|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

|

Thread Tools | Display Modes |

|

#21

|

|||

|

|||

|

Quote:

|

|

#22

|

|||

|

|||

|

Jim-you have the right approach. I made sample pcs. from anything I could find that was soft. Actually delrin works great. It machines good and is easy on your tooling. I made my final sprockets from delrin and they should last forever.

|

|

#23

|

||||

|

||||

|

Yea, I have some white, but black would look pretty good as well...

Thanks Jim |

|

#24

|

||||

|

||||

|

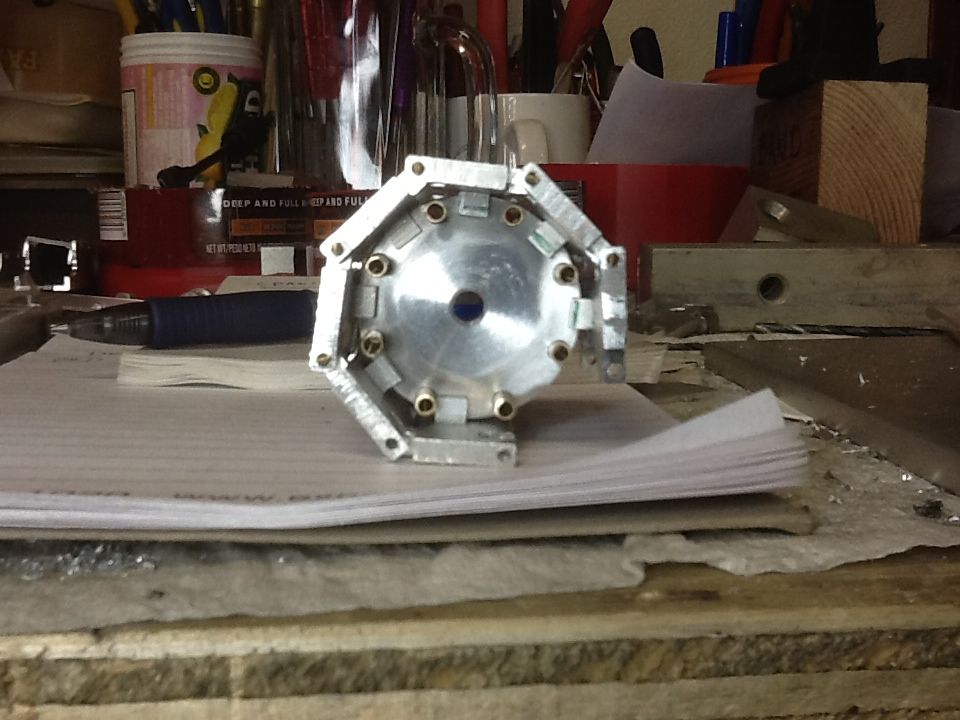

I think I got it. I think part of my trouble was understanding the darn DRO and bolt circle function. I made a new tumbler blank the same diameter and put one EXTRA hole (10 holes) on the first sample and that was obviously not right. My first one had 9 holes and it was close but not quite correct. So, I flipped it over and tried 8 holes, which is what I thought I was going to try the very first time, not sure what I was thinking then?

Anyway, 8 looks pretty good. I'm going to move on to making the side frames and see if I can get a motor mounted to an axel shaft and then I will really be able to see if it is close enough.  Jim |

|

#25

|

|||

|

|||

|

Jim,

It looks like all the pressure is only going to apply to one cog at a time. Shouldn't it apply to all the cogs evenly, same as a track chain on a dozer? Just a suggestion

__________________

Life: it's all about the ride! |

|

#26

|

||||

|

||||

|

I think in the last photo the bottom pad is loose allowing slop at that drive dog. When I hold them snug they all impact pretty good. I plan on some sort of spring tension system on the idlers.

Jim |

|

#27

|

||||

|

||||

|

Quote:

Looks like you have it figured now anyway Jim! |

|

#28

|

|||

|

|||

|

Good to see your getting it all working. Looking forward to seeing the rest of this build

__________________

Life: it's all about the ride! |

|

#29

|

|||

|

|||

|

https://m.youtube.com/watch?v=2lPNqn8LU4Q Found a very informative series of videos on gear cutting, thought I would share. This is what I watch instead of prime time tv.

