|

|

#341

|

|||

|

|||

|

Hey Andy looking good just one question why a John Deere sticker on a Hitachi?

__________________

Steve |

|

#342

|

|||

|

|||

|

because im cheap and bought a JD excavator and stole the cab

that will be covered in the near future. time to get the 4200 dirty, https://youtu.be/VyOc9qi3P2Y cheers andy |

|

#343

|

|||

|

|||

|

had a play with movie maker and made a quick video of some slow motion stuff, turn the sound up, amazing what you miss .

https://youtu.be/mJ7NViEBdHw cheers andy |

|

#344

|

|||

|

|||

|

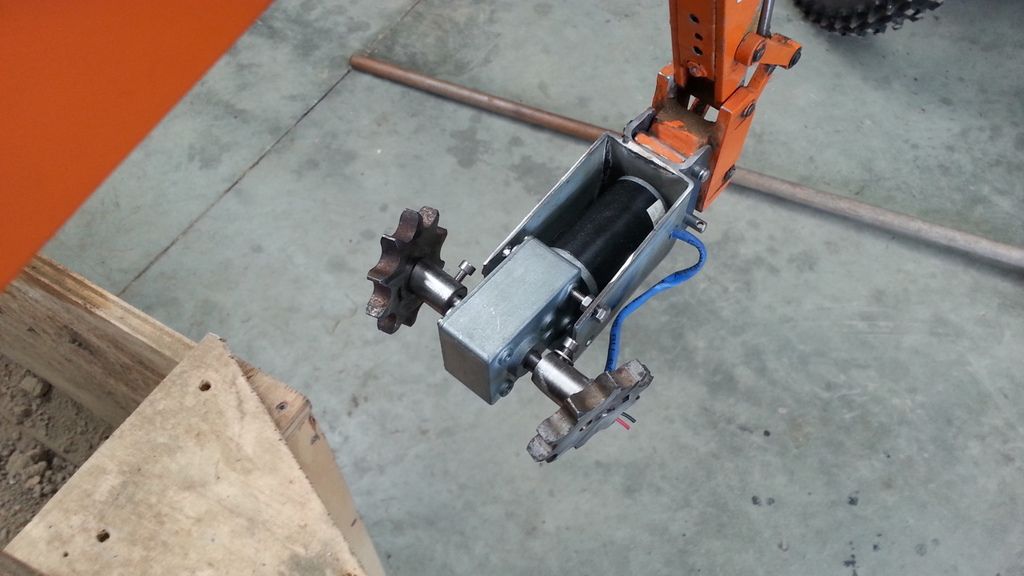

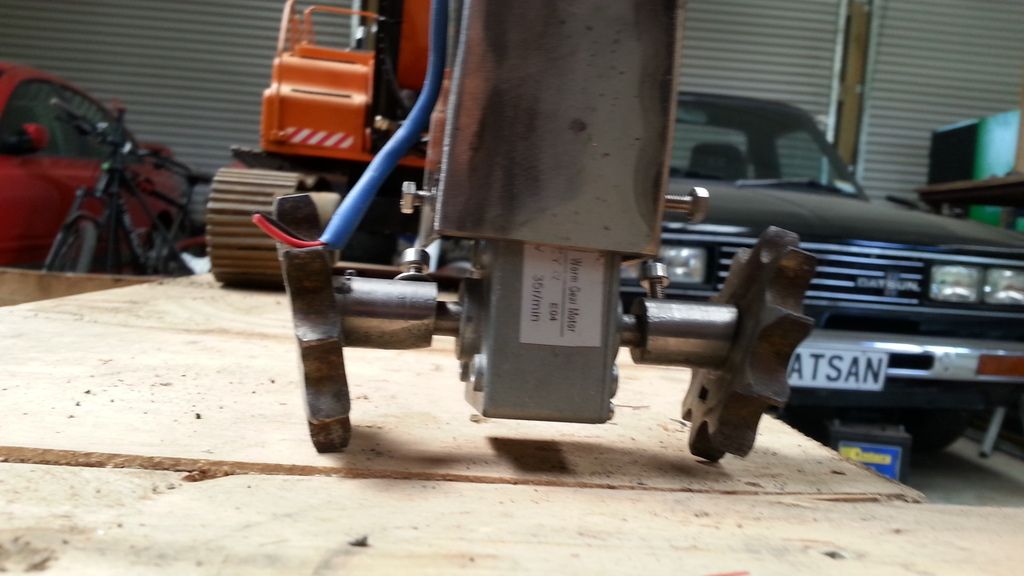

sorry Joe but I stole your idea.

been sitting on night shift for the last 4 nights, and your grinder attachment was giving me ideas on how to build the cliff road. way too hard to dig now but a grinder , now that might work. Ive robbed the drive for my roller build ( it will be too slow but its the same size). ive made a few shafts and cut on an angle and temporarily glued a sprocket on. (cant weld stainless with my mig today) but it looks like it might do the job.     cheers andy |

|

#345

|

|||

|

|||

|

just a quick test to see how strong the super glue holds before welding

https://youtu.be/k7iKFKHWg7I seems to hold for a bit cheers andy |

|

#346

|

||||

|

||||

|

DAGNABBIT ANDY

I KNEW I was over thinking this!!!   I like your idea muuuch better! much simpler, less moving parts & it looks like the Alpine cutter Neil posted a vid of.  So what's the rpm of this motor gearhead & where did you get it? To go higher rpm = less torque  What about just going with a bit bigger diameter sprocket? What about just going with a bit bigger diameter sprocket? And I really like how you attached the sprockets at an angle... Genius!  My grinder is going in the bin & I'm building one like this.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#347

|

|||

|

|||

|

yeah, watched too many cutter head videos over the last shift.

