|

|

|

|

#1

|

||||

|

||||

|

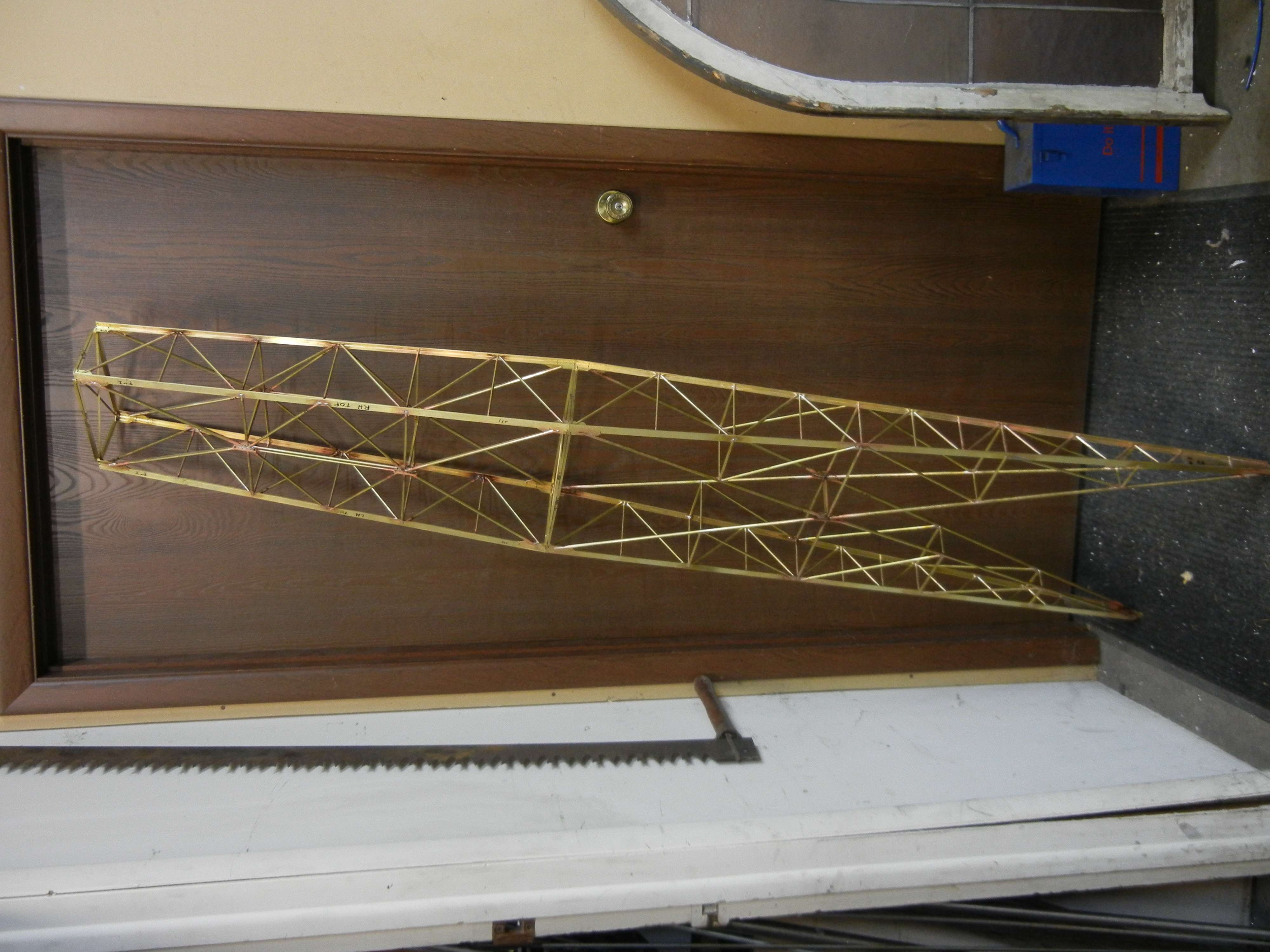

I can't try the first section yet. If anything I'm going to just wire tie it under the temporary boom for looks and to keep fingers from touching it while at the show. But to answer your question Tom, It is very strong so far, much stronger than the temporary one that's just tacked together 1/8''x1/2'' flat bar.Also the safety lines add needed strength to keep it from buckling. I am almost finished milling angles and notching the tubes on the second section. After that is done I have to work on those dreaded splice plates again that took so long on the first section.

