|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

|

Thread Tools | Display Modes |

|

#61

|

||||

|

||||

|

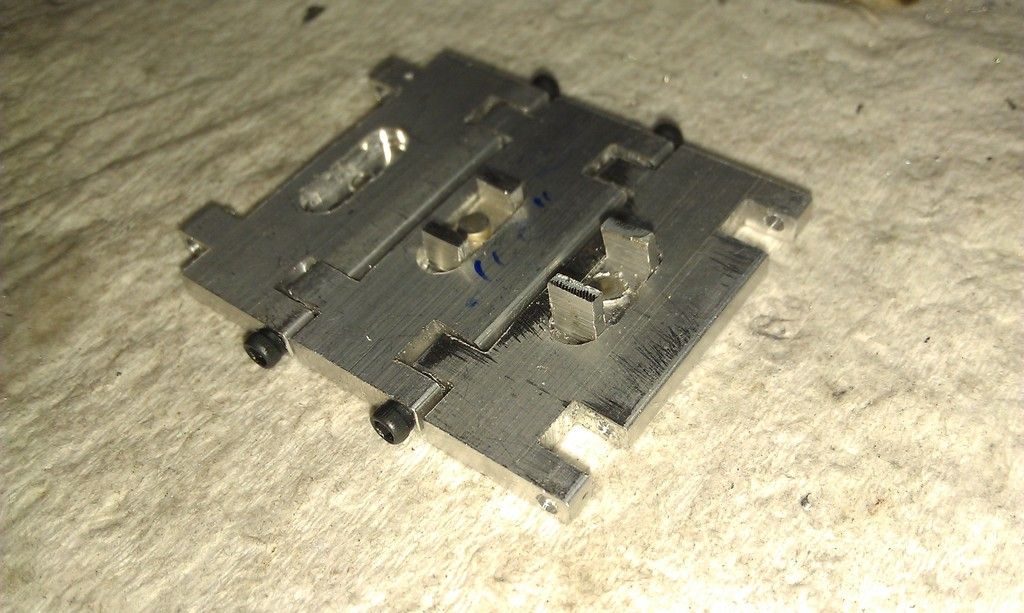

Not too much "visible" progress today but I have actually gotten a bunch done. I wasn't happy with the brass pins linking the pads so I decided to try taping 2-56 holes in the outside tabs and drilled a clearance hole on the inside tabs. The only 2-56 screws I had are shown in the picture. They don't look too bad although a bit big looking I think. I ordered some button head and some plain set screws. I will try those and decide which way to go.

If I had made this decision earlier i think I would have milled the pads such that there was a shoulder in the outside to let the head of the screw sit flush with the outside edge of the pad. Jim |

|

#62

|

||||

|

||||

|

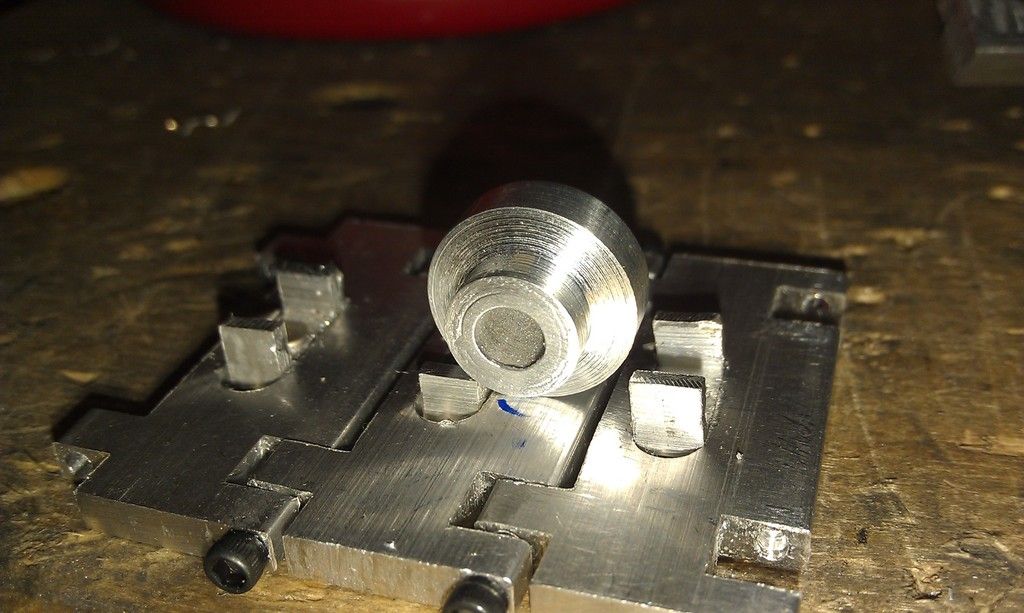

How would you make these idler rollers?

