|

|

#81

|

|||

|

|||

|

Quote:

What will you be changing to? I'm curious to know, before Flicker explodes like Photobutt did. |

|

#82

|

|||

|

|||

|

It's been long days at work this week, (I'll take ALL the hours I can get now, cause I know they'll dry up in a few more weeks) already got almost 48 hours in for this week, after a 10 hour day today. Since it wasn't a terribly long day, I opened a ton of mail that had accumulated this week. I didn't take pictures of it. The new servo mounted winch spools for the log skidder arrived today. I'll have to modify them a bit, to make them work, but my Dremmel, & I can make it happen. ALSO, both of my new employees started work today. Perhaps tomorrow, or this weekend, I'll snap a few pics of the winch spools.

|

|

#83

|

|||

|

|||

|

60.95 hours this week, I LOVE it! Show me the $$$ ! Here's pics to accompany previous post

The new servo mounted winch drums  unnamed by Anthony Kalnoski, on Flickr unnamed by Anthony Kalnoski, on FlickrShowing the modifications done to them with the dremel tool  unnamed (1) by Anthony Kalnoski, on Flickr unnamed (1) by Anthony Kalnoski, on FlickrThe new crew members  unnamed (2) by Anthony Kalnoski, on Flickr unnamed (2) by Anthony Kalnoski, on FlickrThe newest candidate for RC conversion  unnamed (3) by Anthony Kalnoski, on Flickr unnamed (3) by Anthony Kalnoski, on Flickr

|

|

#84

|

|||

|

|||

|

The tracked loader was inexpensive from www.RuralKing.com . So inexpensive, that I bought two. Seems that I always mess up the first try, so this way I have the 2nd attempt already here.

|

|

#85

|

|||

|

|||

|

Nice haul skeet! Doing well on your projects. Love it mate!

|

|

#86

|

|||

|

|||

|

Soon as the wintertime slowdown gets here, I'll be getting going on the Bruder Mack conversion. I've already got the cab mounts made.....the ones that you came up with.

|

|

#87

|

|||

|

|||

|

Well.............Having today off I did a little tinkering in the shop. I got a little more done on the Bruder D5 conversion. I crafted this part to re-seal the unit. I had to cut a bit away to fit the drive servos in place. I DON'T want a bunch of mud/dirt/debris getting into it, so I came up with this. Shoe Goo holds it all together.

unnamed (6) by Anthony Kalnoski, on Flickr unnamed (6) by Anthony Kalnoski, on FlickrThe former shop foreman, here's his new home. He's installed into the seat with double sided stick tape. I DON'T want him to leave that cab, & have another tantrum. Doing so may run off the rest of the hired help.  unnamed (4) by Anthony Kalnoski, on Flickr unnamed (4) by Anthony Kalnoski, on FlickrHere's the inside of the dozer. I re-used the weight from the FAILED attempt I did before. Also The 3D YELLOW grill, is cut to accept a servo. I HOPE to use the servo to lift the blade. Right now the yellow grill is temporary, while fitting everything together. It's yellow because that's the filament that was loaded in the 3D printer at the time of printing it. Later, once I get everything exactly figured out, I'll re-print it in BLACK so it looks more like the 1:1. A big Thank-You goes out to NebraskaTrevor for the STL file of the D5 grill!  unnamed (7) by Anthony Kalnoski, on Flickr unnamed (7) by Anthony Kalnoski, on FlickrRemember those sanding blocks I printed a bit back? Well I thought they were too lengthy. So.....................I cut them in the miter box with the wood saw. I couldn't justify wasting ALL that time & material to throw them away, so I modified them POST print!  unnamed (5) by Anthony Kalnoski, on Flickr unnamed (5) by Anthony Kalnoski, on Flickr

Last edited by skeeter; 10-01-2017 at 02:53 AM. Reason: edited to issue credit where credit is due |

|

#88

|

|||

|

|||

|

With this style battery holder,

http://www.ebay.com/itm/2Pcs-Wired-C...30MrCHVOhee4yg If I attach a charger to it, can I charge the batteries while in the holder. I ask as I would like to keep the batteries inside the D5 Bruder conversion, rather then have to remove them to charge them. OR, if you guys have a better suggestion, I'm all ears. I already know I'll be placing a charge port on this thing. It's easier to open than stock, but will still be a PITA to open JUST to change/charge batteries. Last edited by skeeter; 10-01-2017 at 11:17 PM. Reason: typo |

|

#89

|

|||

|

|||

|

Today, after a short work day (Rare that they let us work on Sundays, as they DON'T want to pay the DOUBLE time

