|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

Thread Tools | Display Modes |

|

#31

|

|||

|

|||

|

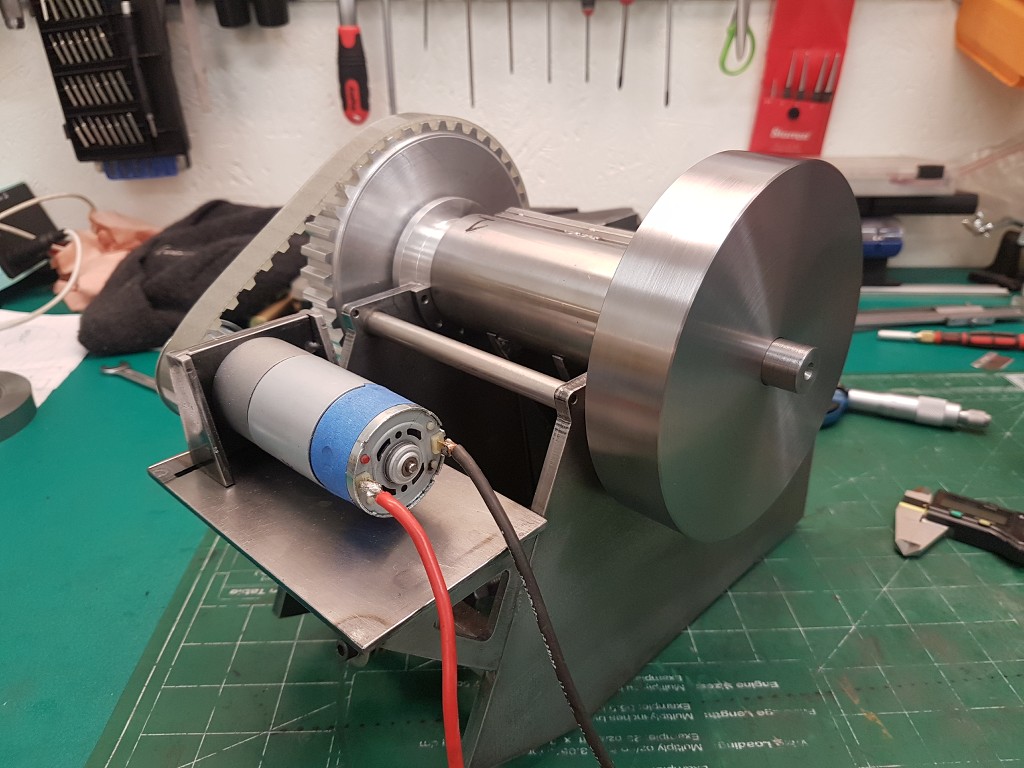

Now it was time to turn the flywheel and the extra weight for the beltwheel.

