Well it's time to start building this.

I feel like I've learned enough to be dangerous so here goes my first cable machine if I can get this one right .... or close to it... I have a bunch more I want to do....

( disclaimer the dates and modeling information is just what I found on the internet they may or not be accurate I just took it at face value)

First this is a Structo front shovel from about 1953ish as far as I can tell, it appears to be modeled after the Buckeye Clipper from the late 30s early 40.

I want to keep the original look of the toy as much as I can and still make it functional, I will have to alter it but I want to keep it at a minimum. I will try to make it look as close to the Clipper as I can but may use a Priestman style boom and dipper configuration...

The plan is to cut the cab off the base so I can lift it off to get to the interior, I'm going with a lift off shell because I cant see any good place to cut the cab roof off and not have an ugly cut line out where it's really visible.

And since one set of line go thru little holes I'll either need to "slot" the cab or just open the front up completely

I got that part done, it went easier than i thought.... I used a dremel with a cut off wheel they welded this thing one in about 2 inch runs... no spot welds.The sheet metal is way to thin to use as the base so I'll have to make something...

The running gear is off the shelf Huina 1550 with the upgraded metal slew gear and motor. I wasn't up to try and scratch build this part....and this piece works pretty well.

There aren't a lot of pieces to this thing....

I decided to just cut the front face out to expose the cabling drums and make it easier to lift the top off, it will impact the "streamlined" look of the clipper but I need to be able to easily get the cab off...

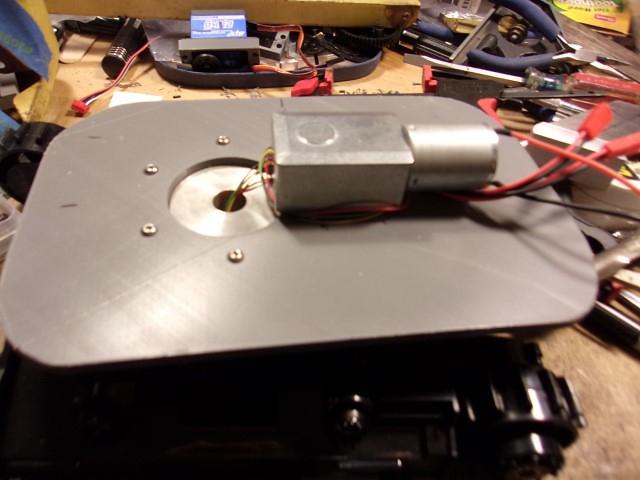

I 3d printed a base plate, it's 6mm thick, just a solid slab of PLA this way I could design in the openings for the slip ring and slew gear....

I just made it a square piece because the cab is kind of odd shaped and none of the corners were the same so I just printed a big square and hand cut the corners to fit.

The base, slip ring and undercarriage went together way better/easier than I thought they would..

[

I also needed to make a "dust" ring or collar to cover the slew gear on the Huina it's part of the cab base.