|

|

#2

|

||||

|

||||

|

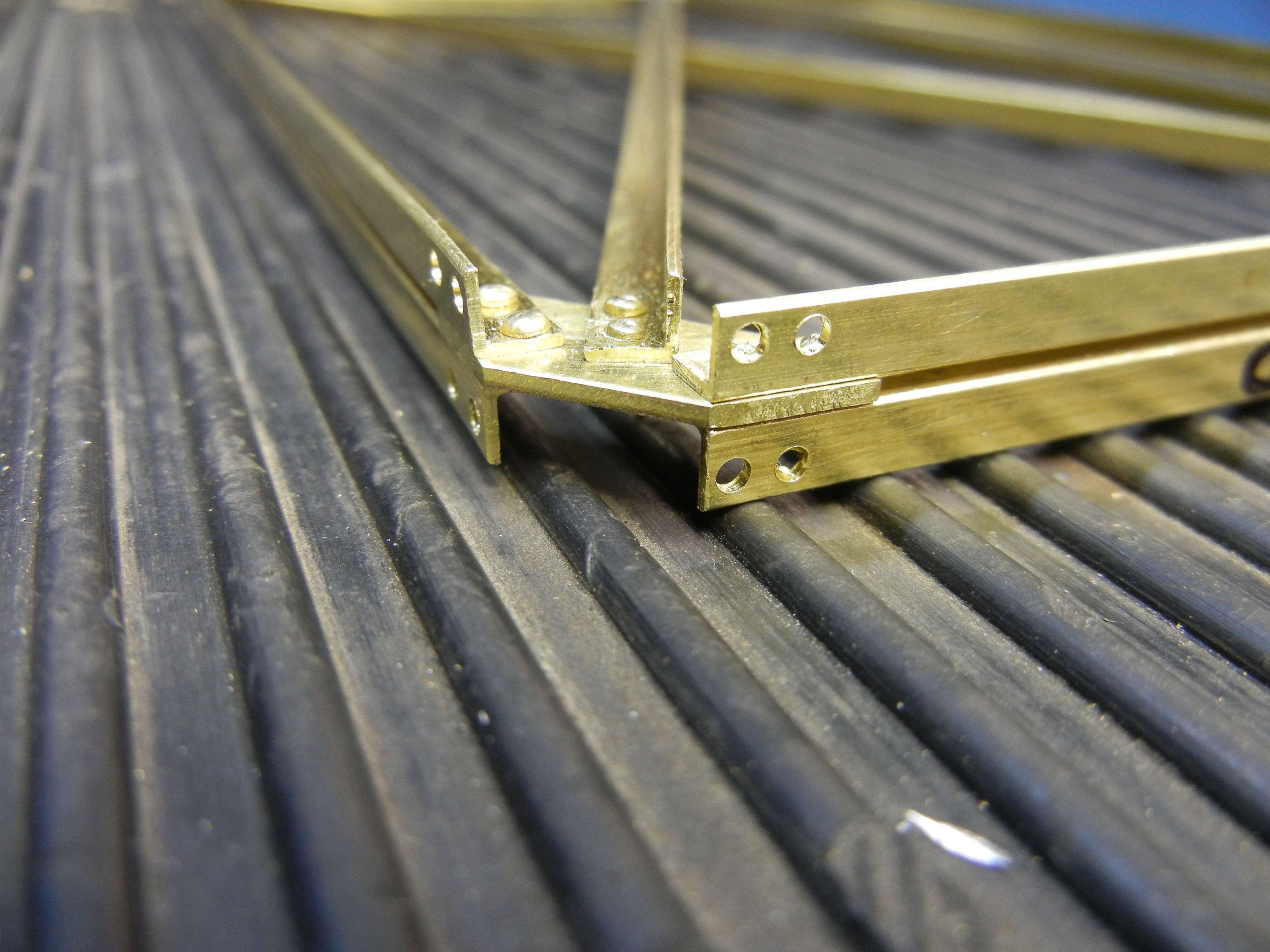

More pieces this week. I have 66 done but still need 39 more for this section of boom.

