|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

|

Thread Tools | Display Modes |

|

#1

|

|||

|

|||

|

Well I have jump in with my plan to build a scaled version of the Koehring 305 Dragline. My father owed two of these during my years at home so "we" have a history. I built the attached drum today, flexing my machining memory....not too happy with it, but this process will take some trial and error for sure!!

To those of you who have fabricated/machined miniature drums before, please suggest away!! I used 1" Sch. 40 pipe for the barrel, and flame cut 1/4" plate for the drum flanges. The drums will have roller bearings on a shaft, fixed on both ends to a draw works frame. |

|

#2

|

||||

|

||||

|

Great!!!!!

Looking forward to following progress on this project! Kerst |

|

#3

|

||||

|

||||

|

Is that pipe thread? If so, you may want to try to remove the sharp "V" with a round file so the wire rope will not get frayed. Interesting idea using tapered pipe thread because on some of the 1:1 machines the hoist laggin is tapered so the ropes feet per minute increases as the hoist goes up .

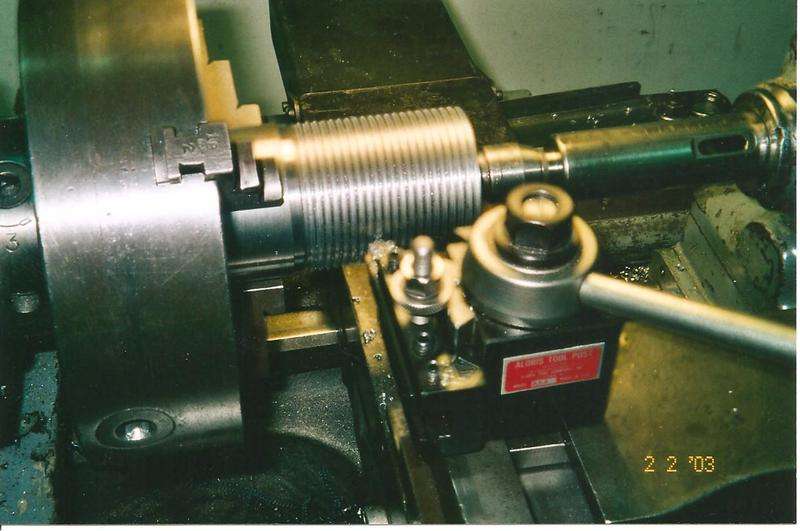

Referring to my dragline; I have both LH and RH threads that I cut with a tool that I ground to a radius to conform to the wire rope. I figured out how many wraps ( threads per inch with room between) around the circumference I would need with a couple extra to have enough to hoist and drag in without any overlaps or running the hoist line off the drum. There actually wasn't too much figuring because I was building to the exact pitch diameters (in scale) as the 1:1 machine. Hoist Laggin being cut on my lathe

|

|

#4

|

||||

|

||||

|

Looks good. Im building a yarder right now and plan to run 7 various drums and will have questions like yours as well.

__________________

Jarrett |

|

#5

|

|||

|

|||

|

I think the drum barrel area will either need less weld or I might bore out the flanges and well the barrel from the outside of the flange....definitely need less weld metal to machine lagging grooves in for sure. I need the thickness of the flanges in the barrel bore area to hold the ball bearings...I really don't want to machine bearing carriers. Like I said, my machining skills are rusty, and they weren't all that great to begin with!! This is going to be a fun project.

9W, no these are not pipe threads, just a poor job of spindle speed vs thread speed! Incidentally, nice job on your barrel machining....I think I'll copy your grooves with a more rounded lathe tool and increase the pitch to accommodate larger rope...and slow down my spindle speed for sure!! You will see smaller to larger diameter drum sizing in many shovel applications...the small diameter is utilized at the initial beginning of the dig cycle to help the machines break out force then increasing line speed to increase the machines cycle speed(according to a Koehring serviceman who helped us with a warranty repair/replacement service call) Thanks |

|

#6

|

|||

|

|||

|

Yay! Another cable machine! How are you driving the drums?

|

|

#7

|

|||

|

|||

|

My plans are to use two modified servos, via pinions and a bull gear arrangement from one of my helicopters, for each drum. I have a bunch of servo's, gears, pinions, bearings, shafts from my rc helicopters from which to choose. If my planning is correct I should be able to replicate the line speed and swing speed close to the real thing. One servo per drum would work but "when in doubt, go **** for stout".

|

|

#8

|

||||

|

||||

|

Quote:

Thank you explaining the tapered drum better. I left that part out about smaller diameter giving more power for breakout force. I can't remember what TPI I used to cut the laggins on my machine. Do you have a prts book for your 305? I think I saw one on ebay yesterday |

|

#9

|

|||

|

|||

|

I probably bought the parts book you saw! It was pricy but really helps to scale components from for sure. I also bought a sales brochure from that era that has some great pictures to help me.

|

|

#10

|

||||

|

||||

|

Bartles, If you can't find the picture on my thread, Here is the one you wanted to see on how I attached the flanges to my hoist drum.

|

|

#11

|

|||

|

|||

|

Nice work indeed...I am about finished with the drag drum. I am using cold roll and machining it as a one piece part. This Chinese lathe I have is a little loose to say the least, so I think I better approach all the machining work in one set up. I have a lot of filing to do on the cable grooves!

You do nice work sir! |

|

#12

|

|||

|

|||

|

Well I have made some progress.......the servo speed is a little slow but I plan to increase the system voltage to gain another 20%...the line pull is very strong.

Comments and suggestions are most welcomed!!

|

|

#13

|

|||

|

|||

|

Looks good. I like your method of adapting a shaft to a servo. Will have to keep that in mind for future reference.

|

|

#14

|

|||

|

|||

|

Just finished fitting up the upper turntable rollers...

|

|

#15

|

||||

|

||||

|

Hello bartles, i'm a great fan of cable excavators, your parts looks very good. But i think you should not start each time a new thread.

__________________

Best Regards Wolfgang To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#16

|

|||

|

|||

|

....pardon my question, but I must admit I am not familiar with all the in's and out's of the forum...so I just keep adding to my original post?

|

|

#17

|

||||

|

||||

|

Looks to be heavyduty ,nice metal work

__________________

To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#18

|

||||

|

||||

|

Quote:

Cheers, Neil. |

|

#19

|

|||

|

|||

|

Thanks, it will be heavy........the tracks will be a challenge!

|

|

#20

|

|||

|

|||

|

thanks

|

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

| Thread Tools | |

| Display Modes | |

|

|