you've already got it figured out!

__________________

Nathan |

|

#3

|

|||

|

|||

|

Awesome, another master piece in the making no doubt! Where do you source the bolts that are holding the cleats on? Here in NZ, I'm struggling to find anything approaching these small sizes, even in M3.

Glenn |

|

#4

|

|||

|

|||

|

Glenn: I get small bolts from Knupfer Germany: http://www.knupfershop.de/shop/index...9a&cp_tpl=main

Here's the drive sprockets:

__________________

Ari To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#5

|

|||

|

|||

|

Ohh man, i didnt think you would start this one so quickly, its all good for me!

Those track pads looks amazing, what material are they? Cant wait to see more of this one, with your skills it will be a 1:14 replica! |

|

#6

|

||||

|

||||

|

looks like another great build so far , Ari . seeing those pads , makes me want to continue with what I all ready have programed for my TD40B . the links will take me 40 Hrs alone on the VMC just on 1 side of them .

__________________

RIP FreddyGearDrive 2-12-59/12-19-11 To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#7

|

||||

|

||||

|

Looks fantastic Ari! This will look sweet beside your grader! How long does it take to machine a pad and link?

Reg |

|

#8

|

|||

|

|||

|

It takes about 25 minutes to make one link pair and pad

I have only made two of them, and it just hit me that making the rest 100 pcs will take very long time I have only made two of them, and it just hit me that making the rest 100 pcs will take very long time

__________________

Ari To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#9

|

||||

|

||||

|

Quote:

. You may be there for what seems like forever but it will look perfect when it is finished. As a mechanic friend of my Dads always says "time, patients and perseverance"! . You may be there for what seems like forever but it will look perfect when it is finished. As a mechanic friend of my Dads always says "time, patients and perseverance"! Reg |

|

#10

|

|||

|

|||

|

Very nice start on a great project-have you decided how you will hold the drive pins in the track links?

|

|

#11

|

|||

|

|||

|

Does any of you guys have an idea how is the Variable Gauge Undercarriage actually made in 374.

I do understand that it's a way to narrow the machine when transporting it on public roads, but can't figure out how is the "sliding mechanism" done.