it is a 35rpm motor box at the moment, looking at probably three times the head speed for the new set up. I got the gearbox motor set up from aliexpress , but this is the one Im thinking of getting, do You recon it will be fast enough. http://www.aliexpress.com/item/DC-12...300876671.html I really didn't know if it would work , but it looks like it will work like the alpine ones on you tube and the sprockets will achieve the same thing, so we will see what happens cheers andy |

|

#348

|

||||

|

||||

|

Great! thanx for the link. Do they do PayPal? Check tomorrow to see what rpm my gizmo is running at... your current sprockets, are they 25mm diameter?

So what's happening with your jaw crusher? I thought we'd be seeing an action video long before now

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#349

|

|||

|

|||

|

no, pay pal is not an option.

get one from someone who has had lots of good feed back and all should be good. the sprockets, I think they are 15 tooth, may be 50mm diameter sprockets, the hole grinder is only about 150mm long and I thought about scale, for a bit........used what I had. If I add another sprocket on each side it will double the work load, and hope fully not the heat... |

|

#350

|

||||

|

||||

|

Found something similar on ebay, maybe it'll show up before xmas.

http://www.ebay.com/itm/321614113867

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#351

|

|||

|

|||

|

that looks the same as mine and I think the rpm's will be better.

as for the crusher , that was supposed to be the next job until I saw your grinder attachment. so you will just have to wait until im done with my grinder LOL. good thing is now that the roller has been gutted of parts for the grinder I now have all the rc parts I need to make the crusher mobile, but still have to make some adjustable motor brackets for the crusher because I cant find the right size belts. one day it will happen, but for now its summer and I really want to make a start on the cliff road with my grinder. cheers andy |

|

#352

|

|||

|

|||

|

did a little more on the grinder,

I have shortened the collars on the sprockets to get them in closer to the head, and it should work better closer together. and of course I have painted it before its finished, made a few brass brackets to hold wiring but a few more to do yet. I think I will weld sprockets on and bore a hole through the sprockets so at a later date I can just put a shaft into the hole and add another set of sprockets if I need to. pictures   cheers andy |

|

#353

|

|||

|

|||

|

more progress but a little slow.

made more brass brackets and fitted a solid line for the cables to power the grinder, and then run out of paint......   Need to do something about the wires on the bottom arm as I think they look like C@#$p. also want to widen the track base by about 15mm each side, will be easy enough to make some spacers up and longer bolts. But that's a job for tomorrow   cheers andy |

|

#354

|

|||

|

|||

|

today I finished the painting and cleaned up the cables on the bottom arm and installed two new toggle switches on the engine cover, 1 for the lights and the other for the grinder which is fused at 3amps.

also had to repaint the arms due to the new colour matched paint was different, spoke to the paint lady and she said sorry and gave me two cans for the price of one  Then I made up some spacers for the track bodies, 15mm wider on each side. this has now caused me another problem, as it only just fits on the lowboy  I need to rewire the track motors now because the cables are too short, and I found out why I blew a track esc, wires way too short and shorted together   pictures.   wider track setup  and the problem Ive created   cheers andy |

|

#355

|

|||

|

|||

|

well Im back,

had a small problem with a truck load of lightning . basically it blew all the telephone jack points off the wall, fried the big TV and all other associated electrical things on that circuit, melted the TV aerials, toasted the wifi modem ect ect. the insurance company loves me now, but at least nothing caught fire. So, with no internet or TV I headed to the shed. have been playing around with the grinder and need to make a few changes, I need bigger sprockets as the motor bottoms out too soon when grinding, also ordered a quicker motor. Will try the bigger sprockets first and see what happens. heres a quick video of the grinder at work, and a little taster of another idea I had, this needs some more internal work and more speed , but I think I can get it to work https://youtu.be/FiQGex7iBOU cheers andy |

|

#356

|

||||

|

||||

|

Andy, your video's marked private.

|

|

#357

|

|||

|

|||

|

I suppose it helps if I click on the publish button

|

|

#358

|

||||

|

||||

|

Welcome back and glad to hear all is well after the fireworks and all.

The grinder definitely needs larger diameter sprockets but I don't think you'll need to up the speed. Can you also maybe change the bottom of the drive from a flat surface to something more knife edge or tapered a bit. How much larger of sprockets are you thinking of using? The hammer,  But you need more speed there for sure. But you need more speed there for sure. . . Keep it up, looks great! |

|

#359

|

|||

|

|||

|

cheers Mario,

bigger sprockets are a must, but cant change the flat surface as that's the bottom of the gear box. I think I will look at another 10mm in diameter (60mm), I will see what they have on their shelf and its gota be cheap. and the hammer, yes there is a lot of changes needed. cheers andy |

|

#360

|

|||

|

|||

|

had to rebuild the road I destroyed with the grinder, so took a little time and had a play while thinking about different ways to do the hammer.

https://youtu.be/J8YzG0Wbsvo cheers andy |

|

| Currently Active Users Viewing This Thread: 5 (0 members and 5 guests) | |

|

|