|

|

|||||||

| Euro Style Trucks and Trailers A place for the Euro style trucks single and twin axle trucks and trailers... |

|

|

|

Thread Tools | Display Modes |

|

|

|

#1

|

||||

|

||||

|

Oh dear, today was the "comedy of errors"

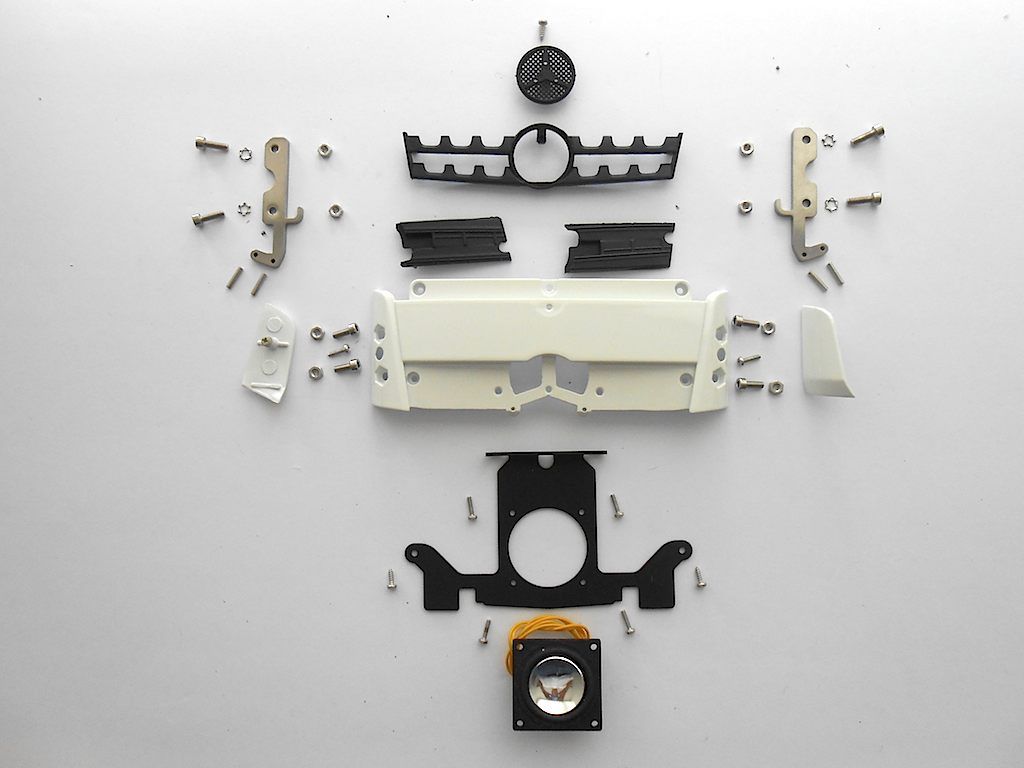

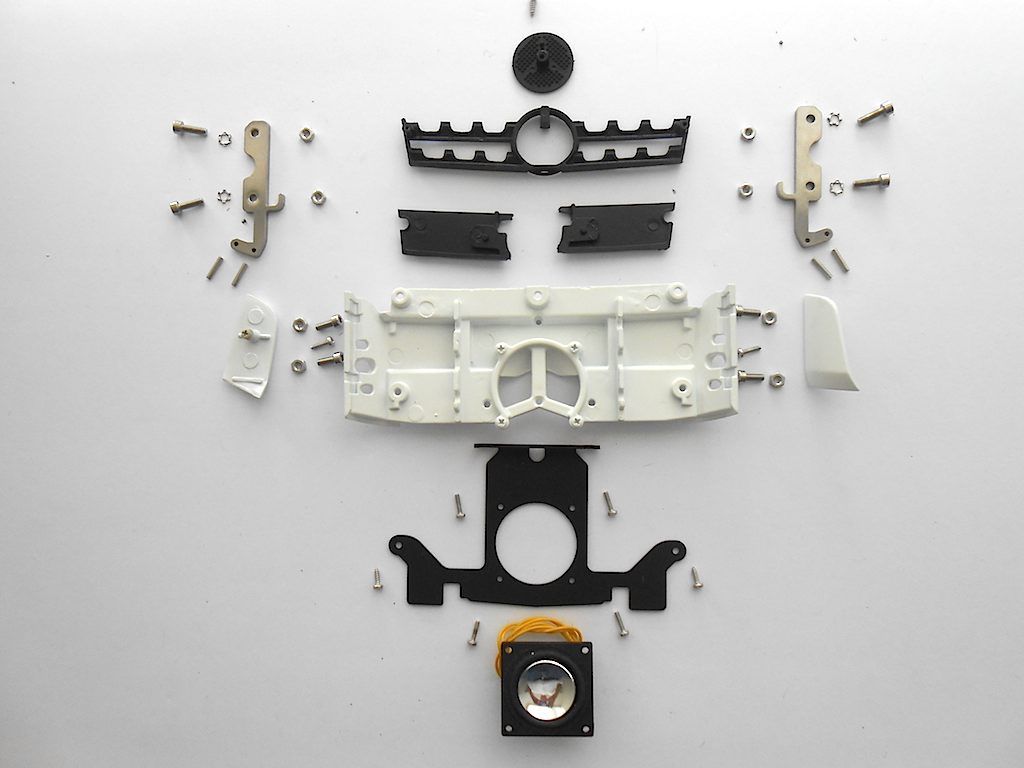

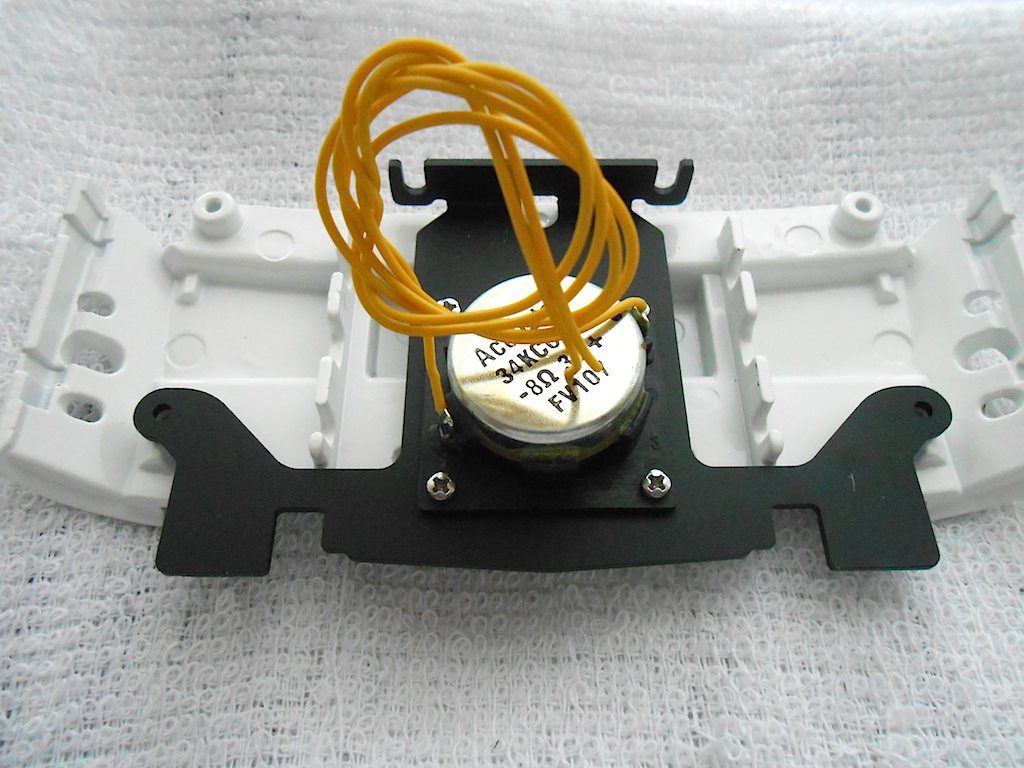

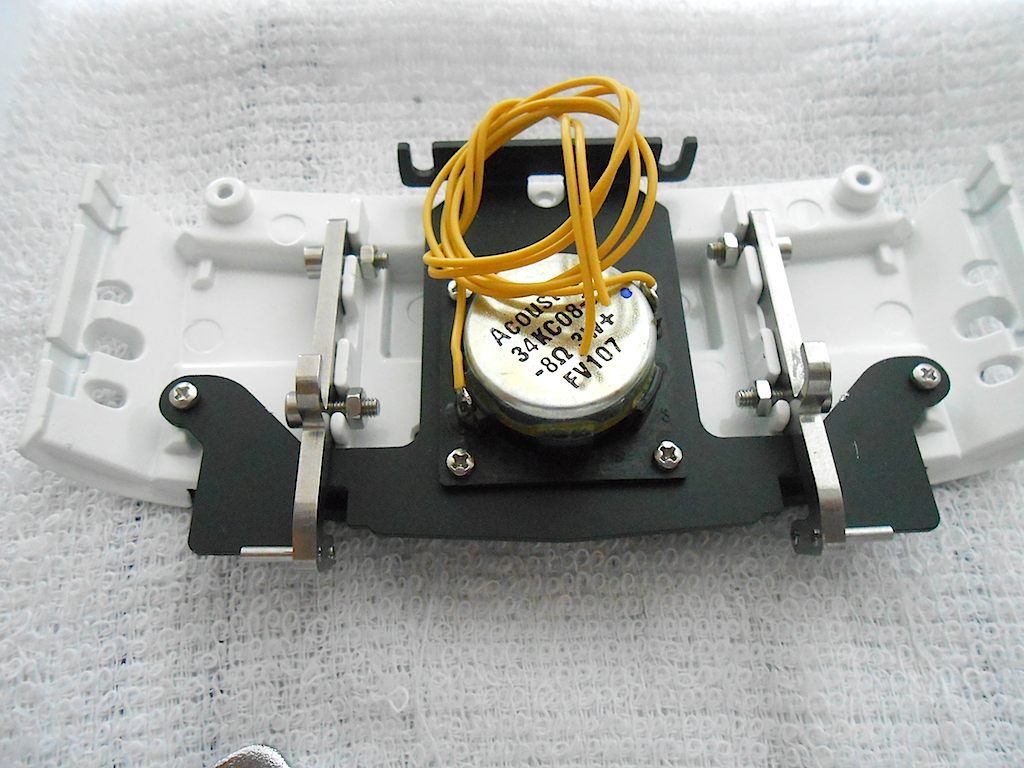

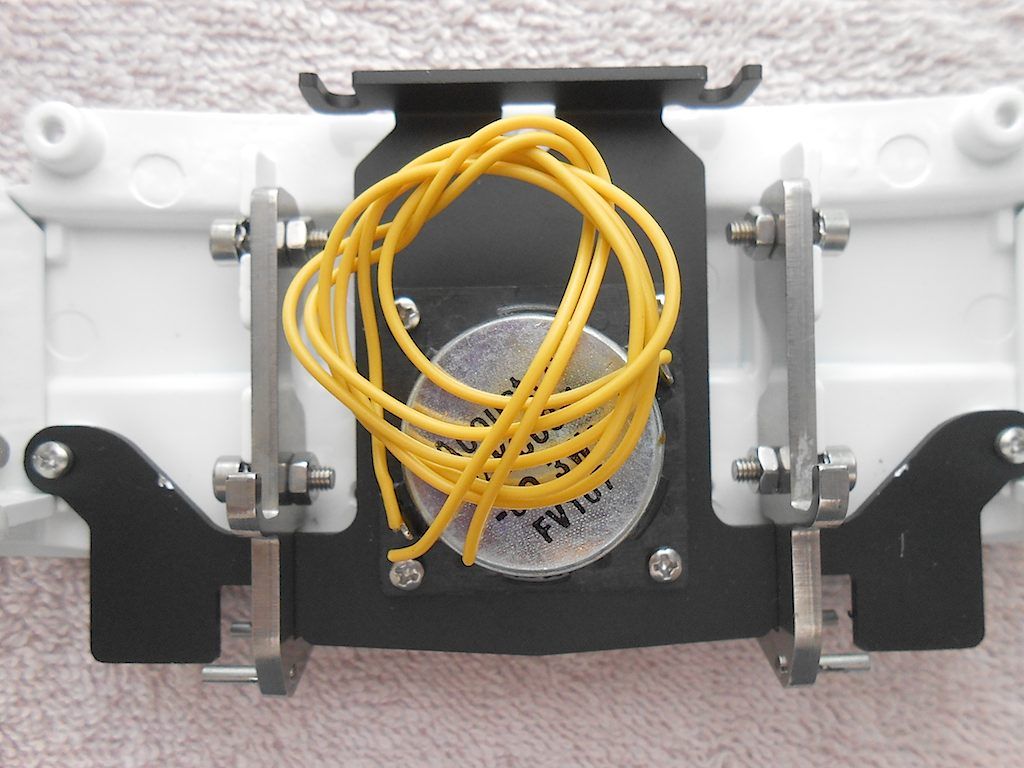

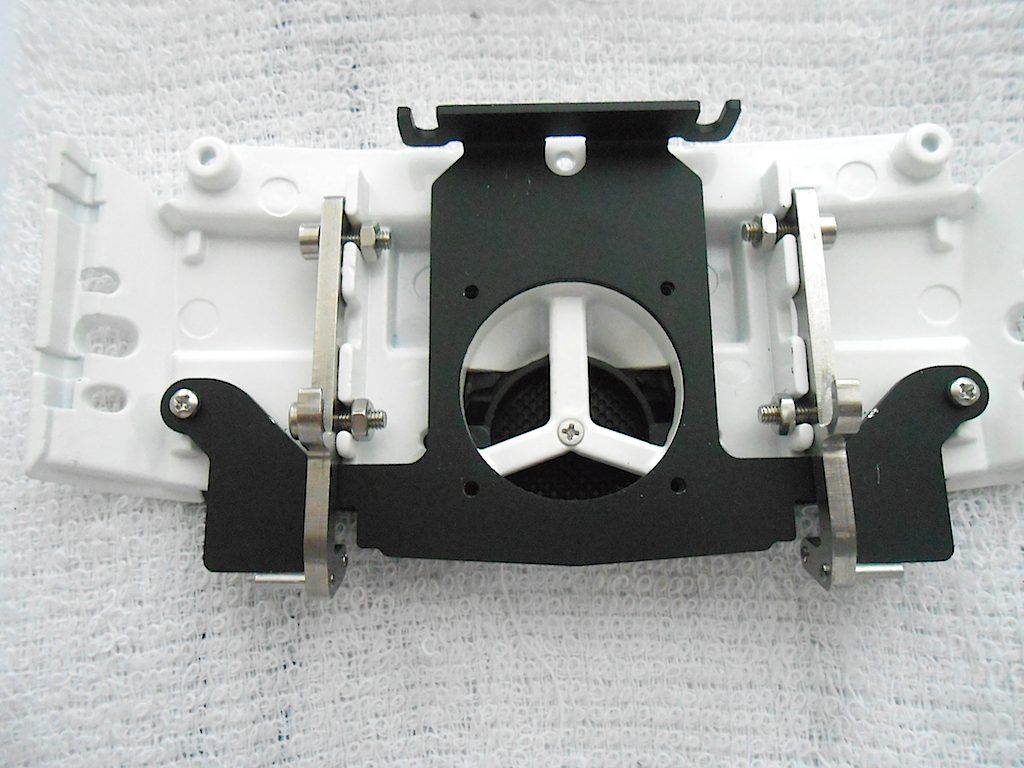

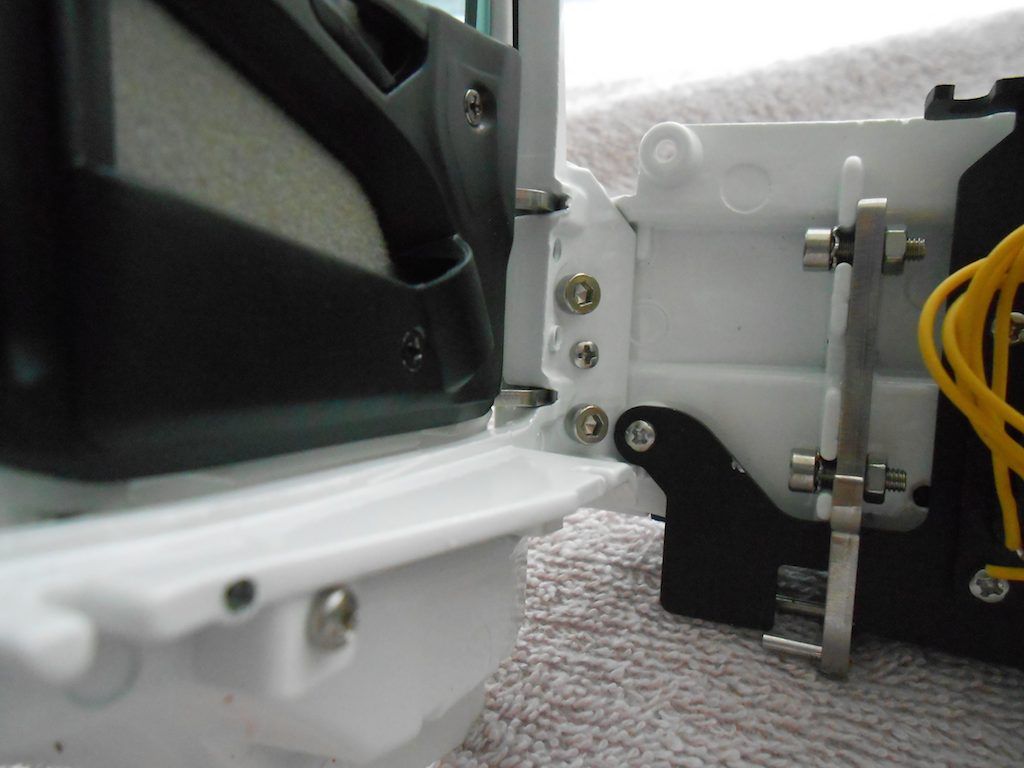

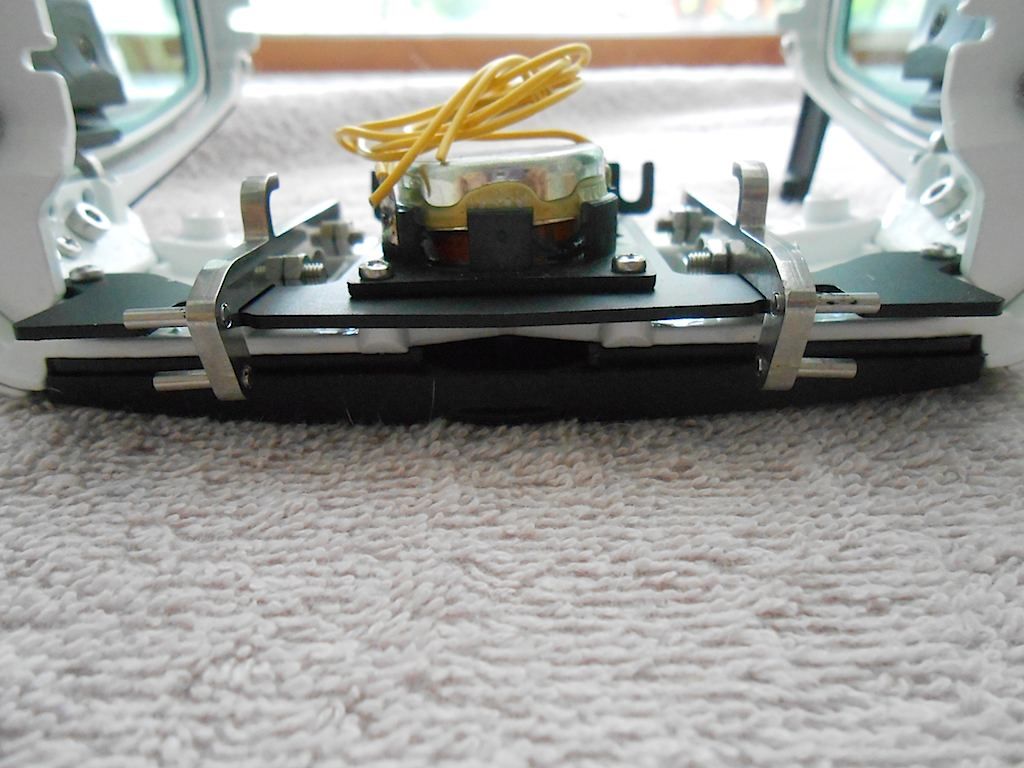

No clue what happened. Must be getting old. Next step, as said, the front of the cab. All the parts needed.  