__________________

Ari To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#12

|

||||

|

||||

|

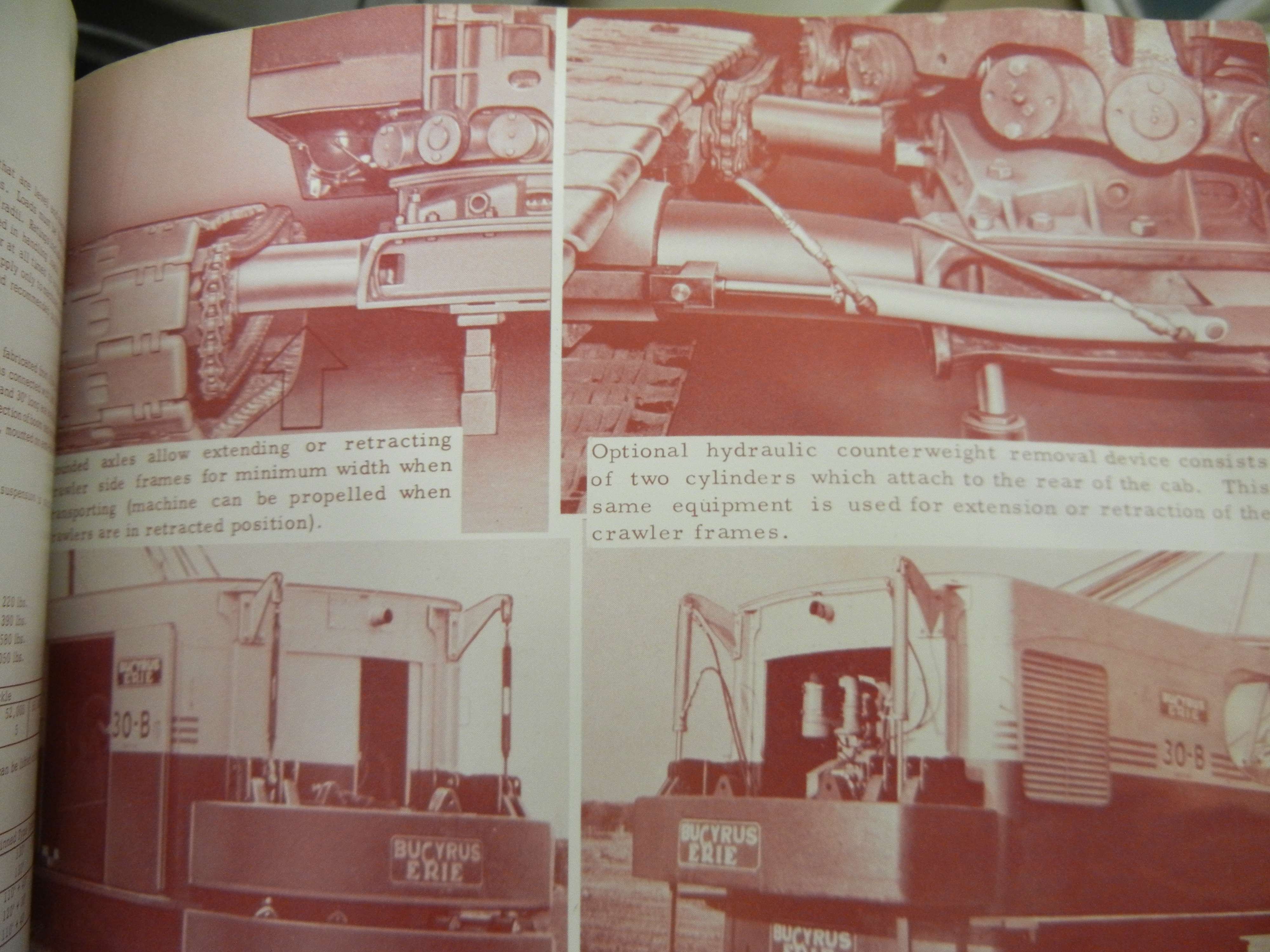

I never saw one closeup of this modern of a machine but on some of the old Bucyrus-Erie machines they would telescope in and out and some had hydraulic rams to do this.

|

|

#13

|

|||

|

|||

|

Mechanical ones have a sliding pad front and back in the track assembly, with the beam of the turntable having extra long arms.

So far best pics I can find are here at 1:08 http://www.youtube.com/watch?v=OmQXDLOO7wo

