|

|

#11

|

||||

|

||||

|

I think the trans in this trk dates back to 1998

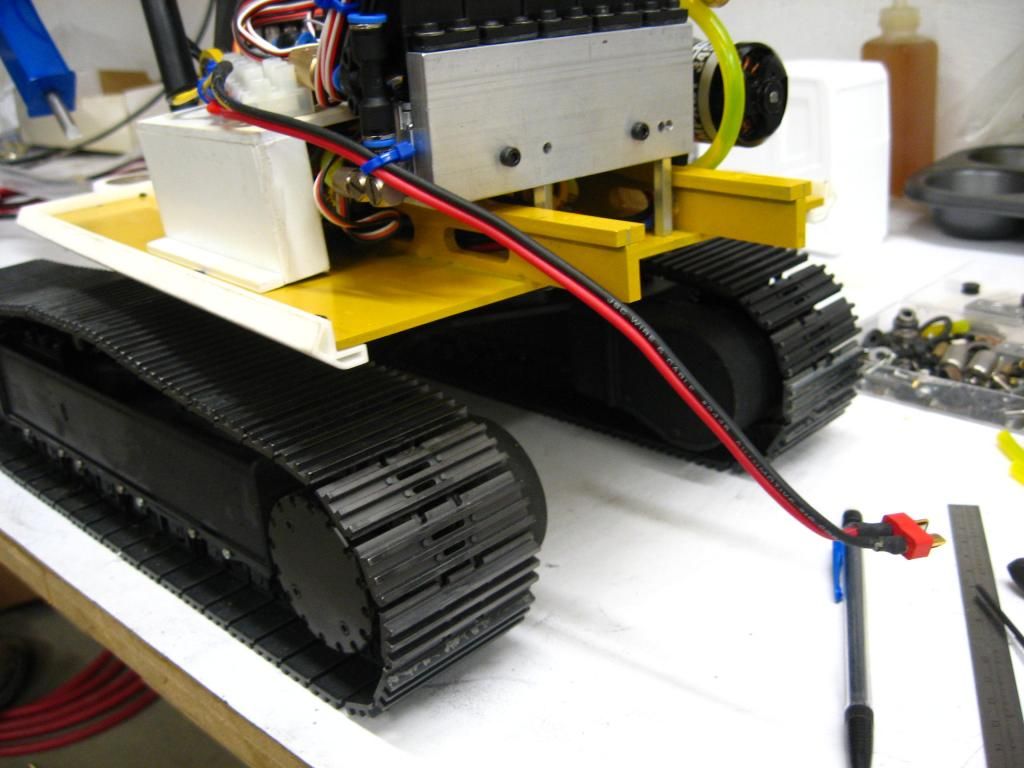

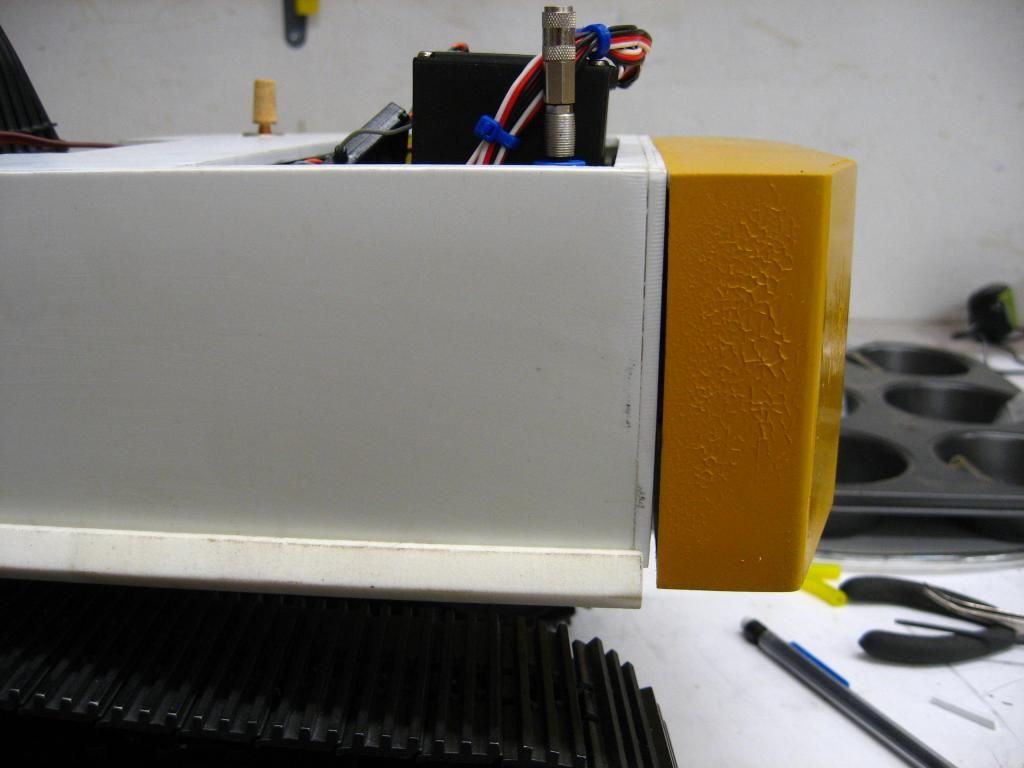

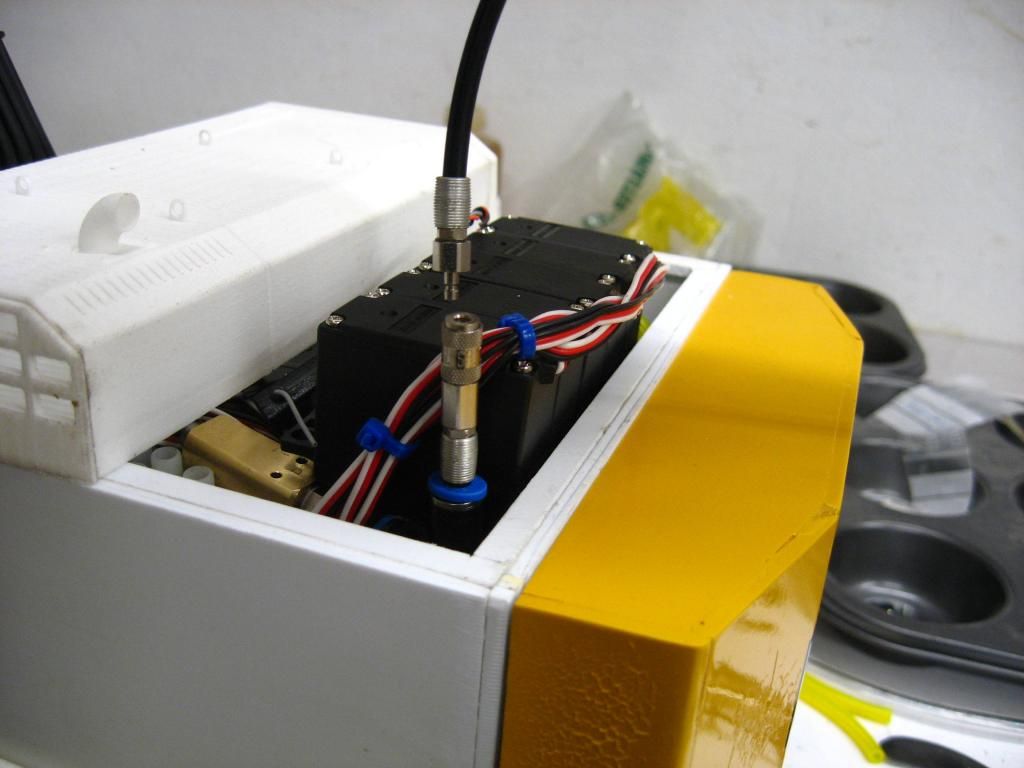

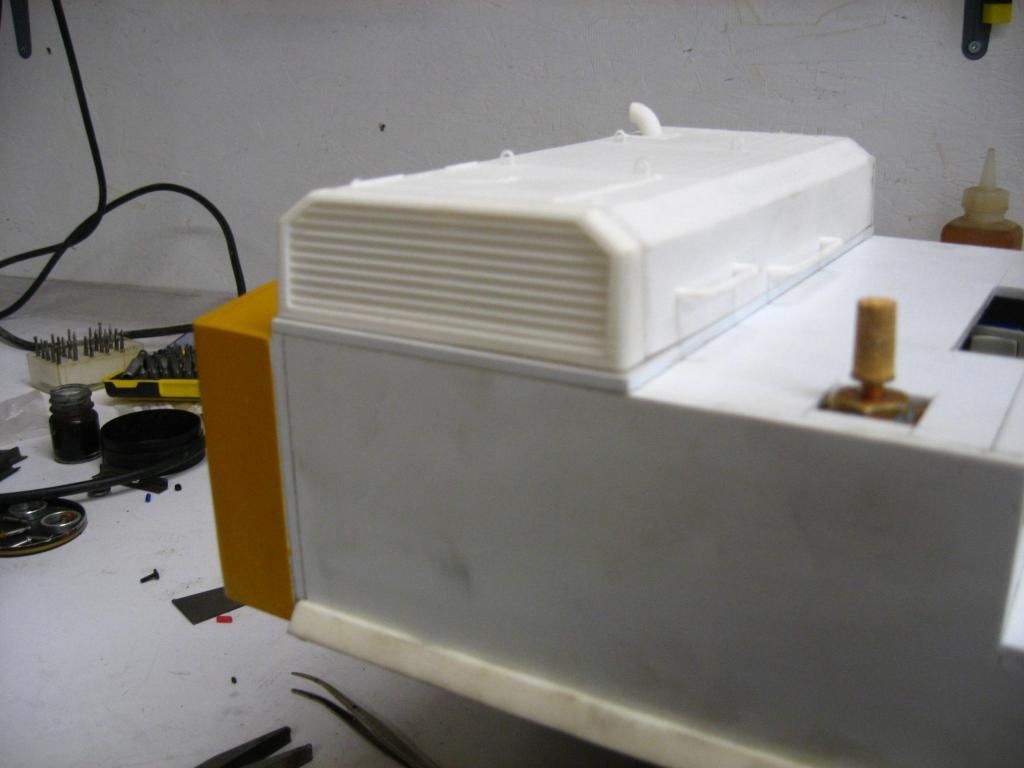

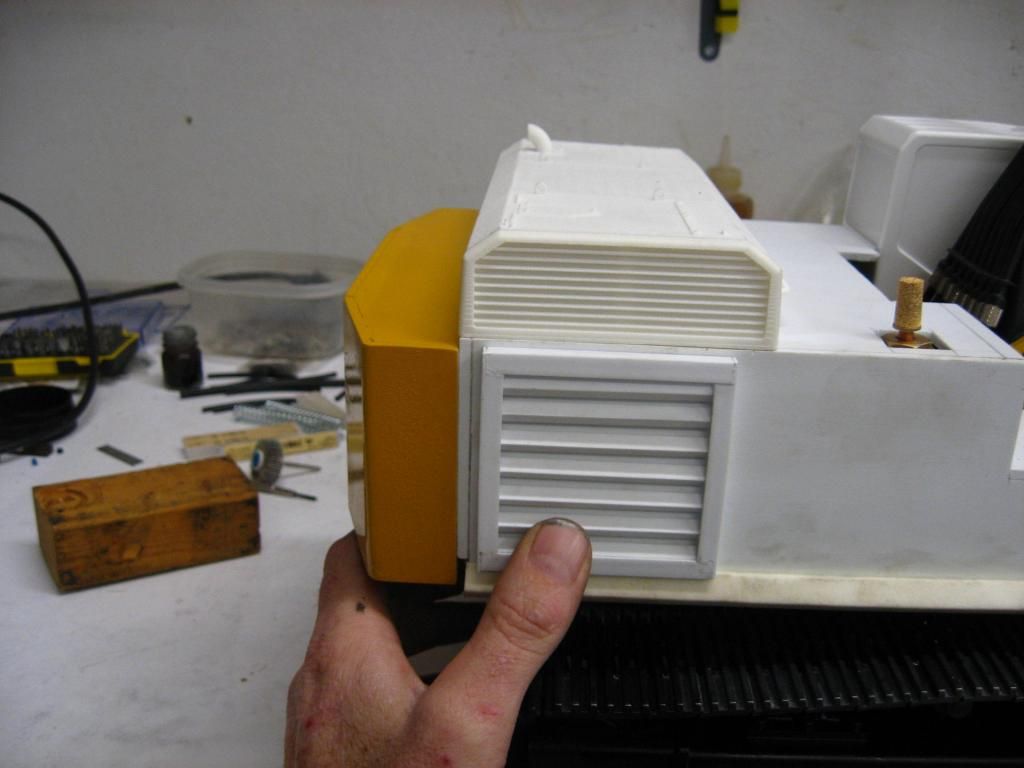

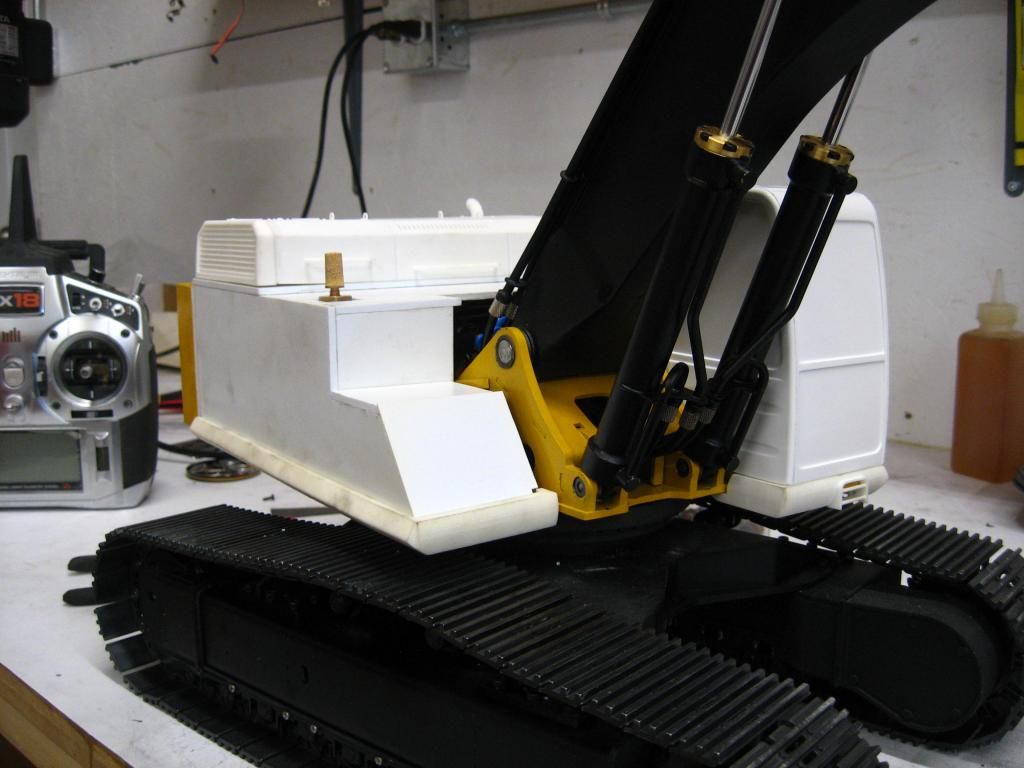

. The aluminum gear on the left was the motor pinion, the middle aluminum gear was on top shaft of trans & the gear change disc is out of the front of trans, I change that too b/c the center had quite a bit of wear & so did the shift fork groove. . The aluminum gear on the left was the motor pinion, the middle aluminum gear was on top shaft of trans & the gear