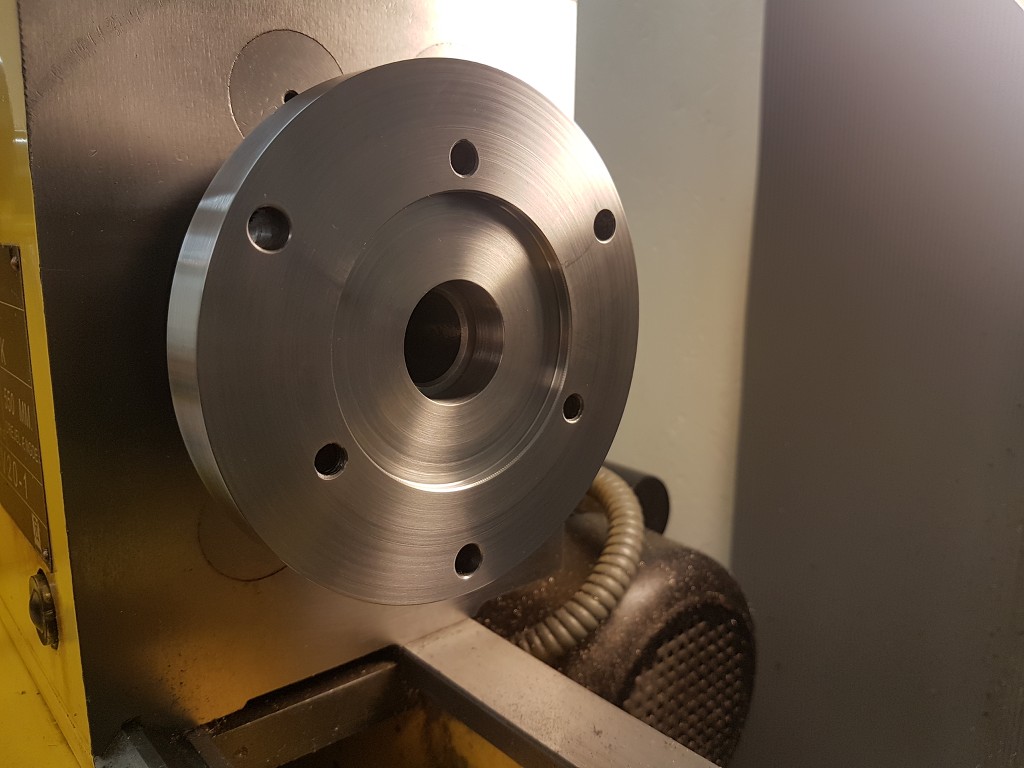

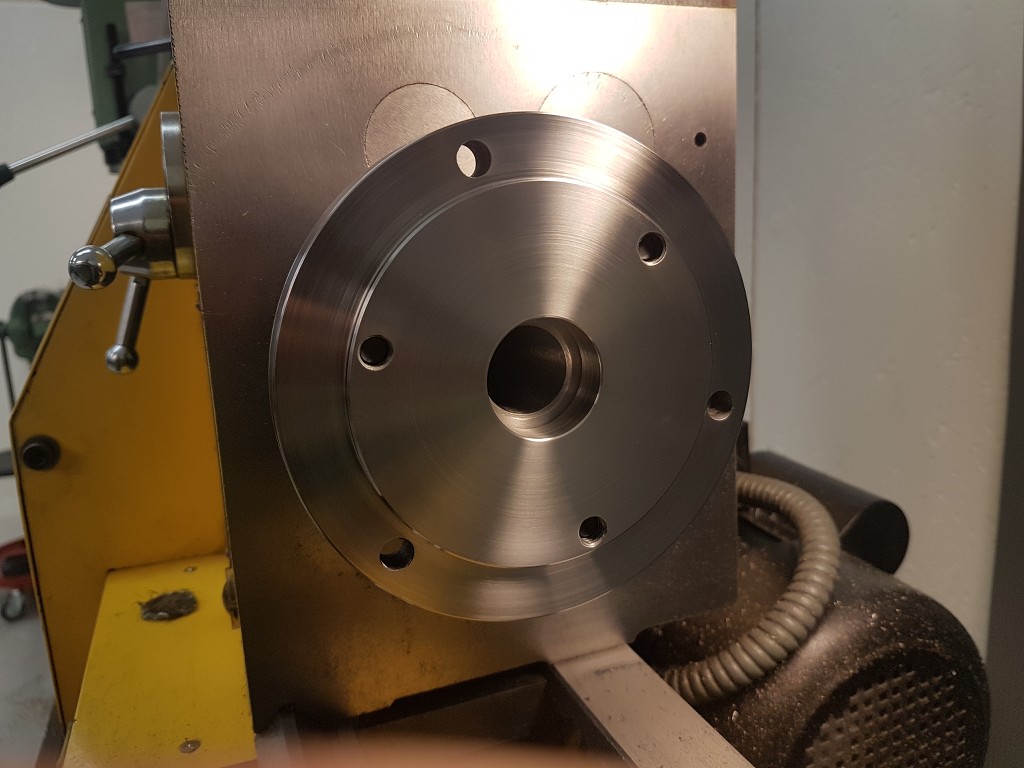

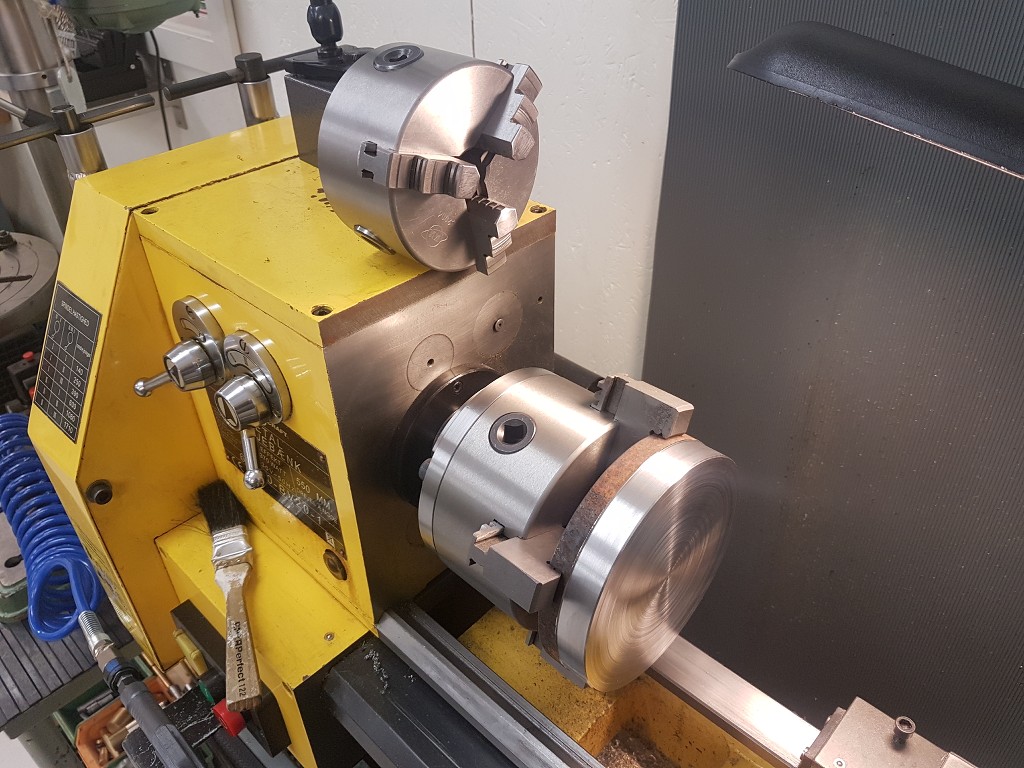

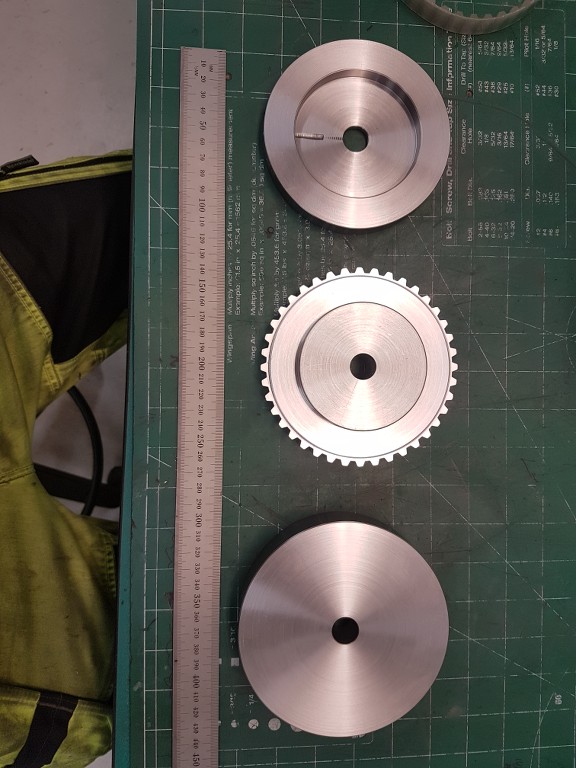

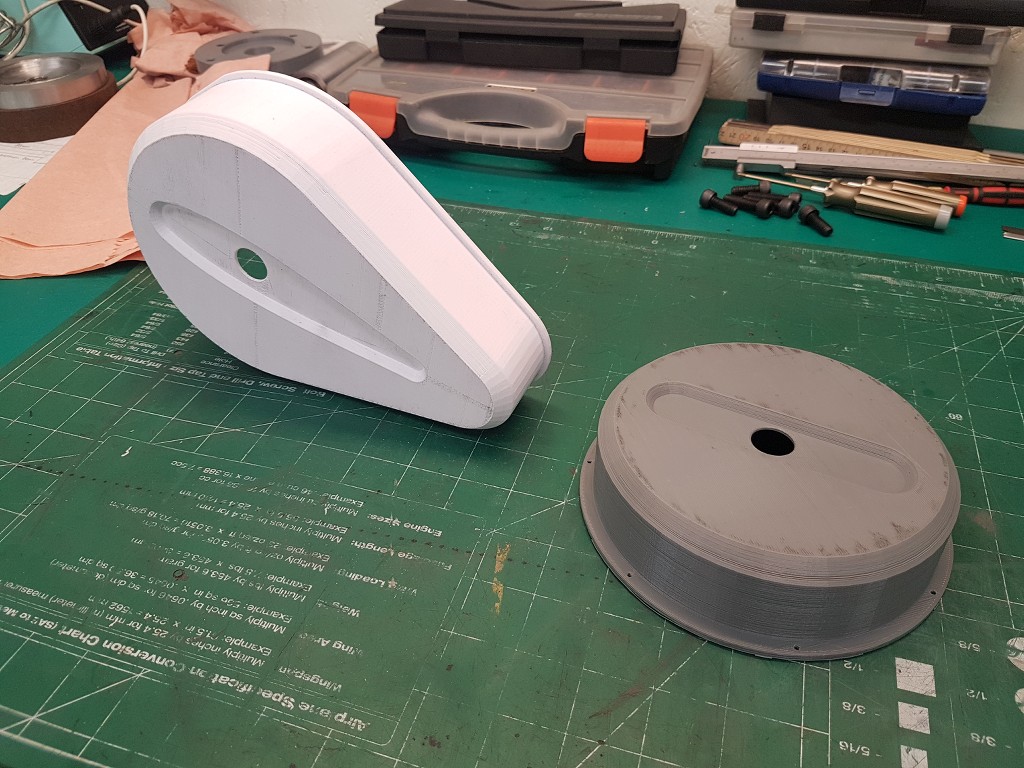

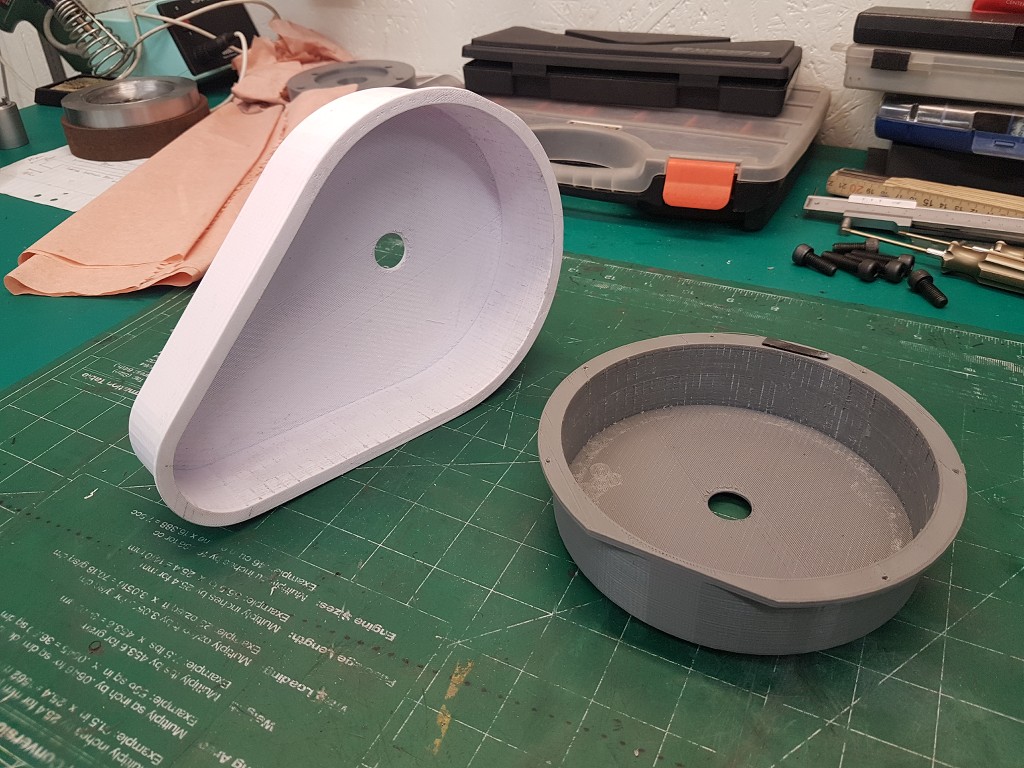

I only had a 100mm chuck on my lathe and it cant hold pieces as large as the flywheel so I had an chuck adapter made by a local machineshop to get the boltcircle right and then I turned the last steps myself. Now I can fit a 125mm chuck and this lathe will last me a few more years!  Here´s some progress on this project. First I turned the internal hole for the flange mount on the spindle.  Then flipped it to turn the outer flange to fit on the new chuck. I had 0.01mm runout on the spindleface with new backplate.  Here mounted and started to turn the flywheel, I had a runout on the chuck on about 0.03-0.04mm, that was measured on a drillbit in the chuck. Good enough for me.   And just a pic of my 10 year old chinese lathe, it has served me good over those years.     Also both covers are printed, also made on a cheap Wanhao 3D printer.

|

| Currently Active Users Viewing This Thread: 2 (0 members and 2 guests) | |

|

|