|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

|

Thread Tools | Display Modes |

|

#1

|

|||

|

|||

|

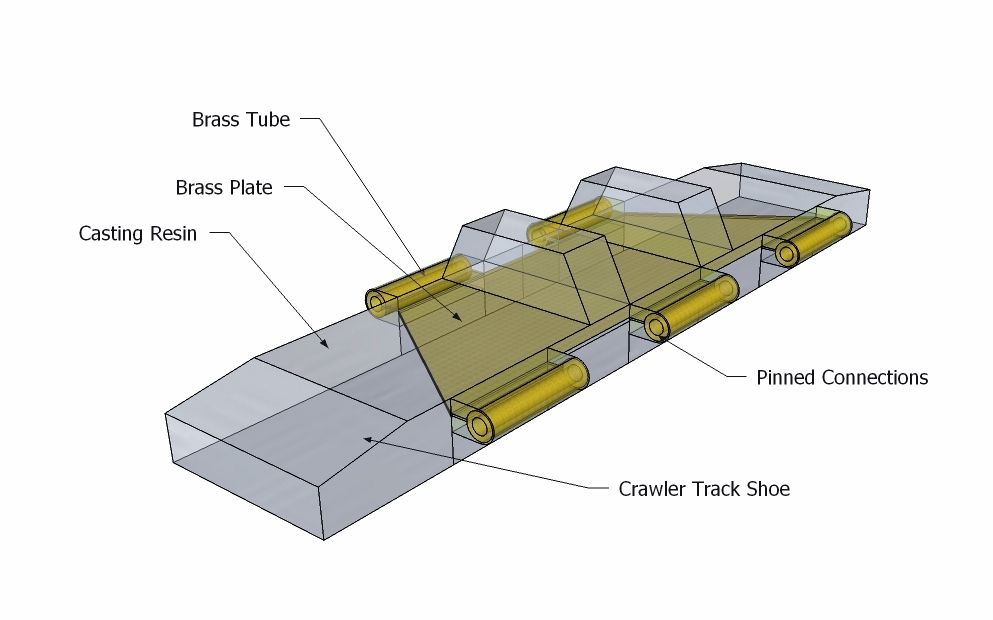

Is this a reasonable way to design a crawler track tumbler for a scale model? Is cast-able resins strong enough to make this part? 3D printing? Any ideas will be appreciated. I did order a track shoe that is 3D printed and a few boom parts. I am hoping they will make good master patterns for casting resin. The only thing better than first hand experience is someone who has already experienced it.

|

|

#2

|

|||

|

|||

|

I'm sure the tumbler would work but I think your cross bars should be bigger and the lugs on the pads smaller if required. What connects the pads to one another? Welcome to the forum and I'm always glad to see someone building a crawler crane.

|

|

#3

|

||||

|

||||

|

Seems like a good enough plan to start and see how it goes. Tom will likely chime in on this one, he cast the pads for his shovel and it works great.

I know from my aluminum pads experience that the hinge points need to be nearly perfect so you don't get a twist or a left or right bow in them when they are pinned together. This will cause alignment issues and they will catch or try to work off to one side of the tumblers. Jim |

|

#4

|

|||

|

|||

|

Pricer-this is a unique idea for tumblers but I don't think it would work cast from resin because of the size of your round bars. They probably would break. I cast some track pads from epoxy resin mixed with a hi-density filler and it worked great. A cast tumbler might work if you re-design. Maybe use a double tumbler but make two separate drive dogs where each one would engage a tumbler. Just my opinion. Jim made an important point about the hinges. You learn a lot after you try something and that makes it all worthwhile.

|

|

#5

|

|||

|

|||

|

Thanks guy's for the welcome and the advice. I have been thinking about how to put a metal insert into a casting mold to help make the part more durable yet retain the details that casting can offer.

