|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

|

Thread Tools | Display Modes |

|

|

|

#1

|

|||

|

|||

|

teeth look cool.

|

|

#2

|

|||

|

|||

|

I went with a straight cut, it's nice to have one like that as well.

Today I started to make a ditch and the tilt bucket worked great, no leaks! It's quite hard to run the tilt bucket, it's quite sensitive so you have to run low rpm and slow movements on the sticks and potentiometer that I run the bucket with. Need a little more practice with it, here is some pics, video later this week.

Last edited by Azonic; 07-06-2014 at 04:57 PM. |

|

#3

|

||||

|

||||

|

Looks great, like you could just climb into the seat and start digging!

|

|

#4

|

||||

|

||||

|

Nice pictures, looks REAL !!

Alan

__________________

To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#5

|

|||

|

|||

|

Quote:

Here is a new video from last weekend, a little to long maybe. http://youtu.be/tmH-eLi_-aA |

|

#6

|

|||

|

|||

|

I got myself a pair of 3D joysticks to control the hydraulic grading bucket a little better, its night and day from what I had erlier, I only got one wired up for now becuse I got no function for the other one yet.

http://youtu.be/hlISV8GfFtA?list=UUV...dzn82MA4zbNWaA |

|

#7

|

||||

|

||||

|

Nice setup!

|

|

#8

|

|||

|

|||

|

|

|

#9

|

|||

|

|||

|

Wow looks perfect!

|

|

#10

|

||||

|

||||

|

Nice details!

__________________

Emil G | MFZ Blocher Fendt 926 | RC4WD Volvo EC480 excavator | Carson LR 634 | Kenworth 6x6 hauler | Kenworth 6x6 dtrk My channel: To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. Construction site on Facebook: To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. Pictures on Instagram: To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#11

|

|||

|

|||

|

|

|

#12

|

|||

|

|||

|

Looking good...

Where did you get the 3d sticks? Cheers, Andrew P. |

|

#13

|

|||

|

|||

|

Both machines look awesome! Looking forward to seeing more.

|

|

#14

|

|||

|

|||

|

Thanks guys!

The 3D sticks I got from this site. http://www.robotshop.com/eu/en/3-axi...-w-button.html |

|

#15

|

|||

|

|||

|

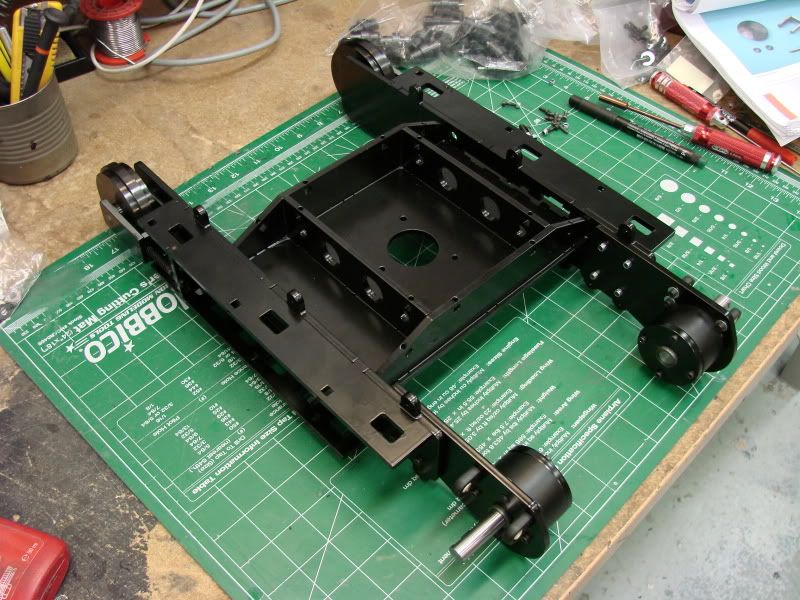

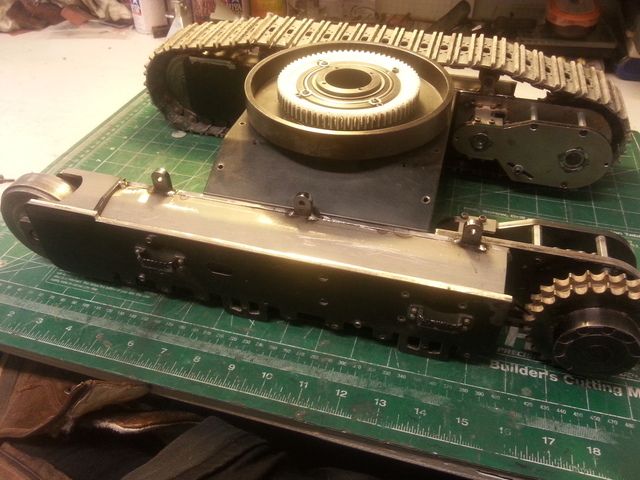

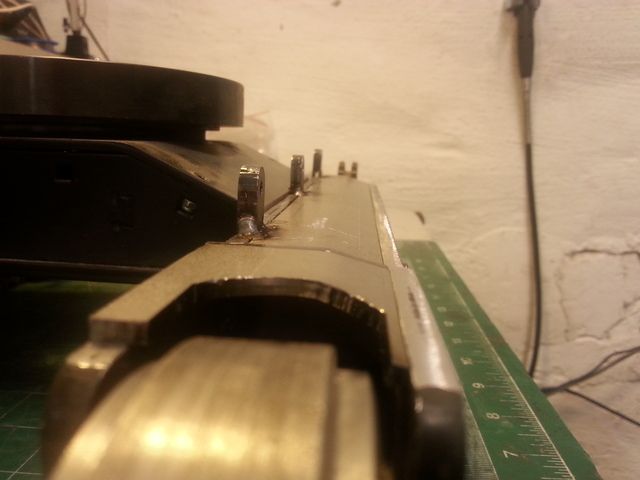

Well, winter is here, more time for hobby stuff for me, always fun!