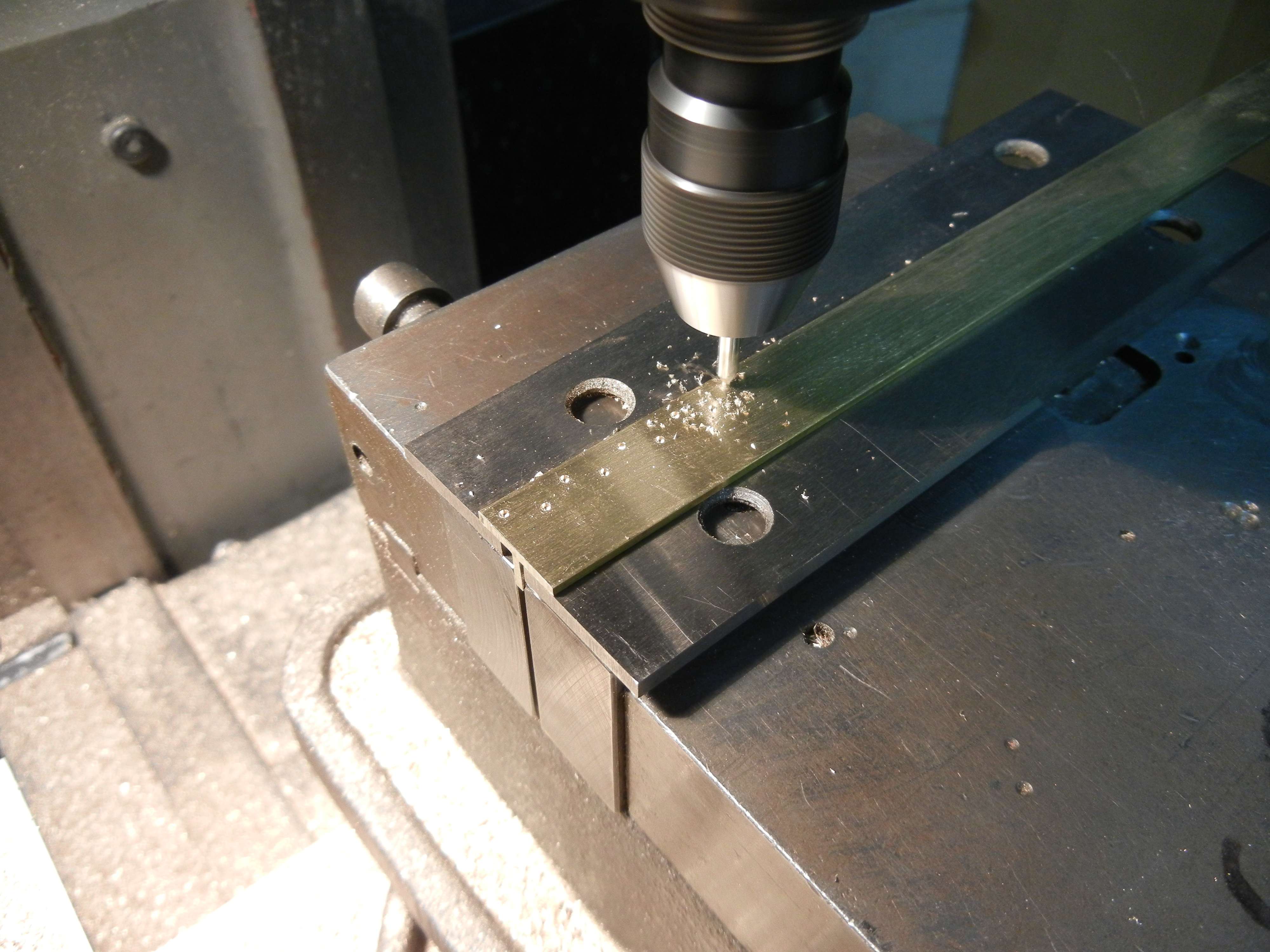

Drilling the chord ends 224 holes total 0-80 to tap.on these  A nightmare of angles

|

|

#3

|

||||

|

||||

|

very cool!