__________________

Jeff |

|

#14

|

||||

|

||||

|

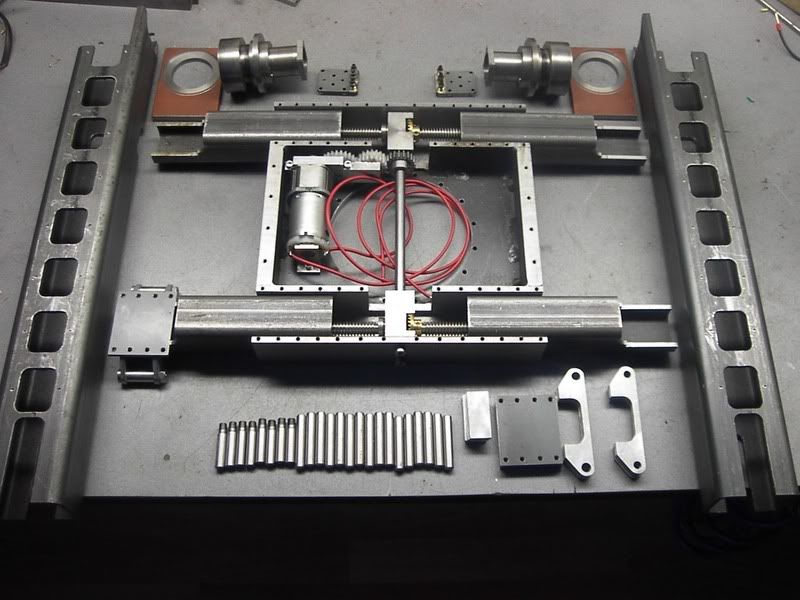

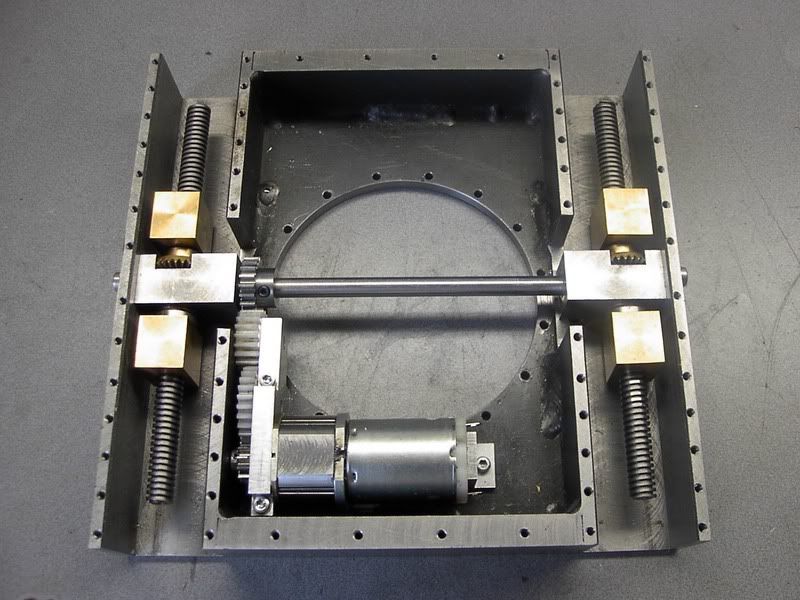

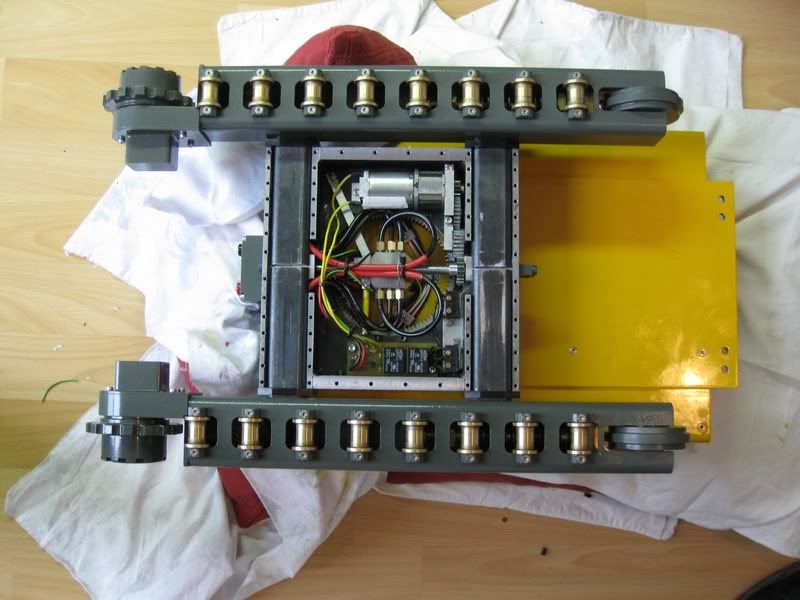

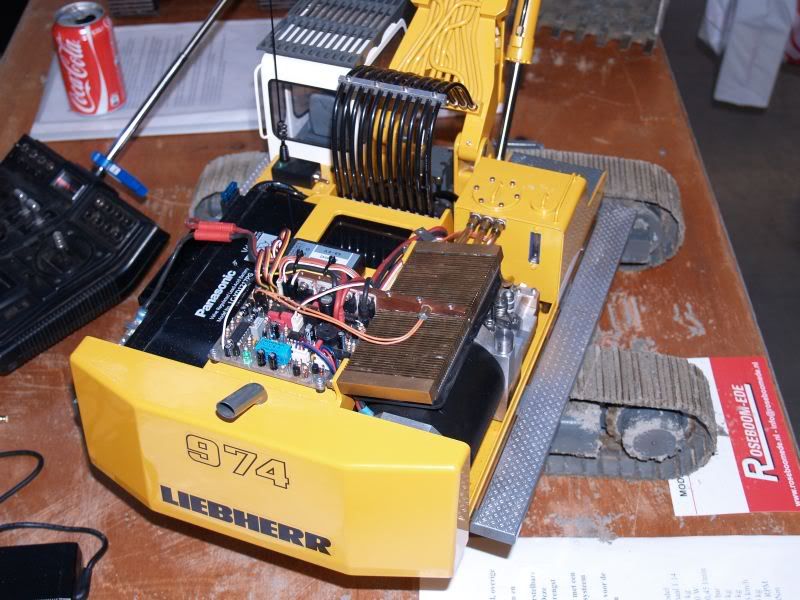

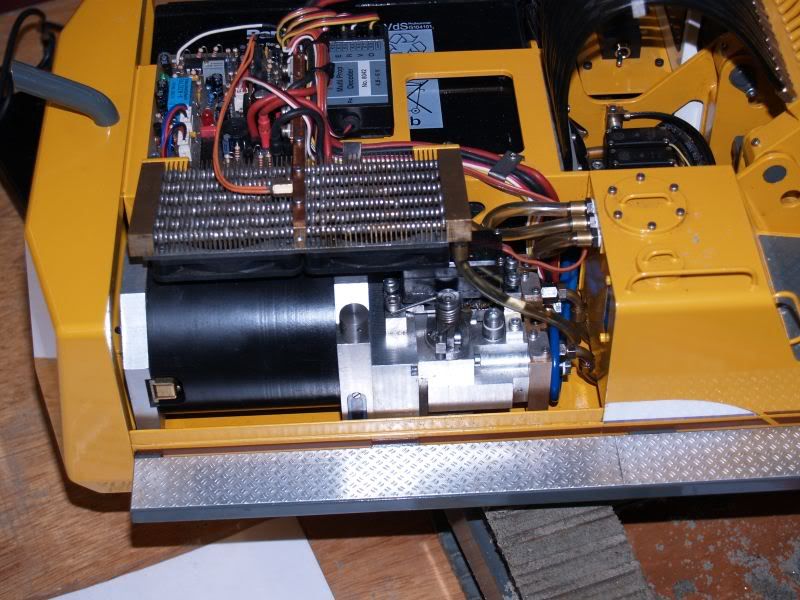

I have some pictures taken from the dutch forum from someone that build a Liebherr 974.

