|

|

#261

|

|||

|

|||

|

where did you find that tire and how big is it? cute lil doggie lol

__________________

I built this thing and have it working now what do I do with it? |

|

#262

|

||||

|

||||

|

I had that laying around,don't know where it came from. It does measure :6.5''od x 2''w x 3.25''id.

|

|

#263

|

|||

|

|||

|

wow thats soooo close to my scraper tire lol

__________________

I built this thing and have it working now what do I do with it? |

|

#264

|

||||

|

||||

|

Really cute dog. I'm not used to little guys 'cause we have two retrievers. Anyway, the tire reminds me of the ones that came with ashtrays in the center - all the tire manufacturers made them in the 60's and 70's. You can find them on evil-bay but might have difficulty getting enough of the same for a set - and usually not cheap.

Ken |

|

#265

|

||||

|

||||

|

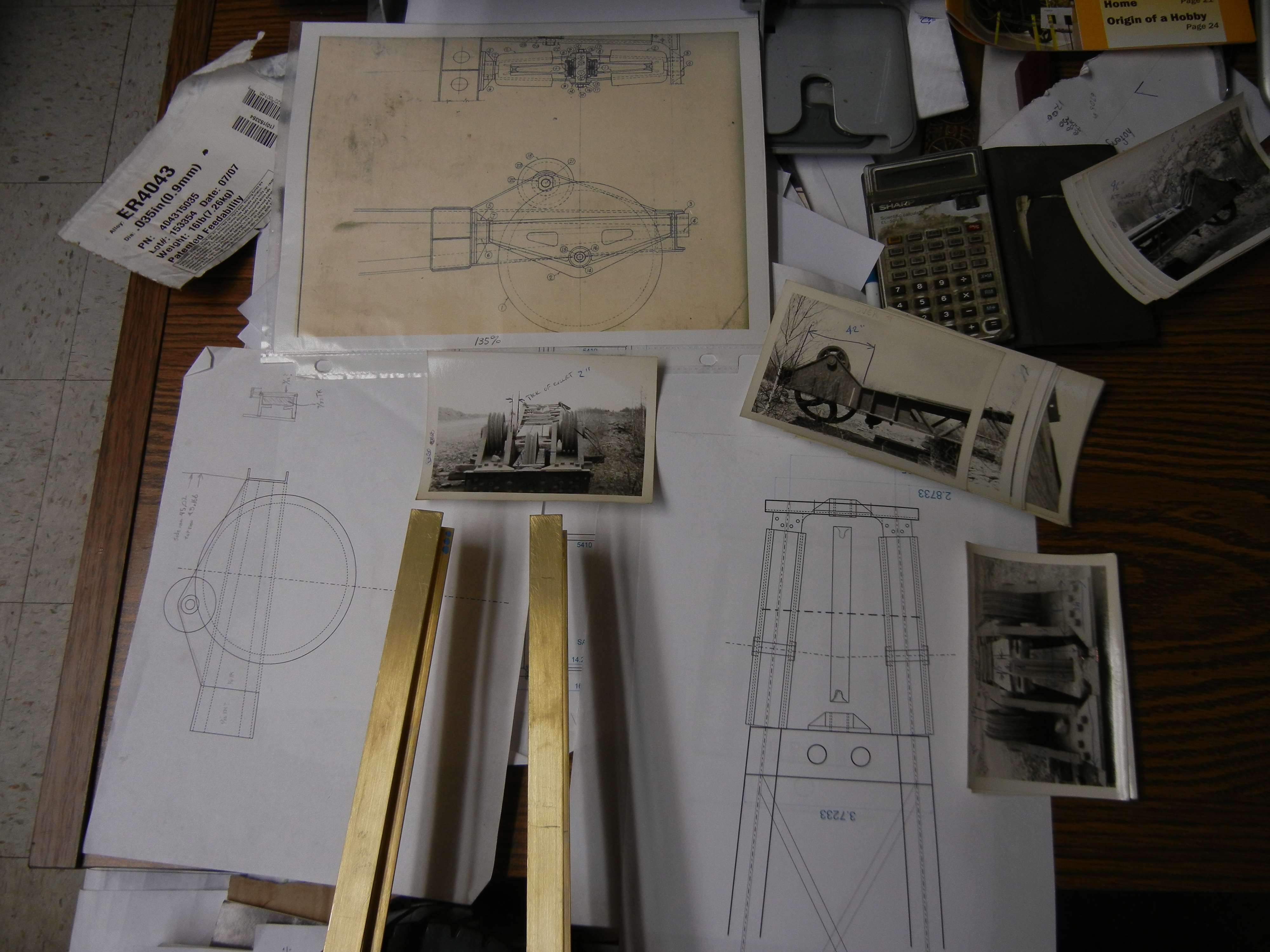

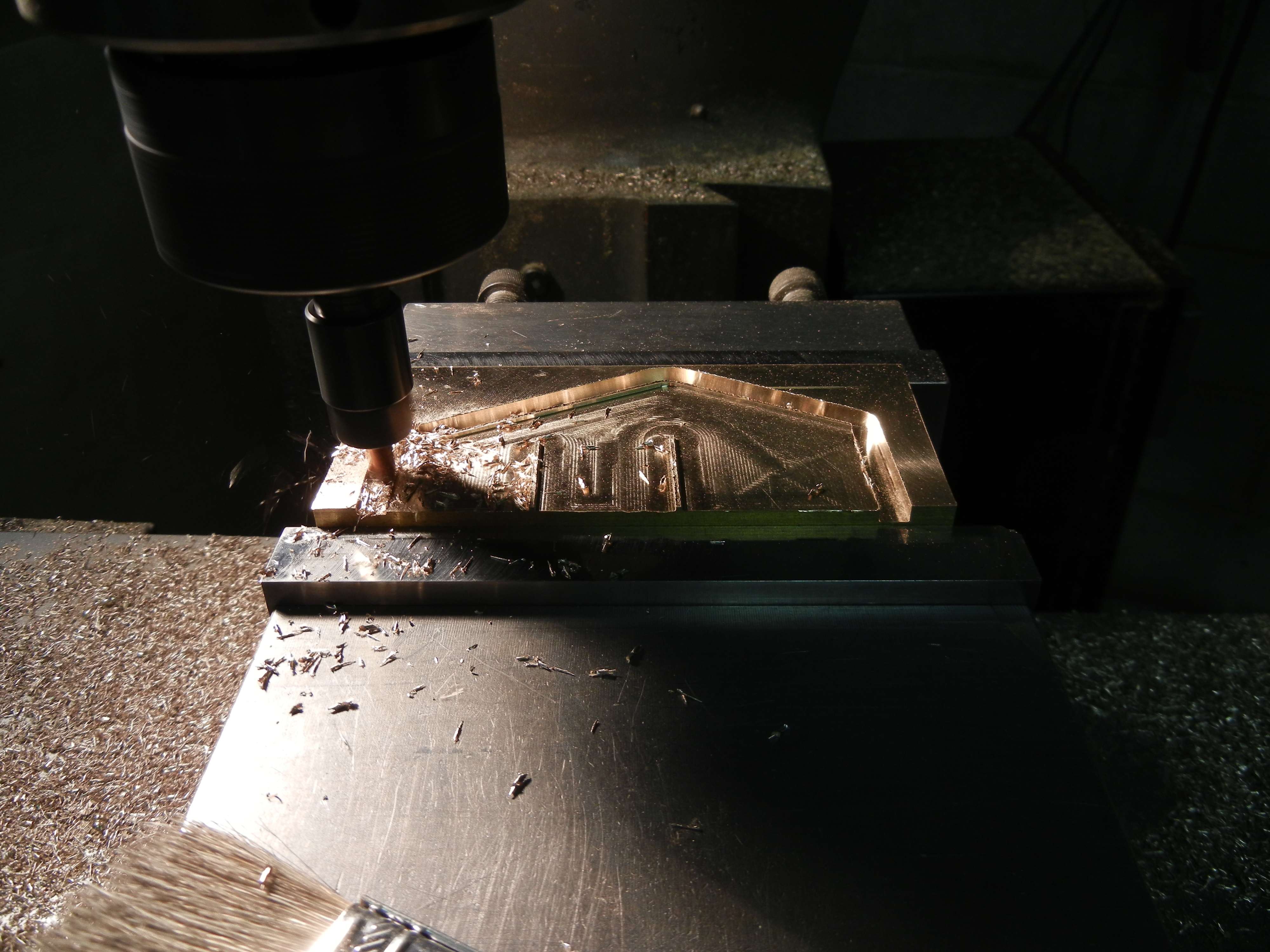