I have modified the undercarrige a little on the 470, its a few things that have bugged me since the first time I used it outside. Its the holes under the top rollers, where all kind of debris gets in, and its not the place where you want sand, small rocks and stuff like that becuse thats where the drivemotor is and also the track tension mechanism, debris also gets down onto the lower rollers that way and locks them up sometimes. And I have to take this apart quite often to get rid of all the dirt that builds up in there to make everything running smoothly. So I started to make a sketch in Solidworks on how I could make it work, found a pretty good solution I think. Started to cut up the steelplate with the holes in it, removing 5mm from the outer plate to get an angle on the new topplate so that dirt rather falls off the undercarrige then just load up. Got the new steel from my laser cut man and started to spot weld everything together today, turned out pretty good I think, its more to scale and should keep dirt out of moving parts! Here is some pics of the progress... Here you can see the square holes im talking about.      Here is with the new parts mounted.

|

|

#16

|

||||

|

||||

|

Nifty alteration Kalle, hope it cures your ales with the rocky areas you dig in.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#17

|

|||

|

|||

|

Quote:

|

|

#18

|

|||

|

|||

|

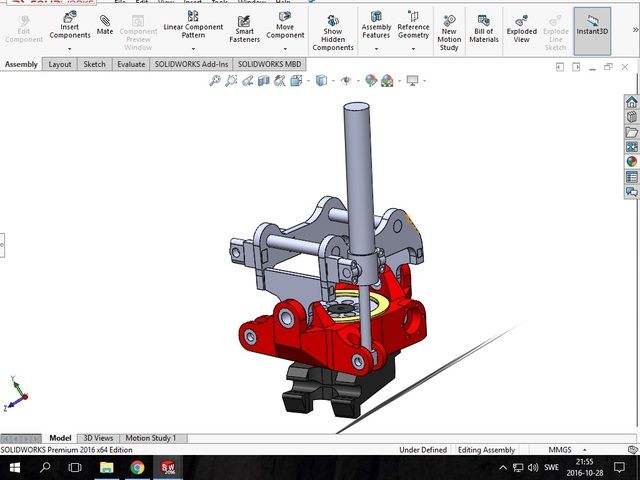

Not much digging with the 470 lately, now fall is here and winter is coming, so I have started a little attachment project.

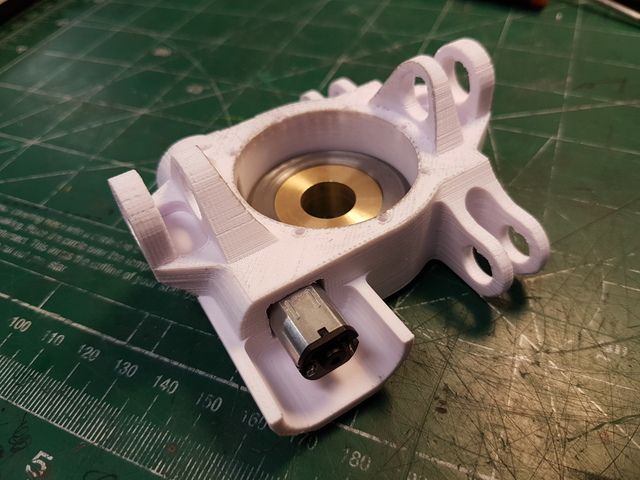

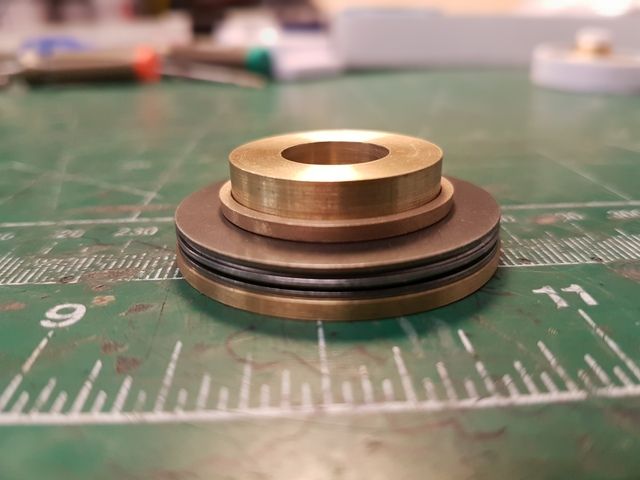

Its a rotortilt, very common here in Sweden and the nordic countries around. So I started in Solidworks to sketch it up, I have only used SW for about a year, so im no professional. I have printed a prototype in my 3D printer and it seems to work out pretty good, motor I have for rotation right now is a bit slow but will probably change that later. The tilting action will be hydraulic. It will also feature a remote controlled quick coupler for easy attatchment changes. If it works good I will send the files to a cnc guy to mill them out for me, the lower part will be made from steel and the part above from aluminum. Here are a few pics.           https://youtu.be/XGlGnTYUExU |

|

#19

|

|||

|

|||

|

Nice drawing, good to check out dimensions with printing before adding a lot of cost CNC milling the parts.

|

|

#20

|

|||

|

|||

|

Quote:

Exactly, great for prototyping, but can be made really strong as well, but plastic is plastic, I prefer metal for strength and realism.

|

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|