I need to make 12 of them. I am starting with 3/4" round aluminum stock. They have a taper to help clear the drive dog tabs on the pads. This is one of those things that I look at and think " that shouldn't be too hard", and then when I start making them I end up with two or three and NONE of them are the same. I had been trying to make the taper using the side angle on my right hand turning tool bit, but that is problematic when it comes to doing the second (or left hand side if the part stays chucked up for the entire process, which I think it should). So, now it finally dawned on me, use the compound to make the taper. My problems are: Keeping concentricity. (I think I solved this by NOT over drilling the center hole, so that when I pull the stock out, I don't start off on the next part with an off center hole.) Getting the same length on the shoulders on each side. Getting the center rib in the center. I am using my dial indicator on a mag base to move the carriage in as I turn the shoulder. Should I be doing this with the part chucked once for the entire part? If so, should I be using a left hand turning tool for the left hand shoulder and Turing away from the chuck? I think this all comes back to one of my very first questions when I got started with the lathe, "how do you know what steps and what order and how to decide what tool or procedure"? Thanks for any tips or suggestions. Jim |

|

#63

|

||||

|

||||

|

Keep the bar chucked through the whole process. Leave enough bar sticking out of the chuck so your tools can do what is needed for say,2 or 4 rollers. Turn the OD , do the step and taper using LH and RH tools, center drill, rough drill, ream to size you need, part off the finished roller making sure the left and right are equal so rib is centered. Now this process will keep everything concentric but don't drill too far because when you have to pull the bar out of the chuck to machine more you will have to face the bar off so it's clean to start another center drill.

|

|

#64

|

|||

|

|||

|

I sorta have the same issue, but am thinking of taking the easy out and uesing some 5mm bearings instead of making lots of rollers as they will sit nicely in my K1 track.

By the way progerss so far is looking realy good. cheers andy |

|

#65

|

|||

|

|||

|

Jim-I think everyone would agree on this. Practice is the best tool. Get to know your machine, find out the problem areas and learn how to work around them. You are doing great so far. Keep working and enjoy!!

|

|

#66

|

||||

|

||||

|

Thanks guys! I think I am going to start working on a drive tumbler while I wait on my 2-56 hardware to arrive. I figure if the diameter of the tumblers change so will the idler rollers so better wait on them until I know I have a tumbler that fits the pad links.

