|

|

|||||||

| Construction Equipment Tech Hydraulics, Electronics, General Engineering, ect in constr equip |

|

|

|

Thread Tools | Display Modes |

|

#1

|

||||

|

||||

|

Hey Everyone,

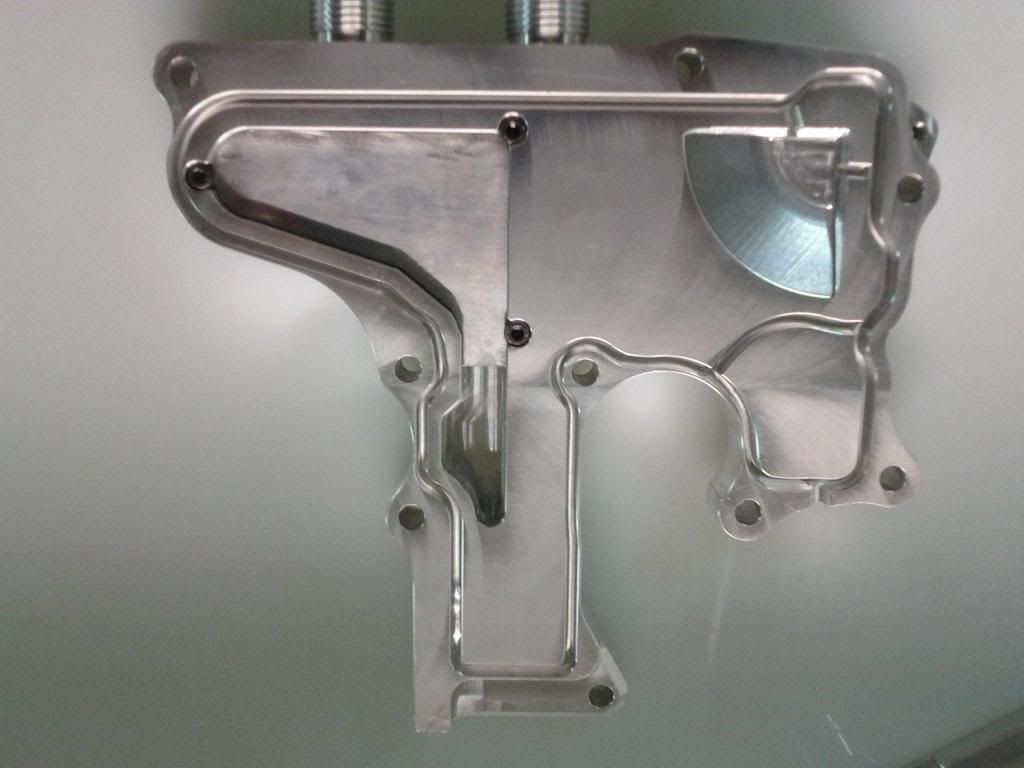

I haven't been to busy on the forums as I am working full time and just finished doing some night classes for school. So my free time has been limited, and still is as I am building a new engine for my car.  Anyways I have noticed quite often that lots of the builders on here; including myself, are always challenged when it comes to making tracked equipment, due to how many track links are required. And unless you have a CNC mill and lots of free time it is a real hassle to make them all. Well I may have a solution for us all! Through the company I work at I have been able to get a connection with A machining company with very reasonable rates, especially so for high quantity runs. They do most of the machine work for all the custom CNC parts I design for work for the cars that come in. I was thinking that if there was a great enough need I could; along with some help from you guys, draw up some of the most useful and required track pad designs for all the builds and sell them at a very reasonable price. Although I can only receive a quote from the company once I send them a drawing and required quantity. So if you guys are interested in this let me know so we can get the ball rolling. I was thinking that there may be 5 different tracks you guys would need and I could have them made by the hundreds. Unfortunately I don't know off the top of my head how much one pad will cost but once I have one drawing done I will be able to get a quote relatively quick as the company I work with is very quick. Here is an example of one of the parts I drew in Solidworks and had made for the new Volkswagen's just to show the quality of parts they make: CAD rendering:  Underside:  Top Side:  Thanks! And let know if you would be intrested! Chris |

|

#2

|

|||

|

|||

|

I would be very intrested in some metal trackpads, as you may know i have a Vario/Fumotec excavator and there are a few more on here so im pretty sure almost all of them would like metal trackpads.