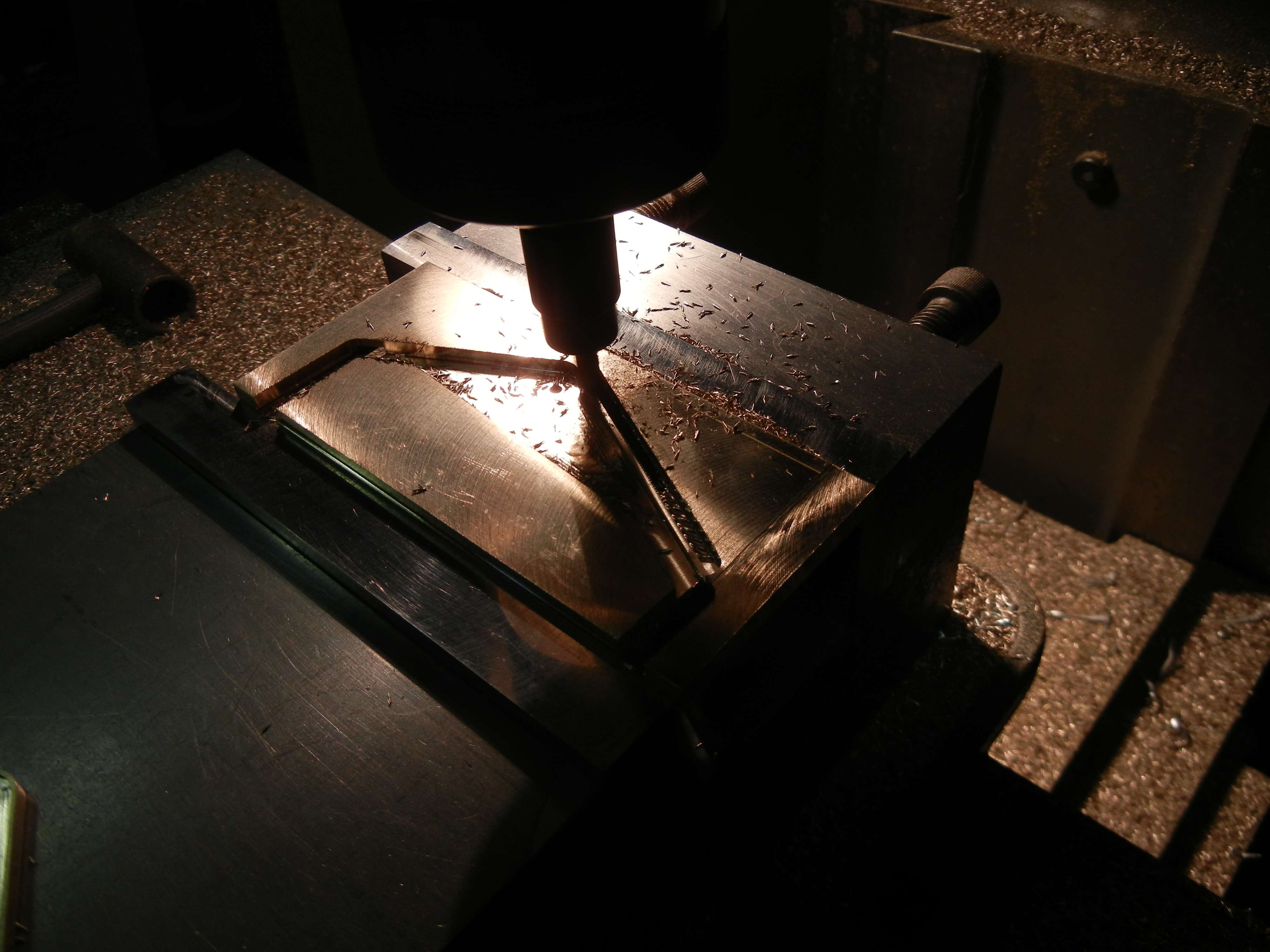

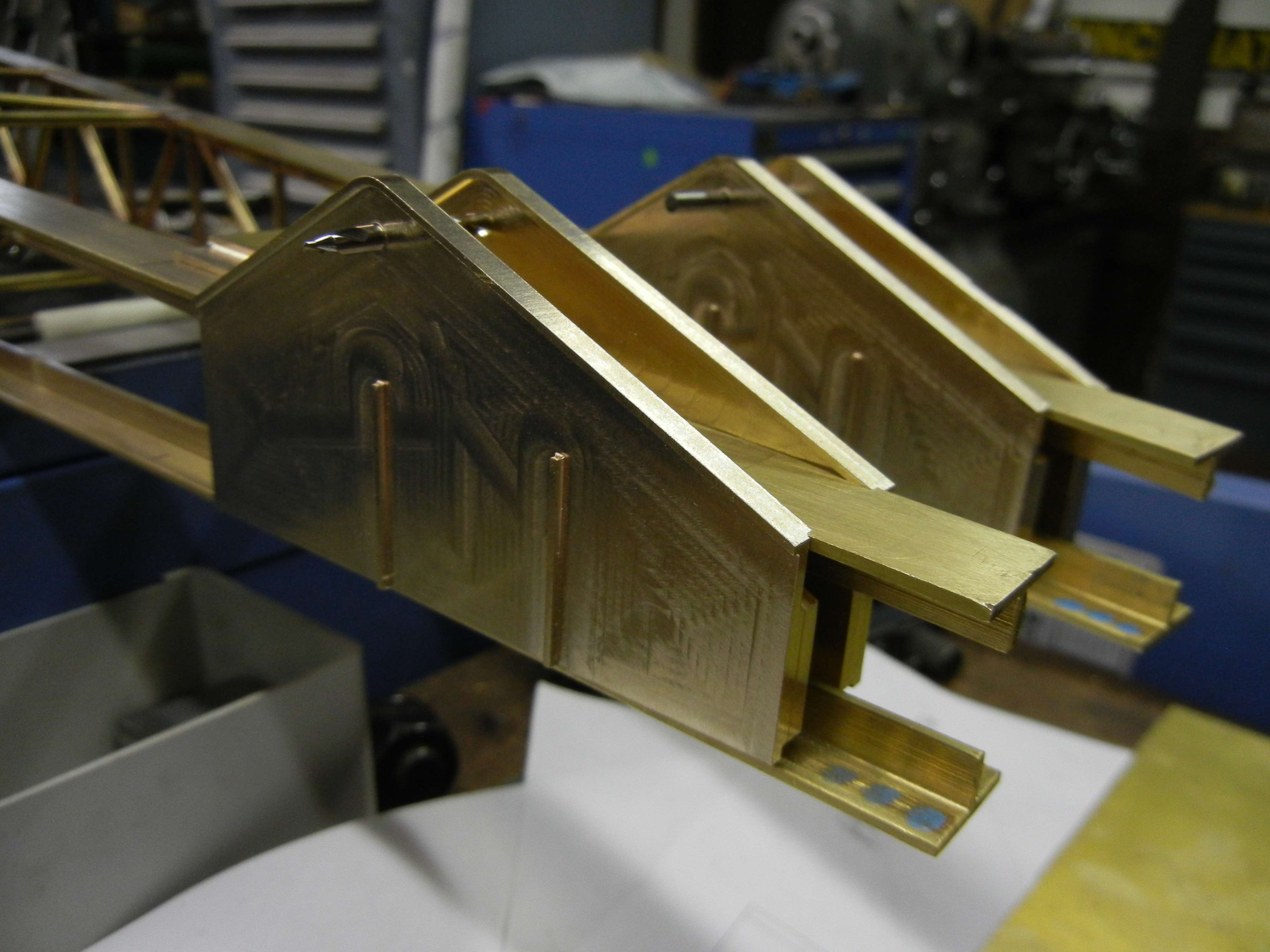

Made some slow progress today. I real time consuming job of pocketing. I had to take small cuts because my cutter is dull and the plate is thin and is done on both sides. The B/W photo is from a different machine but literally the same other than the point. That photo was taken 42yrs ago.

|

|

#266

|

||||

|

||||

|

its looking good!

__________________

Rc's are like pringles. You can't have just one!! my YouTube is - To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. Subscribe!! My Facebook - To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#267

|

|||

|

|||

|

Looking good steve-I don't understand the 2-small sheaves over the boom point sheave. What's that all about?

|

|

#268

|

|||

|

|||

|

Looks nice, huch much time do a part like that take in programming, preparation and production??

Dan |

|

#269

|

||||

|

||||

|