) I made a little more progress on the Bruder D5 conversion. ) I made a little more progress on the Bruder D5 conversion.  I DON'T have anymore HiTech servos like I used for the drive motors. They're on a SLOW boat from China. So.............I mocked up the blade lift with a Traxxas mini servo. I DON'T have anymore HiTech servos like I used for the drive motors. They're on a SLOW boat from China. So.............I mocked up the blade lift with a Traxxas mini servo.  unnamed (8) by Anthony Kalnoski, on Flickr unnamed (8) by Anthony Kalnoski, on FlickrI found an issue! I'll have to make a spacer to mount between the servo & the grill, to make clearance room. The linkage binds on it's self. I think if I add a spacer to push the servo into the grill farther, I can overcome this hurdle.  unnamed (9) by Anthony Kalnoski, on Flickr unnamed (9) by Anthony Kalnoski, on FlickrNow I have to await the rechargeable batteries, holders, & on-off switch to arrive on the fore mentioned SLOW boat. Once I get all these goodies, I'll hopefully have this model buttoned up within a few hours!  I intend to mount the On/Off switch at the rear of the operators compartment, behind the drivers LEFT hand side. I think there's a good opportunity to place it there, & have ease of access to route the wiring. Also it'll be easy to turn on & off there. I intend to mount the On/Off switch at the rear of the operators compartment, behind the drivers LEFT hand side. I think there's a good opportunity to place it there, & have ease of access to route the wiring. Also it'll be easy to turn on & off there.

Last edited by skeeter; 10-01-2017 at 11:21 PM. |

|

#90

|

|||

|

|||

|

Well...............Since work decided that I get to work graveyard shift tomorrow, I get to stay up all night re-adjusting my sleep schedule.

So..................I figured I'd start on the Leibherre wheeled loader. So..................I figured I'd start on the Leibherre wheeled loader.  I already have all the 3D parts printed for it, & everything I need on hand for it. I'd finish the D5, but I'm still awaiting the slow boat from China to bring the remaining arts for it. I already have all the 3D parts printed for it, & everything I need on hand for it. I'd finish the D5, but I'm still awaiting the slow boat from China to bring the remaining arts for it.  I'll be using the design Stein posted in his build thread, but with my own twist to it. Feeling that this loader needs a little more weight to it, I'll be adding weight to the tires. For now, I'll be adding half a pound to EACH wheel.  HOPEFULLY that will be enough? The weight will be epoxied in place to prevent lead exposure. HOPEFULLY I'll get a ways along with this conversion tonight. The lead is solid core 1/4 inch fishing weight. I unrolled it, measured it, & cut it in half. I DIDN'Tweight it. I figured as long as it's relatively close, it should be fine for hobby usage. HOPEFULLY that will be enough? The weight will be epoxied in place to prevent lead exposure. HOPEFULLY I'll get a ways along with this conversion tonight. The lead is solid core 1/4 inch fishing weight. I unrolled it, measured it, & cut it in half. I DIDN'Tweight it. I figured as long as it's relatively close, it should be fine for hobby usage.  a pic showing the before/after shots of the weighted wheels.  unnamed (11) by Anthony Kalnoski, on Flickr unnamed (11) by Anthony Kalnoski, on Flickr

|

|

#91

|

|||

|

|||

|

I've been thinking about the same thing! I've been prototyping with adding steel wire 4mm) inside the wheels, but your lead approach looks more doable. The handling will be much better with the added weight in the wheels.

Stein :-) |

|

#92

|

|||

|

|||

|

Well................I DIDN'T have all the stuff I thought I had. I had it all, but DIDN'T have enough of everything! The wheels I used ALL the epoxy that was suppose to do the WHOLE project, just to do the rear wheels. Even then, I fell short of materials. The 4mm Screws I have, AREN'T long enough to pass through the wheels, let alone the adapter plates. I did what I could, with what I had.