Reverse of main pieces  First I started with inserting the pins into the holders. These are the pins that go into the front locking mechanisme on the frame. (you can see the grooves at the top where they flare out a bit)  I could barely push them in the holes, so had to run a 2mm drill through them. Then needed a rather heavy hammer to drive them home. Next i installed the black metal piece and the speaker. So far so good.  Prepped the 2 stainless steel parts for installation and installed it. (forgot to take picture)  Turned over the part and put the 2 separate black plastic grill bits in place. They will be held down with the next part.  The outside part of the grill goes on top.  And gets screwed in with 2 self tapping screws from the back on the far left/right side of the black plate holding the speaker. The 2 previously installed stainless parts I had put on the wrong side of ledge they screw on too - and to think I checked a couple of times to make sure  :roll eyes: I only noticed this when I tried to fit it to the locking mechanism. :roll eyes: I only noticed this when I tried to fit it to the locking mechanism. Supposed to look like this ...  Next I wanted to attach the back of the Mercedes Star ... it screws in from the back ... so had to remove the speaker for access  Also almost used the wrong kind of screw ... Needs to be a regular countersunk one.  Installed   After sorting the stainless supports, test fitted on the front lock  And tilt works fine too  In the above picture you can see the holes that will be used to attach the sides of the cabs. The hexagonal shaped ones will hold the nuts and the middle one is for the little wind guide on the side.

__________________

Cheers, Stephan (Rakthi is the one in the avatar) |

|

#2

|

||||

|

||||

|

Now bolting the sides to the front

The two M3 Allen bolts go through from the inside to the nut on the outside. The whole thing is neatly designed. However ...  The door has a rather big gap ... Reason is why I have the red circle above. The casting is too rough at the hinges. Will need to be filed down. Apparently this is because this is one of the first batch of Arocs made. The later ones do not have this problem.  