Those are for the suspension cables. There are 6 of them up there and two smaller for the cable ends. This machine has a "Live Boom" but after it's at the proper angle there's two sets of safety cables attached to the mid points. You'll see when I get to that stage. The B/W picture is a boom from probably a 6160 with a two part hoist,notice the attachment under the boom and it has a smaller diameter sheave. This one is: 44''dia. and mine will be:58'' (3.625''scale)

|

|

#270

|

||||

|

||||

|

Quote:

That reminds me, I want to order a new carbide endmill to do the others. That reminds me, I want to order a new carbide endmill to do the others.

|

|

#271

|

|||

|

|||

|

Steve that is some very nice work as usual from your shop. Ed

|

|

#272

|

||||

|

||||

|

Quote:

How many channels does that take to run? Looks like you got a couple inverters for the 12v? or 24? Could you take a brief min. and kinda explain to me how the machine is wired? like inverter to? to? and motor goes to? and so on. You can PM me if you don't want to clutter your thread up. I'll have a bunch of ? Thanks Matt |

|

#273

|

||||

|

||||

|

Quote:

As far as channels, I'm using 3 : dragging/walking,hoisting, swinging, I will need a couple more to set the drag and walking brakes.One for the walking jaw clutch. Maybe another for turning the lights on off. Horn? I have a DX7 radio (overkill) 110VAC Power is run into the tub then through a 6 conductor slip ring. then the power goes to a relay that is manually controlled back at my power box for safety purposes to kill it if something happens or someones fingers get in there. After the relay the voltage is fed to the 3- 90VDC 4 quadrant regenerative drives and a 5VDC power supply. The RC part comes from the 3 ESC's attached to the reciever and then each is individually wired to the 3 regen drives. Power to operate the Receiver and ESC'c comes from the 5VDC power supply. The ESC's put out a +5 or-5V signal and that is fed to the drives and they start when the voltage comes in. The drives are then wired to three 90VDC perm. magnet motors,1/29hp=hoist 1/17hp=swing 1/8hp drag/walk. The whole deal draws only 1.5a not to mention when I'm lowering the hoist, I'm generating power back into the incoming 110VAC line. Pretty simple only took me 8yrs and a bunch of $$ and trial and error. My big plan is to hard wire the whole machine and control it with the original operators controls from a 1:1 machine. All I have to do is pull all the electronics off and put them back to my operators station and put a slip ring in with more conductors. I could also tear apart my radio and install the pots on the stick to my 1:1 controls. RC just made it alot easier to do. |

|

#274

|

||||

|

||||

|

A little more update on the boom point this past week.

Four sides now done.

|

|

#275

|

||||

|

||||

|

oh my that is nice!!