__________________

Rc's are like pringles. You can't have just one!! my YouTube is - To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. Subscribe!! My Facebook - To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#4

|

||||

|

||||

|

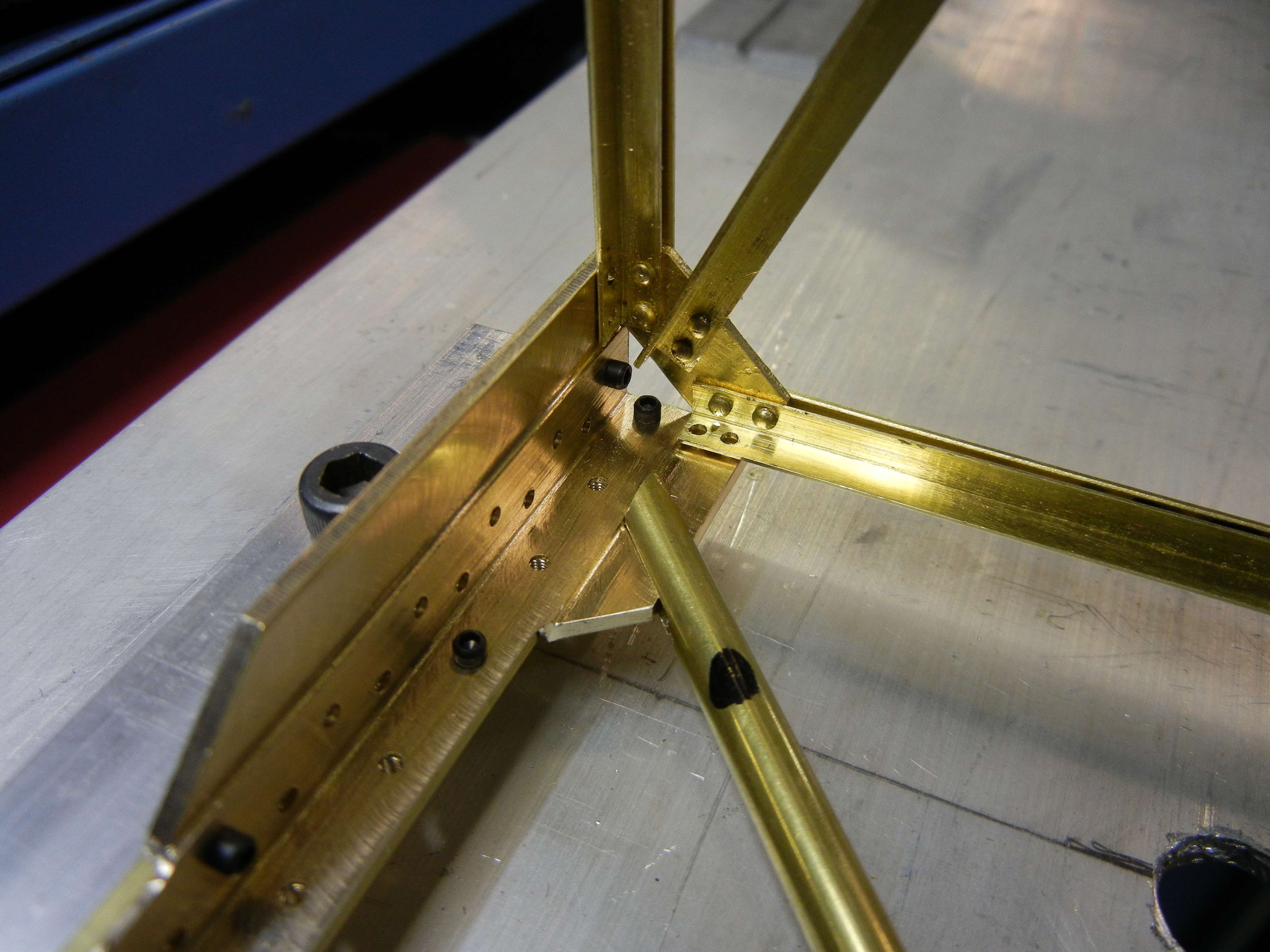

I got the second section pretty much done this week on the 9W project.