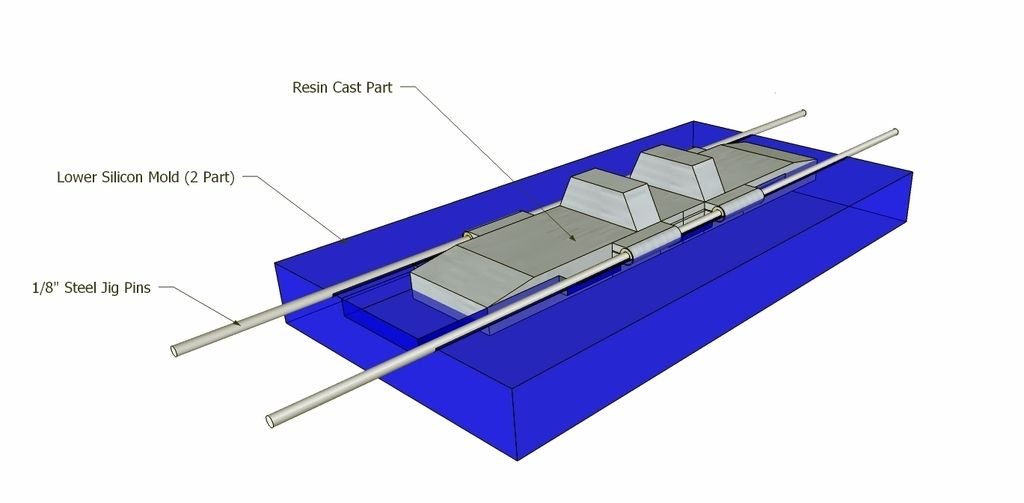

I did get my crawler track shoe in from the 3-D printer to discover I basically drew the part upside down....... LOL. So I made the corrections and will order two tracks in order to make sure they work well together before making the silicon mold. I am not familiar with any additives to put in the resin to make it stronger. Any direction with that would certainly be appreciated at this stage of it all. I think I will add metal pins to the silicon mold that can be removed once the part has solidified. This may keep me from having to drill out the holes for the pins I am thinking. I had even thought about brazing a solid brass wire to 1/8" brass tubing and using the steel pins in the mold to hold them in alignment to set into the mold prior to casting the part. The double tumbler/dogs sounds like an excellent idea! I am wondering if that could work on a cast tumbler as well. It would make the part stronger I think but I am not sure. De-lamination of the materials could be possible but if a center hub made from metal could be used in the casing jig/mold I think adding other solid wire structures that extend from the hub outward to the edges of the tumble could be useful if it would work. I am going to try the idea of the track parts as well as the boom connectors and see where the idea leads me. The biggest fun of all of this to me is in figuring it out. The ends results are fun to see, but I am afraid I would want to begin a new project at that point and in short order too. Thanks again for all of the responses. I will try to get some pictures posted of some of my projects very soon. I have made various parts for an American HC230, American 11320 and one crawler track side frame for a Manitowoc 21000 as well as some test pieces for experimentation. |

|

#6

|

|||

|

|||

|

|

|

#7

|

|||

|

|||

|

I too am making a crawler crane a Manitowoc 18000 here on the forum i started milling the crawlers from alum. after i finished designing them but i am manual milling so its a slow going process

__________________

Steve |

|

#8

|

|||

|

|||

|

Quote:

I have been working on drawings for the Manitowoc MLC650 for almost a year now. I built a few test hoist (Boom Hoist) with some success. Right now I am focused on the 11320 and the HC230 American's. Best of luck to you in your build and I look forward to keeping an eye on your progress. Looking good so far. What scale are you building the 18000 in? |

|

#9

|

|||

|

|||

|

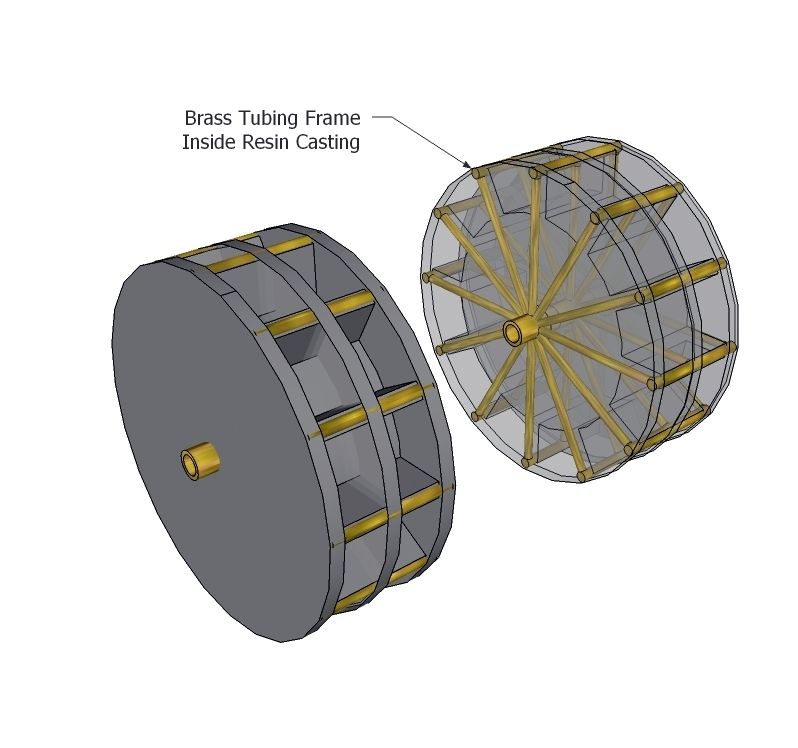

Here is a picture of the idea I had for resin casting over a brass structure. I tried posting it yesterday but for some reason it didn't work. Here is another try. |