Jim |

|

#67

|

||||

|

||||

|

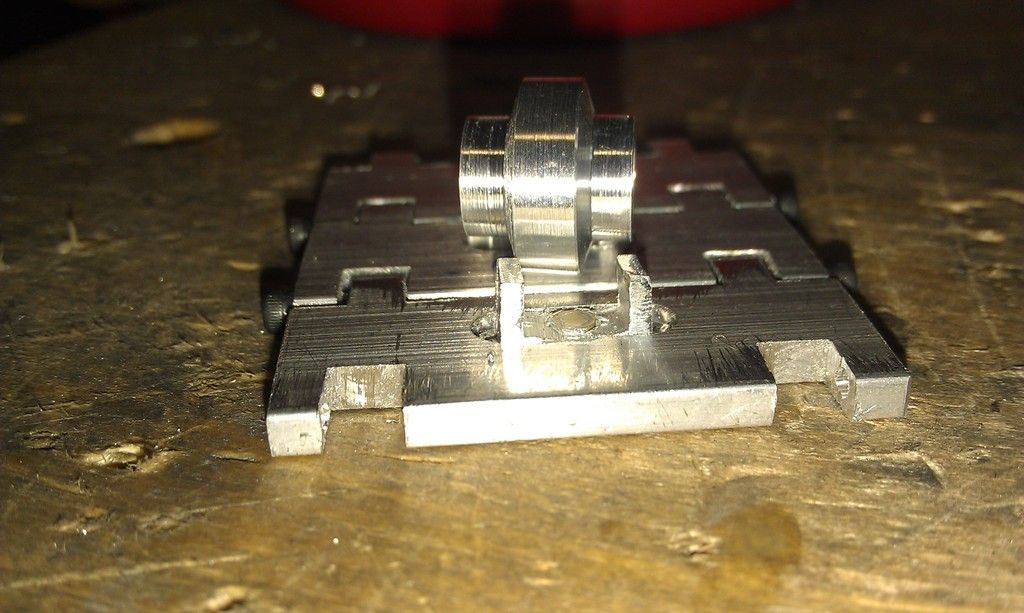

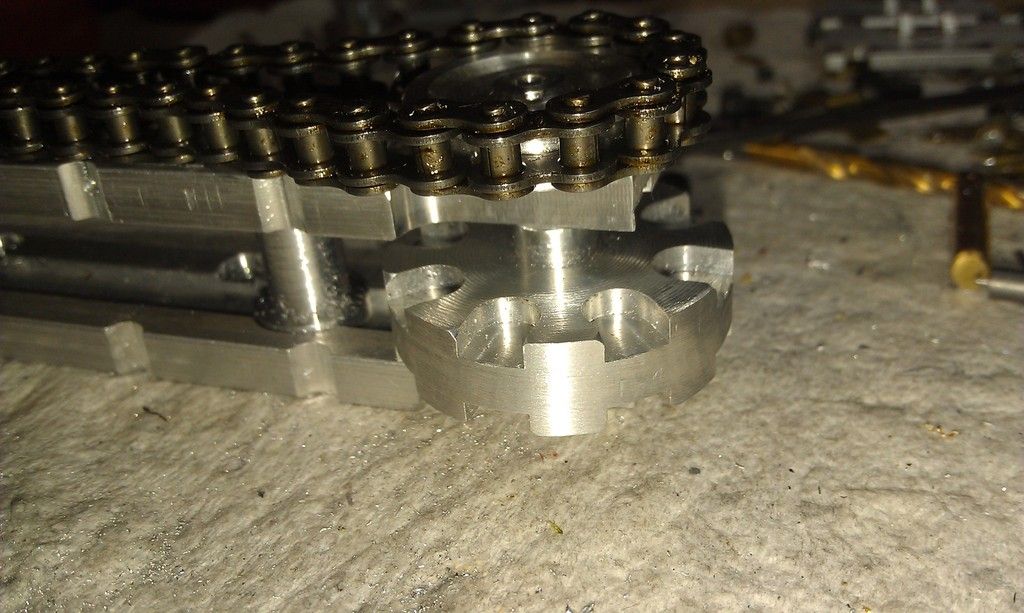

And now, for something completely different...

Here is my first prototype drive tumbler! Still working out the details.  Don't even have the second side formed because I didn't leave enough center hub to hold onto. Back to the lathe... Jim Last edited by Rvjimd; 06-14-2015 at 12:53 PM. Reason: More |