Still need the 3rd section. .040'' rivet detail   Fitting up the splice what a time consuming job this was trying to install all the 0-80 socket head screws  ready to solder  second splice  100' or 75'' scale boom

|

|

#5

|

||||

|

||||

|

Wow Steve Looks awsome...So close to being done for the cabin fever and wish I could be there to see it in person..Im totaly impressed ...great work

|

|

#6

|

||||

|

||||

|

Quote:

I was saying around here in the past, the coal co's just push all the trees into the pit and cover them up with a D11 I was saying around here in the past, the coal co's just push all the trees into the pit and cover them up with a D11

|

|

#7

|

||||

|

||||

|

that's just crazy!!

__________________

Rc's are like pringles. You can't have just one!! my YouTube is - To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. Subscribe!! My Facebook - To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#8

|

|||

|

|||

|

Looking great! hard to believe it has to get bigger yet.

__________________

Jeff |

|

#9

|

|||

|

|||

|

Fantastic work Steve, looking forward to see it finished. Is everything done inside, drums, brakes.....?

what´s the capacity on bucket? Dan |

|

#10

|

|||

|

|||

|

Steve great job looking forward to seeing it next week. Ed

|

|

#11

|

||||

|

||||

|

All that brass!!!! What a monster!! Hope to see it next week!

Lynn |

|

#12

|

||||

|

||||

|

Thanks again everybody.

Quote:

Does anybody know of a source for lighting? I want some big spot lights on the boom. I was thinking of buying Mini Maglite reflectors and build my own using their Kypton bulbs. I found I site that has model boat spot lights. I may get one and see how it works. Last edited by 9W Monighan; 01-07-2011 at 04:28 PM. |

|

#13

|

|||

|

|||

|

On my model I will try using Plexi cut to size, drill a hole on rear and put a white LED.

The Plexi was bought as scrap at local dealer, LED´s are 5 for $4. Plexi comes in different sizes, sheets, rods, I use 1" sheet (part of) and cut with bandsaw. My LED´s are 3,2v 20mA, 2 connected togheter can be runned on reciver battery.  The brass strip will be used as guards outside lamps (on CAT models). Dan |

|

#14

|

|||

|

|||

|

Well Steve have you got it all packaged up for York next week? I will see you there. Ed

|

|

#15

|

||||

|

||||

|

No, I'm starting the third section and hope to get it pretty much complete this weekend. I won't have the point sheave done so I'm going to just clamp a temporary one on.

|

|

#16

|

||||

|

||||

|

Steve,

Talk to Willy (customrcmodels) about your lighting. He uses some 5mm LEDs on his tanks and trucks that you can not look at as they are so bright. They make the stock Tamiya headlights look like candles! Looks like I will not be able to make the York, PA show next week  Was able to get new computer and software for my CNC Sherline mill at a very good price so all of my available funds went there instead. Hope to see your dragline next year if all goes well. Was able to get new computer and software for my CNC Sherline mill at a very good price so all of my available funds went there instead. Hope to see your dragline next year if all goes well.Lynn |

|

#17

|

||||

|

||||

|

Quote:

Sorry you can't make it. Let's see some pictures of your new mill set up. |

|

#18

|

|||

|

|||

|

Steve-this looks really great! Your patience will be rewarded!!

|

|

#19

|

||||

|

||||

|

Thanks Tom, I am busy trying to get the 3rd section pretty much done this evening but got cut short from running out of oxygen on my torch. I have all the pieces made and about 3/4 of it is soldered together. I haven't started on the point yet but I'll still be putting a block of wood up there for the sheave temporally so we can run it this weekend.

|

|

#20

|

|||

|

|||

|

nice work i like all the detail jusy can't put it into words lol one day i will see your drag line model in person

__________________

I built this thing and have it working now what do I do with it? |

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|