|

#10

|

|||

|

|||

|

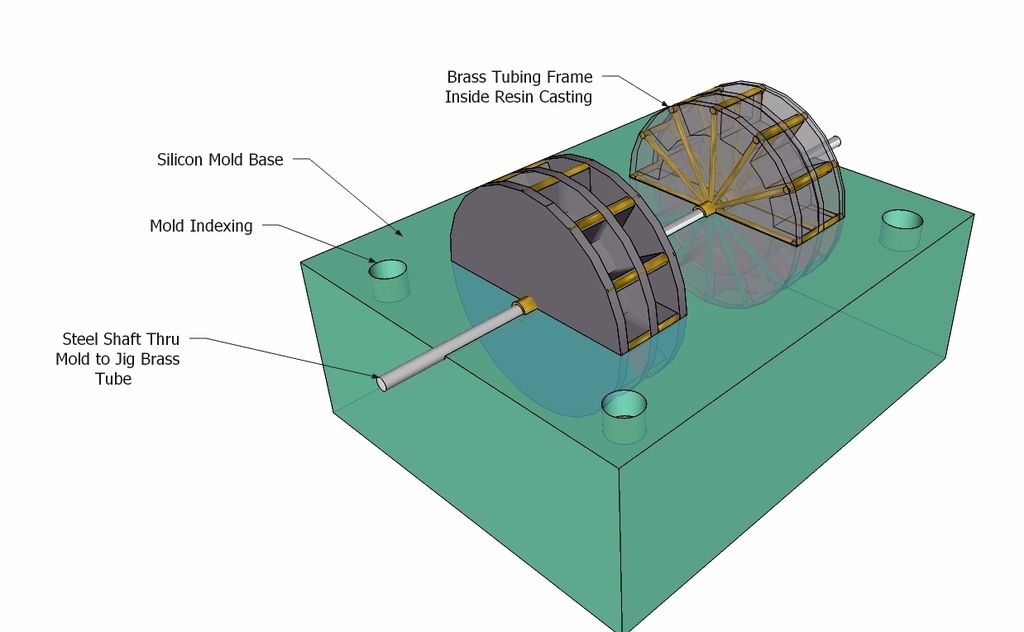

Here is a drawing of the resin/Brass structure jig in the bottom part of a two part mold. I am still waiting on 3D parts to be shipped to be used as mold masters. If anyone has any ideas or experience with this I would appreciate any advice I can get prior to getting started. Thanks |

|

#11

|

|||

|

|||

|

Resin Casting over brass tubing frame idea. 3D print a master pattern of the finished tumbler, make silicon mold of master, build brass tube frame, jig the brass tube frame in the silicon mold, add casting resin to mold, remove finished part. Additional part details could be added to the 3D printed part (i.e. Bolts, curved openings, letter, numbers.) to bring the part to life. Just an idea, one of which I am working towards. |

|

#12

|

|||

|

|||

|

Part shown in the De-molding stage for illustration. |

|

#13

|

|||

|

|||

|

My 18000 is going to be in 1/16 i used a scale conversion to get all the measurement ratio and i will definitely be watching this build as well and as far as the guys on the site they are all very helpful, talented and a wealth of knowledge all around you.

__________________

Steve |

|

#14

|

|||

|

|||

|

Pricer-I cannot see the pictures you have posted. You may need to use Photobucket. It is a free hosting site. Here is a filler that will do the job for you when casting parts-

http://www.jamestowndistributors.com...34&nobot_crawl I don't know where you are located but there are a lot of west systems dealers around the country. I would also suggest using the west systems epoxy. It is good stuff. The more filler you use the stronger the part will be but it needs to be thin enough to pour freely into the molds. You may have to experiment to get the correct resin to filler ratio. |

|

#15

|

|||

|

|||

|

I will look into the photo bucket. Can you see the pics I have attached? I think there are a few boat supply businesses in my area that sell West Systems. Is West Systems stronger than Alumilite? I am at the beginning of the learning curve when it comes to casting. I did purchase an Alumilite Casting Kit.

|

|

#16

|

|||

|

|||

|

|

#17

|

|||

|

|||

Can you see theses? From Photobucket |

|

#18

|

||||

|

||||

|

Yes!

|

|

#19

|

|||

|

|||

|

Pricer-starting at post #16 I can see the pictures but nothing before that. I am not familiar with alumilite. I am not understanding the mold you have pictured. That is a very complex part. Can you make that model to mold from? That will not be a simple pour mold. The way that is pictured I think it will have to be some type of injection molding.

|

|

#20

|

|||

|

|||

|

Quote:

The master part to make the mold would most likely, in my case, be 3D printed. The 3D printed part would be a representation of the finished part of coarse and when the mold is ready for casting, the brass structure will be inserted in the mold on a steel shaft and spaced evenly before attempting to cast any resin. I have watched a few video's that Alumilite has made regarding making various parts with two part molds which also included molding around threaded metal parts which were unfastened after the resin had cured leaving a threaded hole. It also showed how to cast around a hex nut which would be in bedded in the cast part. The bolt actually is sticking through the side of the mold prior to casting the part. I have also seen a video that shows how to make several holes in the mold to let air escape when pouring a complex part. In the case of my crawler shoe, casting it around the actual pin I will use in my model, it gives me a good alignment and hole size right out of the mold ( in theory that is....lol) I may be totally off track hear with all of this but I believe it is worth a few try's before throwing in the towel. (I have a box full of those towels too). I also saw a video of someone who made a production mold for fishing lures and they also used an injection method. Basically what I saw was that they used a large syringe to force the resin through the mold. Any thoughts and input concerning any of this will be greatly appreciated. I have not ordered my 3D printed tumbler yet. I am still working out my plans in CAD and 3D drawings before I spend the money. Thanks |

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|