|

#68

|

||||

|

||||

|

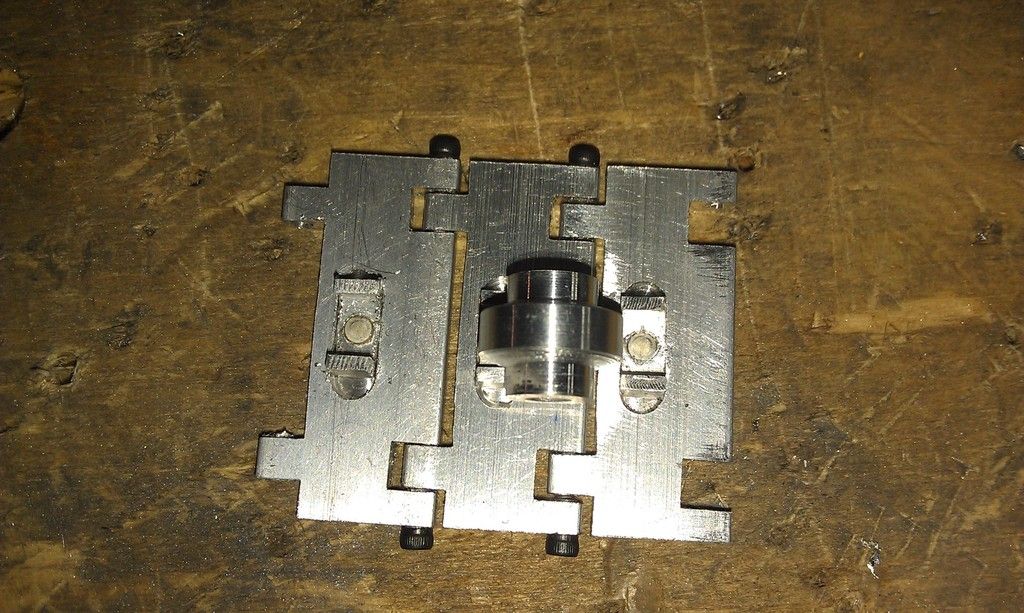

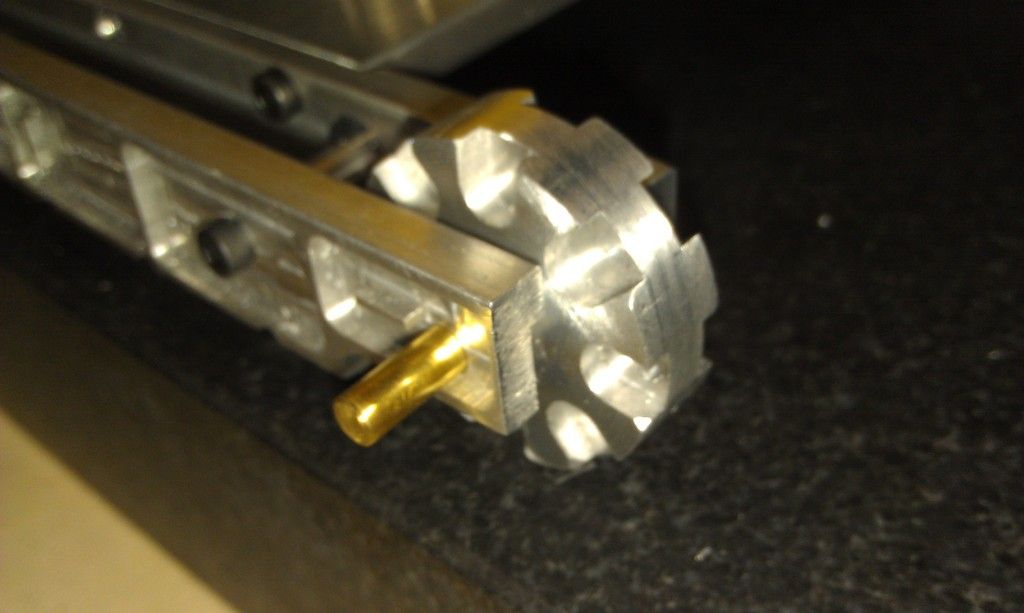

Finally got one tumbler done both sides. I am waiting on hardware so I can assemble an entire unit. Need to have it nearly complete so I can tell what I need to do to the drive dog ears on the pads and the tumbler flanges.

I am pretty sure I am going to need to put a bevel on both, just not sure how much on each. I sure it will be more trial and lots of errors.  Jim |

|

#69

|

||||

|

||||

|

Hi Jim, brilliant how you learn as you go and sort out the problems as they come. Learning a lot just reading about your trial and errors. Many thanks for documenting the process.

Cheers! Stephan

__________________

Cheers, Stephan (Rakthi is the one in the avatar) |

|

#70

|

||||

|

||||

|

I am planning to drive the crawler with chain and sprockets like a full scale. I am thinking about ordering some of this .1227" plastic chain but it says 14lbs tensile strength. Is that is way to weak! I don't have a good feel for that in this application.

https://www.servocity.com/html/plast...l#.VX7XXXA8KrU Is it okay to post a link like this or is that a no-no? I already have some .25 inch stuff, but I haven't found sprockets small enough yet. I'm gona need about 7/8" for the large sprocket at the tumbler and something smaller at the motor. Stephan, I get a bit out of the process too. The other day I was about to make some more little tabs that rivet into the pads. I was starting to clamp them into the mill vise and remembered that I had that little fixture block. I went to my thread just to recall the size and shape of the block to make it easier to find in my pile of stuff! Jim Last edited by Rvjimd; 06-15-2015 at 09:57 AM. Reason: More... |

|

#71

|

||||

|

||||

|

Jim,

Check this out and see if its what your looking for: http://www.mcmaster.com/#miniature-roller-chain/=xmuspu |

|

#72

|

|||

|

|||

|

Jim-your thinking is right on with this. The dia. of the tumbler dictates the size of all the other parts. You may have some work to do on the tumblers but I think you are on top of that. Personally, I would go with the metal chain but finding the really small sprockets may be a challenge. Does the 1/4" chain look too big? You might find something smaller in some clock works sites-not sure. Keep the pictures coming.