I could gladly send you the dimentions for the plastic pads i have right now, or even if needed send you a pad if you need it to measure yourself? This would be the icing on the cake for me and are of course willing to pay a reasonable amount for them, let me know if you need more info! Great idea! Here is a pic of the plastic one, im sure this could be used on other excavators as well if you use the same pitch sprocket and idler wheel. [IMG]  [/IMG] [/IMG]

|

|

#3

|

|||

|

|||

|

I would prefer tripple grousers but I could stand double grousers as well, to make both would be almost to good!

|

|

#4

|

||||

|

||||

|

Hey Azonic!

I think if you could send some dimensions that would be easiest seeing as you are located in Sweden and I am out In BC Canada. So it might take a while to get here! If you could maybe give some dimensions or hand draw blue prints I'll draw them up and we can from there! I'm glad you could use this offer! I was just sitting at work thinking, hey why don't I do this? I need some tracks and Im sure everybody else could use some. Chris |

|

#5

|

||||

|

||||

|

So this is off topic but... What happened to your wheel loader Chris?

|

|

#6

|

||||

|

||||

|

Sitting beside me actually haha. I just finished some school courses and got access to the shop at work so I am going to try and get back on it asap! Along with the 100 other things going on hahah. I hope to post an update soon!

Chris |

|

#7

|

|||

|

|||

|

Quote:

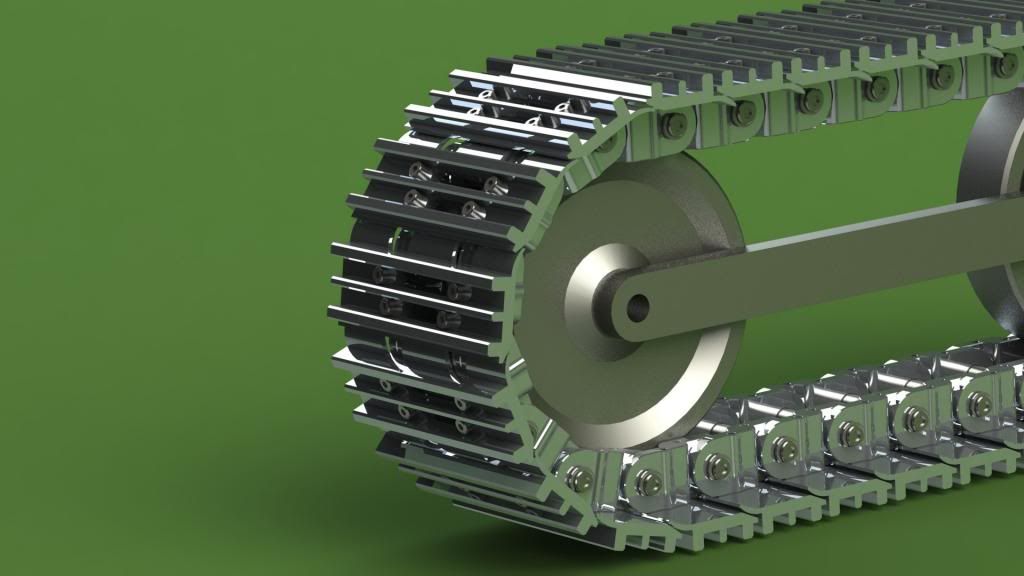

Like i said i would like to have triple grousers like on the 1:1 machine, i post some pics of how i like them to look. Also, i dont know if its to complicated/time consuming to machine the track pads in one piece like my plasic ones, or if its easyer to make them separate pad+link and bolt together, what you think? Here is how i would like them to look.

Last edited by Azonic; 02-16-2013 at 10:36 PM. |

|

#8

|

||||

|

||||

|

A triple bar for excavators & a single bar for dozers would be a good start.

The Vario track is a bit larger in stature to other 14th track models... might be the same size as IHbuilders 385's... a 1st run of a 1000 links would cost what per link? Have you done any drawings yet? I think your greatest challenge in all of this is staying under $8/link.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#9

|

|||

|

|||

|

Same principle could be used for aluminum track pads. I work with an aluminum extrusion shop on some parts. A die that size and profile would probably cost me around $2k by the time I got the first 100lbs of material from it. So your talking a triple and single grouser die for $4k. The links I would have to look at closer but may not be that difficult given some creative fixturing. Hardest part would be a couple of the inside corners need to be square.