change disc is out of the front of trans, I change that too b/c the center had quite a bit of wear & so did the shift fork groove.  I came up with this idea yesterday to keep the inside of conveyer belt on crusher clean... I haven't taken the time to try it yet. The brush came from a car window ice scraper.    And here's the jungle of hoses & wiring I've been trying to stuff under the hood.      I made this plastic box mostly for the purpose of having somewhere to mount the on/off switch so I could reach it without removing the hood. The speed controls for pump & swing are inside there.   I painted the counter weight, then decaled it and then clear coated to protect/seal the decal... for some reason the clear had a reaction with the paint  I don't have any extra decals, 5 feet away you can't see it & probably before too long I'll have it dirty & all scratched up anyway. I don't have any extra decals, 5 feet away you can't see it & probably before too long I'll have it dirty & all scratched up anyway.  The body parts I made, everything butted together so well before the electrical & hyd plumbing.    This disconnect is where my gauge plugs in... once the pressure is set (20bar), really don't need it anymore & don't have the space for it anyway.  I have a variety of fittings, but of course not exactly what I needed for a simple connection of the gauge...   I made the engine hood not quite high enough for this 3D printed piece to fit, added a 3mm shim, now it fits.  I unbolted the pump from the floor so I could get a good grip with my fingers on the suction & return lines... presently no more leaks. I haven't added any inserts to the return lines.  I got it all tuned up: the tracks, the swing, the pump, all 5 valves; everything works, mixes are programmed. I even tried out the hammer, pounding into a piece of wood 2x4 a quarter inch deep is where it stopped. Now to just finish the bodywork, paint it & off to the basement.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

| Currently Active Users Viewing This Thread: 3 (0 members and 3 guests) | |

|

|