|

|

#73

|

||||

|

||||

|

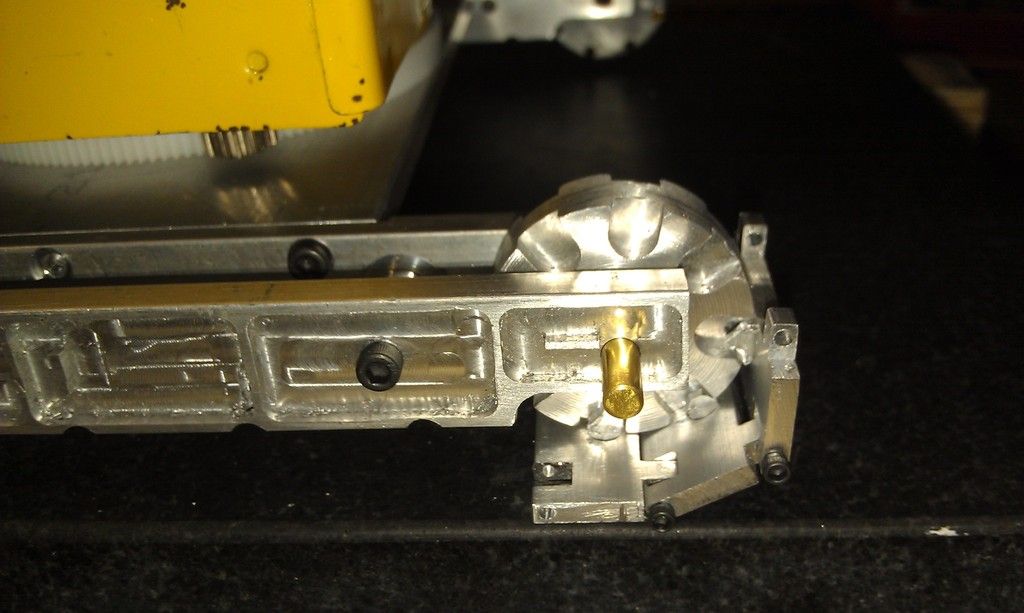

Truck maker, thanks for the link. I always forget about McM for parts. I just seem to get stuff other places.

Tom, the .25 looks okay. Maybe just a bit big but not too bad. The common 10T sprocket would even look okay next to the tumbler but I might have to search for a smaller one on the motor.   The little pulley I have in the photo is about the size of the smallest sprocket I have found so far. Jim |

|

#74

|

|||

|

|||

|

Jim-if the 10-t sprocket is okay for size then maybe you could use the same on the motor. When you get a little farther along you can turn the assembly and calculate the speed you need and get a motor that speed. If you get a slow motor it should have a lot of power. Just a thought- keep at it!!