The other side same problem  Didn't yet sort it out. Just bolted it up as it was. Will sort it out tomorrow. Both sides installed   And a quick fit on the frame to get an idea. (Cab leans too far back because it's not properly supported yet)  So I guess tomorrow I will be filing away at the door frames

__________________

Cheers, Stephan (Rakthi is the one in the avatar) |

|

#3

|

||||

|

||||

|

Looking fantastic. Some epic engineering on his rig. Shows you where your money is going.

|

|

#4

|

||||

|

||||

|

While the truck does look outstanding and does have some great engineering in it, it should not have all of the design flaws in it for what you pay for the kit. Even for an early production kit, there have been too many small errors to correct for the cost. I know that I would have been pulling my hair out long ago over the many errors that have been corrected in just the chassis and now to find more in the body. This is not acceptable in my eyes.

I am not ripping the truck as it does look great, just the many overlooked design flaws which Scaleart should have addressed before marketing the truck.

__________________

LYNN |

|

#5

|

||||

|

||||

|

Quote:

|

|

#6

|

||||

|

||||

|

Hi Prop, yup, bolting this thing together I keep being impressed by the way things fit together, holes line up etc etc. Someone spend a lot of time thinking about this. When I put the front bumper on the frame I was expecting some problems because you got a lot of parts and assemblies coming together there. The only "problem" was finding the access for the Allen key.