Each wheel took around 6 U.S. Ounces of epoxy to fill. I had planned for 3Oz. per wheel. I thought I had some more of it from a previous project. I DID, but it wasn't any good. It had hardened in the bottles, it was so old. Here's what I got done, with the supplies I had. One wheel is completed. The other still needs about 2Oz. more to finish.  unnamed (12) by Anthony Kalnoski, on Flickr unnamed (12) by Anthony Kalnoski, on FlickrI got the holes all drilled into the rear axle. I used blue Lock-tite on the mounting hubs to the motors. Pictures beside this is the lead I bought to use for the wheel weights. One spool does 2 wheels at a half a pound per wheel.  unnamed (14) by Anthony Kalnoski, on Flickr unnamed (14) by Anthony Kalnoski, on Flickr unnamed (13) by Anthony Kalnoski, on Flickr unnamed (13) by Anthony Kalnoski, on FlickrThe motors I intend to use are 12V 80RPM motors. They may be a bit fast for this project BUT..............they are what I have laying around. I figured I'd put them to use. Long story on how I ended up with 30 of them. I ordered them form Deal Extreme. I paid with PayPal. the website said my payment DIDN'T go through. I looked at the online bank statement, & it didn't show the PayPal transaction, 30 minutes after I made it. I re-sent the payment. The website STILL said it DIDN'T process. 30 minutes later, after STILL not seeing a PayPal transaction, I re-sent payment AGAIN. Once again, the website said the payment didn't process. At this point I gave up, & went to sleep for the night. the next morning, I awake to find 3 PayPal transactions had cleared. I also had 3 emails form Deal Extreme, stating that my order was processed. No worries, I thought, I'll get my 10 motors I ordered. Fast forward a few weeks, & I get home from work to find 3 packages from Deal Extreme awaiting me. :LOL: |

|

#93

|

|||

|

|||

|

Quote:

I'm glad I can do something that you find useful/helpful, since you've offered so much to others in the hobby! |

|

#94

|

|||

|

|||

|

Quote:

|

|

#95

|

||||

|

||||

|

Yes, you can hook up a charge port to a holder. I'd install a charge/run switch if your charge port doesnt have it built in.

I'd rather use 2/3A or Sub-C batteries instead of the AA that work with that holder. More capacity, higher charge and discharge rate, more flexabiliy in where the batteries go, can do a 6pack if your esc prefer it to the 4pack.

__________________

What do ya mean "Cars are neither Trucks or Construction"? It's still scale, and i play fairly well with others, most of the time... |

|

#96

|

|||

|

|||

|

Quote:

|

|

#97

|

|||

|

|||

|

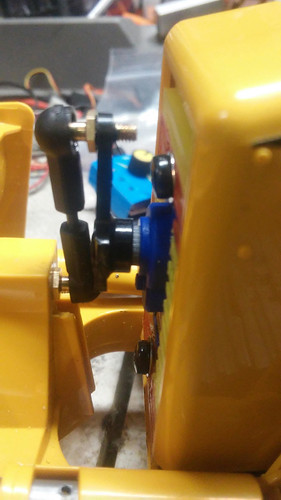

That SLOW boat from China arrived today. It brought my 4 new HS85MG Mighty Micro servo's. ONLY 3 are still in the boxes, as pictures here

unnamed (16) by Anthony Kalnoski, on Flickr unnamed (16) by Anthony Kalnoski, on FlickrThe 4th one has been opened to test fit into the D5 conversion. I'm pleased with how it fits so far. Since I hacked the grill to test the theory with a Traxxas servo, I'll be 3D printing another grill to test fit it with. I think I'll start the printer now, so the part's ready when I get home from work. Although I DON'T remember exactly where I saw pictures for the grill mounted blade servo, I know my success was limited with it. The set up kept opening the model due to the torque applied to the grill. Here's the idea I came up with to mount the blade servo, & solve this problem. That aluminum piece is bolted to the bottom of the dozer, & then I bolt the servo to it. The new part will take the torque abuse, rather then allowing the grill to work side to side eventually opening the model. The cut out in it was hand machined with my dremmel tool, the flexible extension, & a the cut-off wheel. The new grill isn't yet installed in this pic, but everything lines up properly when it's put together. That pic doesn't have any bolts in it for the servo,.......YET. It was just a quick mock up to give the idea how it would be when done.  unnamed (15) by Anthony Kalnoski, on Flickr unnamed (15) by Anthony Kalnoski, on Flickr

|

|

#98

|

||||

|

||||

|

2/3A battery.

https://www.maxamps.com/nimh-1600mah-2-3a-nimh-cell (2/3 length of an 'A' battery) You'll either have to pick up some solder and bars or wire to build the pack. Shoegoo or epoxy work to keep the pack rigid. I like the new servo mount, should be a lot stronger.

__________________

What do ya mean "Cars are neither Trucks or Construction"? It's still scale, and i play fairly well with others, most of the time... |

|

#99

|

|||

|

|||

|

Quote:

Yes, much stronger is the new mount. Once work FINALLY finishes for the day, I hope to get 'er buttoned up with that part of it. |

|

#100

|

|||

|

|||

|

Well...............after a grueling 17 hour day, I came home to take a nap! Ate dinner, & it's time to go to sleep so I can return tomorrow at 6 AM. I DIDN'T do anything today in the garage.

|

|

| Currently Active Users Viewing This Thread: 4 (0 members and 4 guests) | |

|

|