__________________

Life: it's all about the ride! |

|

#30

|

||||

|

||||

|

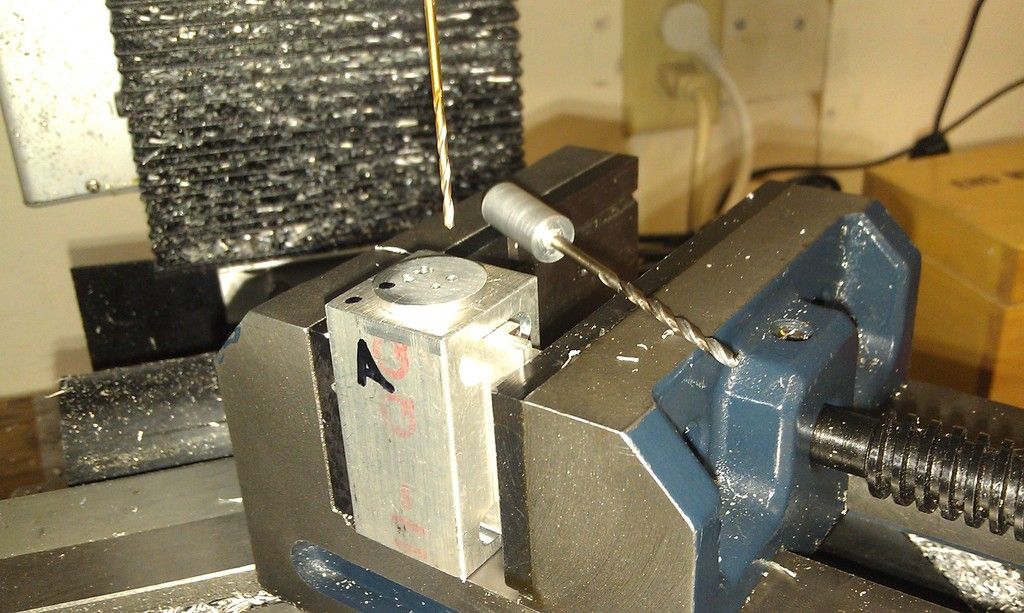

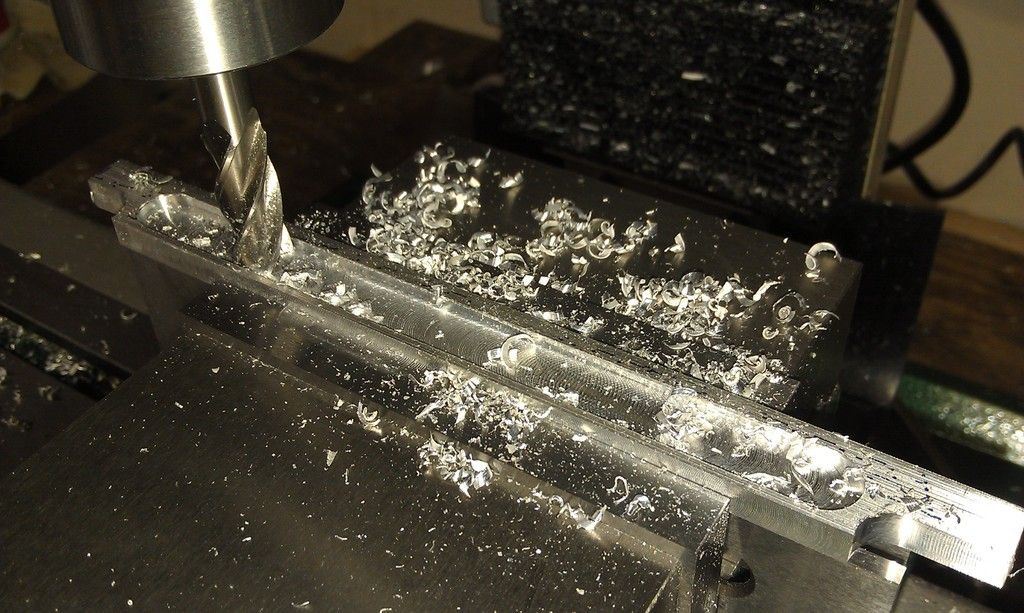

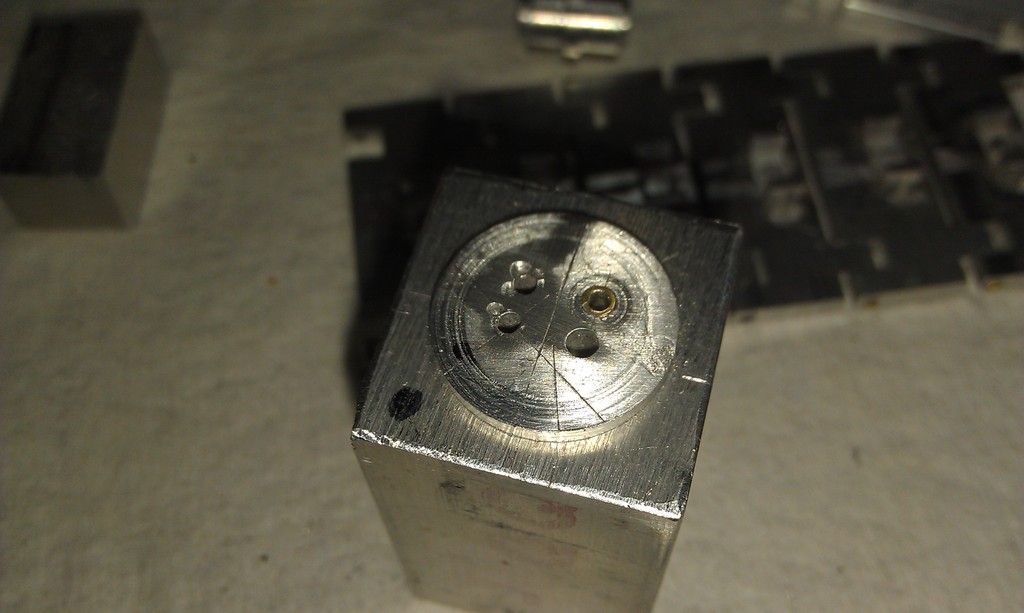

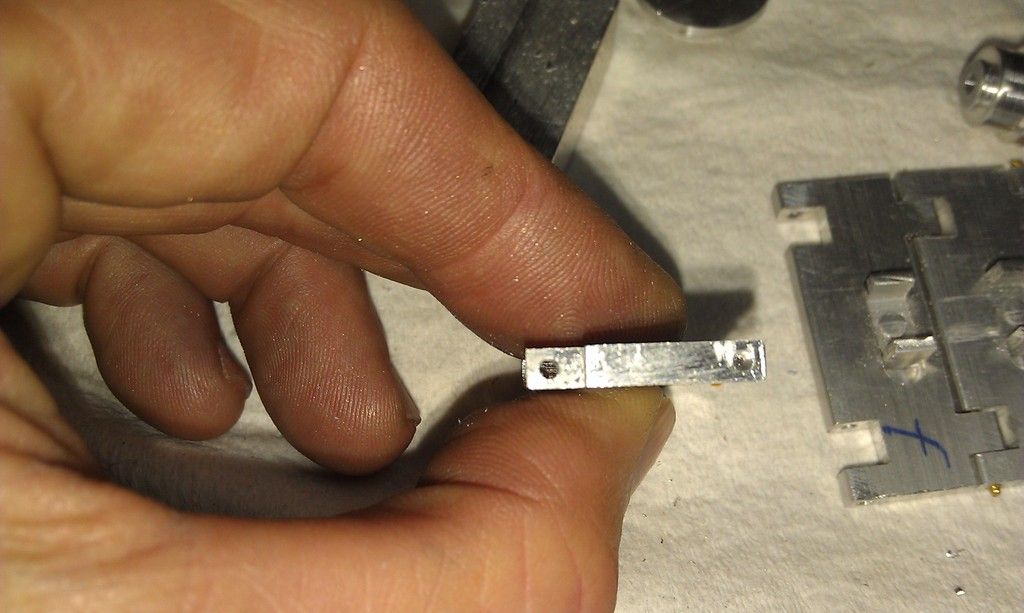

Wsky,

Ya, I have watched that one as well a bunch of other gear cutting videos. I haven't done it yet, but that is certainly one of my future projects for the mill and the dividing plates on the RT. Modelman, If you have other drawings you want to share that would be great! I really wish I had a PC and CAD software and here is the biggie, the knowledge and patients to learn how to use a CAD program. A lot of the reason I like to post project builds like this one is because it keeps me motivated. Here is the setup I am using to drill the link holes in the pads. They are pinned together with 1/16 brass tube. I had been drilling these holes on the drill press but the chuck is a bit off and I decided to try making a bit holder for a 3/8" collet to put into the mill. I have a R8 drill chuck for the mill but it won't close down small enough for a 1/16" drill. I just turned a piece if aluminum in the lathe and center drilled it 1/16". It us turned down to fit a 3/8" collet which is a common size for me for end mills so I can switch between them without changing the collet. The 1/16 bit is a good slide fit and I glued it in place with CA. Remember, I am a "noob" machinist so don't be afraid to offer tips or observations on my techniques.  Jim |

|

#31

|

||||

|

||||

|

Jim, Get me some dimensions. Maybe I can draw what you need and figure out your pitch problem.