|

|

#75

|

||||

|

||||

|

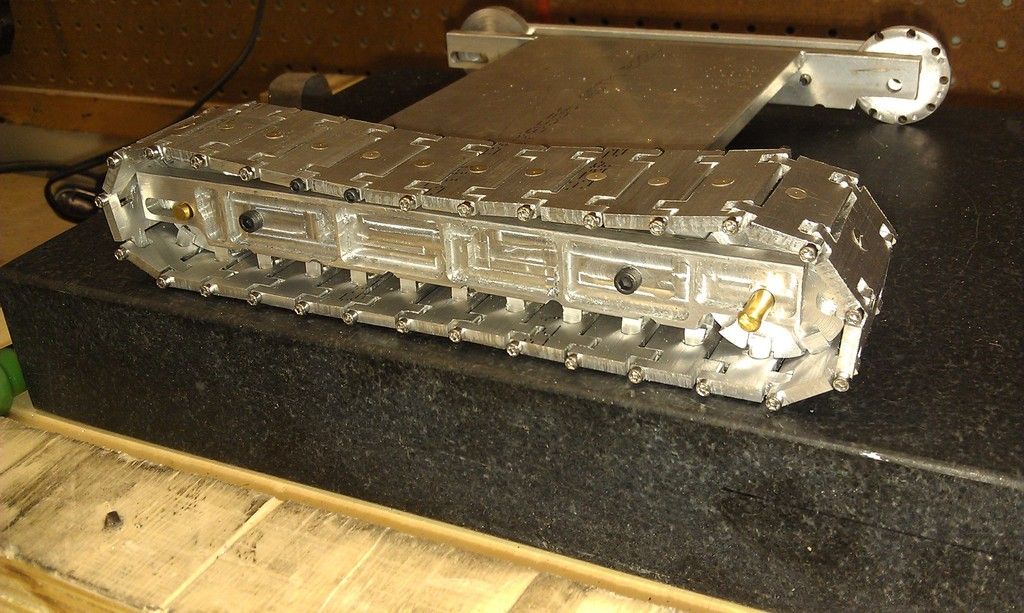

Decided to bolt up both sides again so I took a few more shots.

Shaft coming out the wrong side here, but no problem yet...    Jim |

|

#76

|

||||

|

||||

|

Slip ring? Has anyone tried a DIY slip ring? I have repaired one on a in motion servo satellite reciever and I am thinking about trying it. I guess I haven't looked online yet to see how much they are and how it would fit into the UC?

One of the things with my particular install is that there "should be" a 1/4" shaft in the center of the bed that the upper house centers and pivots on. This way it matches the truck frame, in case I want to switch back to the highway truck chassis. Jim Last edited by Rvjimd; 06-15-2015 at 04:36 PM. |

|

#77

|

||||

|

||||

|

Look for some # 25 chain, http://www.amazon.com/Koch-7425100-R.../dp/B004HKITHA Just saw a refence, that scooters use it. http://www.electricscooterparts.com/chain25.html I have a 9 tooth sprocket for a project, can't remember where I bought it 25 years ago. http://www.surpluscenter.com/Power-T...1-2742-9-A.axd

Cheers, Neil. |

|

#78

|

||||

|

||||

|

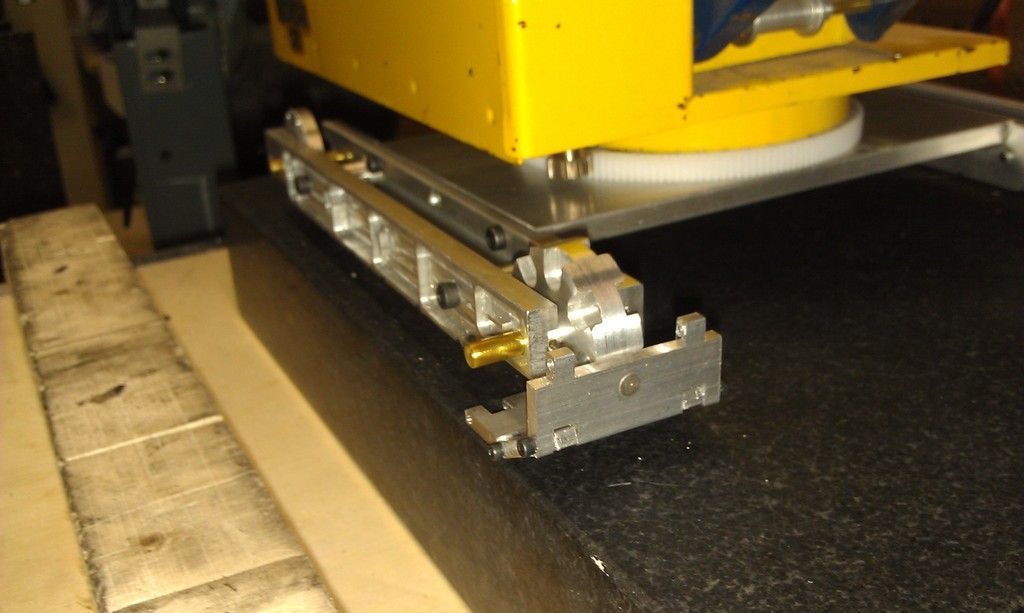

I got some of my Enco order today and it had some of the 2-56 screws I was waiting on. I think I can shape the ears on the pads and get smooth operation.

Jim |

|

#79

|

|||

|

|||

|

Those tracks are so cool! I like that old iron

__________________

Life: it's all about the ride! |

|

#80

|

|||

|

|||

|

Jim- isn't it nice to see all that work finally shape into something. Looks good, although that 2nd picture with the close up of the tumbler is confusing to me. The pitch looks good except on 1-pad. That I don't understand. I think all you can do is finish the pads and see if it turns. Hope it works for you!!

|

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|