Which brings me to tc1cat's comment ... Yes, the kit is expensive, but I do feel I have gotten value for the money. I have no idea which design flaws caught your attention. I didn't notice any. There were 4 missing hydraulic parts, a couple of wrong sized screws (easily replaced), one ball joint with a wrong thread, missing insulator on rear lights and the sliding hook part of the hydraulic mechanism that turned out to be a bit of rough machining (easily sorted). The missing parts were send out after an email. If I had found the balljoint with the wrong thread and the missing insulators at the same time, they would have included those too. So no problems there. Follow up is fantastic. The raised exhaust not fitting well. Considering this variation is sold without exhaust, it was upon me to sort it out. The raised exhaust is not meant for this model, so can't blame them for it not fitting. For the rest, everything went together as it flawlessly. Some of it required a bit more thinking than others, but most of that was because I didn't strictly follow their guidelines or misinterpreted the technical drawings. Most if not all of the mistakes in this thread are caused by my own inattention or simple stupidity like mounting the supports for the locking mechanism on the wrong side or putting things in the wrong order. The rough casting where the door hinge fits I sorted just now in about 10 minutes. Not a deal breaker for me. Neither is having to run a 2mm drill through a hole to make life easier, shortening a screw a tad or remove some paint to make something fit. All I can say is that 99.99% of the parts fit perfectly and the 0.01% is an easy fix. Just looking at the workmanship and engineering of the parts is a pleasure. Would I buy one again (given enough disposable money)? No question about it. This kit is an absolute pleasure to assemble. Now off to locate my soldering stuff ... next step is the roof and for that I need some wiring sorted out. Will post the pics of the fitting of the doors in the next update. Cheers.

__________________

Cheers, Stephan (Rakthi is the one in the avatar) |

|

#7

|

||||

|

||||

|

Stephan,

Design flaws are anything that does not fit correctly the FIRST time. Not after you modify a part or screw to get things to fit. This is something that most of us expect with a Tamiya kit due to their use of plastic parts which are known to bend during production. The needed filing of the door hinge slots is the last one you showed us. Lack of fore thought on Scalearts part to allow for paint/powdercoat thickness is a design flaw to me. Having to modify a bolt head to get a part in place is a design flaw. You have had to do this more than once if I remember correctly. You saying that most of the little things that you had to fix are not deal breakers is fine BUT you should not have to do this in a Scaleart vehicle. Scalearts attention to detail should make for a kit that goes together flawlessly. Their use of longer than necessary bolts that you need to shorten during assembly is a cost saver for them which should not be necessary for a kit of this expense. Even the most inexpensive Tamiya kit uses correct length screws and bolts. While I haven't looked at the frame rails in your latest pics, they looked like someone's test rails from 2 or 3 trucks with all of the holes in them. Hopefully, these holes have all been used by now. If not, this is a flaw for me plus it weakens the frame if not used. I know that you mentioned that these rails are used for several different trucks but give me a break. Extra holes are still unacceptable in a frame unless you remove a part from a stock frame rail. Please remember that this in my opinion and not someone elses. With all of this said- would I get a Scaleart vehicle--- YES!!! But probably not as a kit unless it was the only way to get it. Their attention to detail would be the reason. Have to win the lottery though to be able to purchase one

__________________

LYNN |

|

#8

|

||||

|

||||

|

Concidering kits like this and Capo are 10 times more intricate then your standard rc kits. The amount of deficiencies are on par. If a standard kit takes 100 steps to build and you find one problem, no one says anything. A 1000 steps for something like this and you find 10 small issues and people seem to only see the bad. Or think that for something that costs so much it should be perfect. It all seems pretty relative to me though. **** ive built most of RC4WD's offerings for instance. And the problems with their models well exceed any ive encountered building Capo's. Given the choice to have 4 or 5 run of the mill scalers from the mainstream manufacturers, or just one super scale offering from Capo or Scaleart, or Afv or whoever. I'll go with the super scale offering every time.

|

|

| Tags |

| 8x8, arocs, scaleart |

| Currently Active Users Viewing This Thread: 4 (0 members and 4 guests) | |

|

|