You may want to shorten that drill some. or use a center drill first to spot drill first. That 1/16 drill probably walks around when you try to start a hole. I have a drawing from one of the Silver Spades track pads that may give a better idea how the tumbles engage. |

|

#32

|

||||

|

||||

|

Steve,

Thanks for the offer, I don't think I know yet if and how much of a problem I have. I need to finish riveting on the dog ears and make up a side frame and try it as a complete assembly. At this point I am still optimistic. Good idea on shortening the drill! I just checked my drill guide and it was not quite square so I milled it a bit. My inside holes where not quite center because the guide was leaning over a bit. Jim |

|

#33

|

|||

|

|||

|

Jim-I know nothing about CAD drawing. I am using a simple, free program I found online. It is easy to use and can be accurate with measurements. Do you have a way to hold the brass pins in place? Just a suggestion-use music wire-it is available in sizes .060",.062",.064" etc.. You could drill one side of the pads for a press fit and the other side for a slip fit and the pins would stay in place. Maybe you have all this figured out. Keep working and posting pictures-

|

|

#34

|

||||

|

||||

|

Tom,

I wanted to use brass tube or solid brass so that it wasn't as hard as steel. I would rather replace the pins vs making new pads as the holes wear. I was thinking about just putting a spot of glue on the outside end of each pin? I don't want the to be too hard to remove, I think maybe CA glue would be okay, I can heat it up and get the pins out as needed. Been trying to finish up the drilling, then I need to do the little dog ears. Thanks for your interest! It keeps me motivated, it is easy to get bogged down bay the shear number of parts I'm making...  Jim |

|

#35

|

|||

|

|||

|

First, I am wondering, and it's going to be a simple answer I'm sure....probably make me bang my head and say, of course. But, what is CA glue?

Quote:

On the long drill bit... You can buy stubby drill bits, they don't walk as easy. And like 9W said, if you spot or c-drill first, it will keep your parts more reliably consistent. And the drill will drill straighter as well.

__________________

Life: it's all about the ride! |

|

#36

|

||||

|

||||

|

CA - cyanoacrylate. It is crazy glue and a bunch of other names.

I just used the dremel tool and shortened the bit a bit.  with the drill guide I am getting a pretty good and well located hole now. I have to be careful, if they start to wander off center the pads develope a twist as they get pinned together. It is sort of an interesting problem, since I drill one end and flip it to the other end and side. So, any off center issue is doubled and then the twist sets in. with the drill guide I am getting a pretty good and well located hole now. I have to be careful, if they start to wander off center the pads develope a twist as they get pinned together. It is sort of an interesting problem, since I drill one end and flip it to the other end and side. So, any off center issue is doubled and then the twist sets in.Jim Jim |

|

#37

|

|||

|

|||

|

Jim-I will keep watching. This is the only build going on here that I am interested in. Before your drill guide gets to loose and off center maybe you could drill it out and press a brass tube inside it. The brass possibly will last longer than the aluminum. If the holes get off center the pads will be a mess. Ain't machining fun!!!!

|

|

#38

|

||||

|

||||

|

Tom,

Good idea on the brass bushing. I have basically checking every one I drill. I had been thinking if the cap in the drill guide starts to hog out I would make one in steel, but a brass bushing sounds easy. I was getting crazy drilling holes and had to do something different for a while! If all the side rails turn out okay I will try to make them in steel to add a bit of weight. I'm thinking I may also add some lead ballast where I can as well.   Jim Last edited by Rvjimd; 06-05-2015 at 02:06 PM. Reason: More |

|

#39

|

||||

|

||||

|

I am also available to help with cad drawing if needed. Just send me a PM with the dimensions you need.

Nice work and I will be watching this thread for the duration

|

|

#40

|

||||

|

||||

|

Car5858, thanks for the offer! I'm using some photos of drawings that .steve posted on another crane build, for now that is getting me by.

Tom, This picture is for you, I had to adjust it after I put the bushing in the cap, but it makes it easier to see and should last at least thru the remainder of the pads I have to drill.   Here is a side view of a drilled track pad.  ] Jim Last edited by Rvjimd; 06-05-2015 at 04:34 PM. Reason: Added second photo |

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

| Thread Tools | |

| Display Modes | |

|

|