Anyway, even doing it this way, yes you'd probably be up in the $1k per set of tracks. I'd have to run the numbers to be sure, could be lower but I still have to amoritize the cost of the dies over a few sets. Doing this way width of tracks would be easy to adjust, size changes would mean a whole new die. Then for some wear resistance could hard anodize all the parts (which requires milling them slightly different). Steel..... I have seen a couple places that do extrude steel shapes, have no idea on what they cost but can imagine its considerably more. Oh and I forgot all about pins.

__________________

Jeff |

|

#10

|

||||

|

||||

|

thanks Jeff

yes you need to factor in pins and screws . yes you need to factor in pins and screws .

__________________

RIP FreddyGearDrive 2-12-59/12-19-11 To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#11

|

|||

|

|||

|

And I suppose they would have to be hex head bolts too......

__________________

Jeff |

|

#12

|

||||

|

||||

|

OH yea

in steel in steel

__________________

RIP FreddyGearDrive 2-12-59/12-19-11 To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#13

|

||||

|

||||

|

What pitch would be of most use for the majority of tracks are we looking for? What would be the the most popular material. Aluminum, Brass, or Steel?

|

|

#14

|

|||

|

|||

|

I may have thought of a cheaper way to start them. Probably still out of aluminum but could be 7075 or 6061 material and hard anodized. If you guys can figure out a common pitch (or 2) and let me know some dimensions I could figure out pricing. If it worked out I would be willing to build them as a stock item and add them to my "store" on here.

Steel may be possible this way, but would cost a bit more than alum due to machining time, tool wear, etc

__________________

Jeff |

|

#15

|

||||

|

||||

|

Or to simplify it even more for you, you decide your own pitch & sell drive sprockets with the tracks... better for you than trying to accomendate the various that's already out there.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#16

|

||||

|

||||

|

Has anyone come up with a print design on these, or what size the final piece would be? I would have no problem pricing out material etc and rates to run these. I'd like to see if I could do a batch price to cover everything needed, instead of a breakdown pricing setup

--Dan

__________________

To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#17

|

||||

|

||||

|

Right now I am working with Azonic to create a scale, metal track setup that will be a direct bolt on to Hitachi Zaxis machine and other machines that use that pitch. I have not got a quote from my machine shop but it should not be sky high as I may be ordering in the thousands if there is a need.

Also these will not be a $1 per link type of item as it looks like the majority of people building tracked equipment understand the cost to these pieces of metal art. They are meant to be a fair cost, scale piece of machined metal, either 7075 aluminum for its hardness, or stainless depending on the cost. I'm not trying to be rude at all but I am not trying to make a profiting business by having injection molds and everything made like CDM mentioned. Just simply an option for people needing tracks. Because chances are if you want to buy some nice tracks you are not converting a Bruder model, you want a beautiful, scale, piece of engineering and pride. If all goes well I may decide to sell "kits" if you want to call them that, they would include a ilder wheel, sprocket and roller wheels that would most likely only have a spot drill in the center so you can adapt them to your application. I will post a price per link as soon as I have finalized the details. Here is a CAD rendering of the design Azonic and myself are working on.  Any questions lemme know! Chris |

|

#18

|

||||

|

||||

|

with that being said they should not be expensive though as they will be machined in high quantity runs; 300+ each run. I am dealing with my machine shop right now so I should have a price pretty soon! I will post it asap!

Chris

|

|

#19

|

|||

|

|||

|

I might be interested in a set. Ed

|

|

#20

|

||||

|

||||

|

As I don't yet have any completed tracked equipment myself I'm not positive on the wear levels they actually produce to the tracks themselves. I'm noticing that quite a few of you guys seem to be worried about some aluminum being to soft for them, is changing from 6061 to 7075 going to be that much of a gain in the expected life span of the tracks? I know tensile strength is increased pretty well but if its from the edges of the gears digging in I'm not sure how much more it would help?

Only reason I'm asking is because price difference in materials will add up quickly from 6061 to 7075 or even 2024. If 6061 would work fine I have enough loose pieces I could probably make a few full sets for prototype testing Could you guys fill me in on the life span expectancy as well as some ideas of the actual wear you see on your current tracks. --Dan

__________________

To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|