__________________

Rc's are like pringles. You can't have just one!! my YouTube is - To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. Subscribe!! My Facebook - To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#276

|

||||

|

||||

|

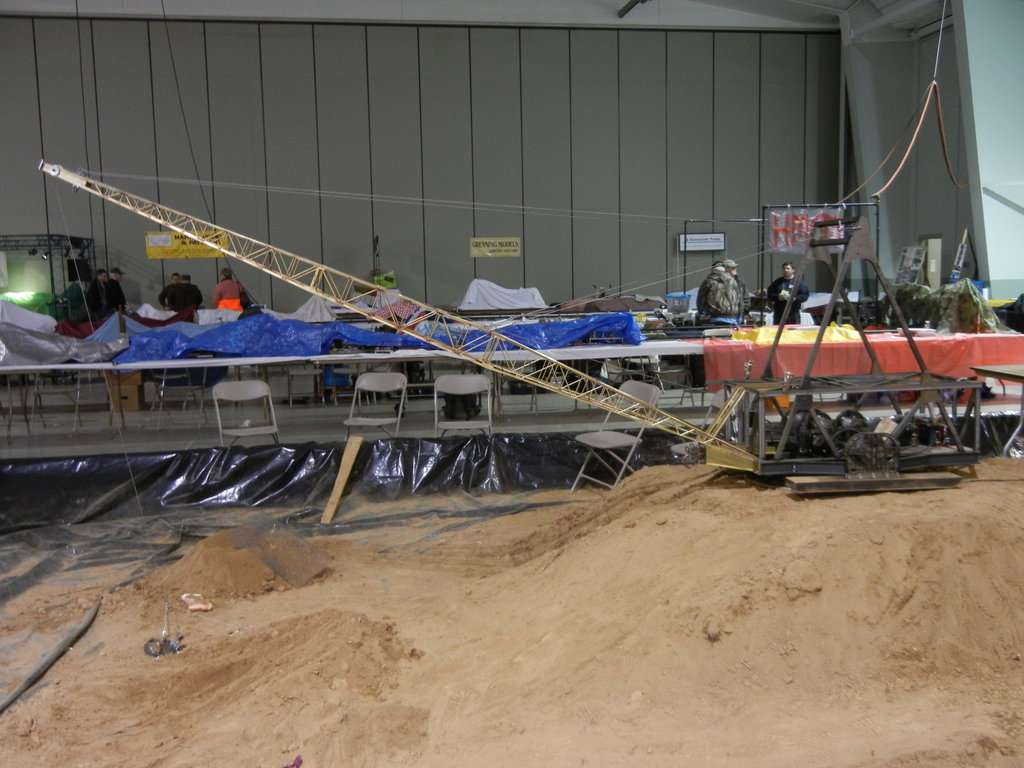

Nice progress Steve Is that first pic from cabin fever?

Brian |

|

#277

|

||||

|

||||

|

Yes Brian, I took that Saturday night when they kicked us out. Get that triaxle done so you can haul at the next York show.

|

|

#278

|

|||

|

|||

|

Looks great steve! Always waiting to see more!

|

|

#279

|

|||

|

|||

|

looking good as usual, Steve. Looked the vid with one of my friends (who also visit Brownsville) , he has more than 20 real machines,. A question, it looks like there to little weight in the bucket, is this only a test bucket? You had a bigger one on side of machine, is that the one that will be used??

Dan |

|

#280

|

||||

|

||||

|

Quote:

. It used to be pressed on slightly. I couldn't pick the big bucket up empty . It used to be pressed on slightly. I couldn't pick the big bucket up empty . After 6yrs I guess you find these unseen problems,after all it was only the second time this has been in the dirt actually working. It's fixed now and I wish I found the problem at the show. I think I described this problem earlier. . After 6yrs I guess you find these unseen problems,after all it was only the second time this has been in the dirt actually working. It's fixed now and I wish I found the problem at the show. I think I described this problem earlier.I'll have more pictures soon on the boom point. I just cut a piece of 3.75'' round stock this morning for the point sheave. I'll be working on the cradle that holds the point sheave tonight. |

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|