It's a digger in the same 75 ton class as your Caterpillar. Normally the tracks can slide seperate left and right, but he build them sliding at the same time. It's not a problem, if you slew the uppercarriage to one side, the weight is to one side and you can slide the tracks in and out without any problems, or lift the machine with the boom. This Liebherr is build suberbly,build from steel and weighs 50 kilogram, runs on 60 bar and is completely hydraulic ( also slewing and driving), except for the tracks sliding in and out. It has two radial piston pumps with a variable slideplate, so it has load sensing. The pictures of the under carriage:      I made some pictures of this machine at the Modelshow Europe:        Here some films for a general impression: http://www.youtube.com/watch?v=a2X3OKDglAU&feature=fvst http://www.youtube.com/watch?v=vqcYg...eature=related He went to some shows in Germany and they call it "the mother of all diggers" I can not tell you any more details, I don't know the builder, but this digger is famous. I hope this info helps.

__________________

Greetings from Holland, William |

|

#15

|

|||

|

|||

|

Thanks guys for your help, but it appears that Cat did this little different.

For me it appears that the track housing slides under the x-frame and there's some guide rollers on the side  (some of it can be seen on the pugs video link) (some of it can be seen on the pugs video link) In the first picture you can see that the 374 is narrowed for transport, and in the second it's wider. It's a little bit confusing cause there's seems to be some differences between the 374, but if I understand correctly the Variable Gauge Undercarriage is standard in all 374. There are plenty of pictures of the 374 in action but naturally the undercarriage is often so dirty you can't see too many details on them.

__________________

Ari To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#16

|

||||

|

||||

|

It looks like it's a sliding plate, but there is a great possiblity that in wide spread the plates are bolted on. That's not oncommon on these heavy machines, so the narrow position is only for transport, and the excavator cannot be used in this position.

You should considder this option then as useful or not, if you are going to use the excavator for what it is build, namely excavating, I think it's an option that is sensitive to malfunction. If you are going to dig in the sand of course, because that kills the undercarriage.You are building some strong tracks, they will hold for shure. Here's a picture where you can see the undercarriage is on the tracks and not beside:  Transport in wide configuration:  This one looks like a one piece undercarriage, not so strange:  If a machine is running on closed ground for it's whole life, why have an extentable that's more fragile and sensitive to malfunctions. And in the wide configuration you can still transport the machine, it's not a machine that is running jobs for a few days and then transported again.

__________________

Greetings from Holland, William |

|

#17

|

|||

|

|||

|

Thanks William, you are probably right about that it's bolted on when digging

It's true that excavator this big does not change job site so often that the bolting it solid is not too big of an issue. Actually this information made my life easier  , that is if I make it permanently wide. , that is if I make it permanently wide.

__________________

Ari To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#18

|

||||

|

||||

|

Ari , in my research on the 385 CL , IIRC , I read that the track frames are just either bolted wide or narrow depending on application .

__________________

RIP FreddyGearDrive 2-12-59/12-19-11 To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#19

|

||||

|

||||

|

Hi Ari,

If Steve found the info on the 385 it's probably the same for the 374. To give you an idea, I have some pictures of a Sennebogen lattice boom crane. This one has a sliding track, but it's also constructed to use for a longer time. Here you see it in transport situation, and the slides are sticking out a bit:  But when it is in use some additional steel blocks are screwed to the side to make the carriage wider. These blocks weigh a few hundred kilo's and there are I believe 9 strong bolts. This is not a daily exercise, but when you move the crane every few months, it's happening maybe 3 or 4 times a year, something you can overcome.  A closup from the block:  And sometimes they don't even bother to take them off!! If you already have a permit for the transport, better give the dimensions with the blocks:  Just to give you an impression how it's done with a crane. This same type is also delivered with removable tracks, they can lift themselves up and take the tracks completely off:  This all is off course different from an excavator, but you see what type of solutions there are for transporting large equipment.

__________________

Greetings from Holland, William |

|

#20

|

|||

|

|||

|

Thanks guys for your effort, I learn something new again

Today I got the drive hubs and covers done:

__________________

Ari To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|