|

|

#1321

|

||||

|

||||

|

Well, you remember last Spring when you asked me how warm & how noisy my pump reduction was? Where I had it set to exactly half speed, it was whisper quiet & the reduction was barely warm after a 5amp batt... then I tried it at about 80% speed for 8-10 minutes & I think I burnt my finger when I touch it!

It was still whisper quiet then, but the next day or two later it wasn't... and continued to get noisier with each later use. I probably don't have more than 2hrs on it since Spring b/c I just hated its erratic hydraulic movements b/c of too much flow & I like my JD850 so much more. It was still whisper quiet then, but the next day or two later it wasn't... and continued to get noisier with each later use. I probably don't have more than 2hrs on it since Spring b/c I just hated its erratic hydraulic movements b/c of too much flow & I like my JD850 so much more.  Hopefully this 30% reduction of flow will make it more fluent in motion.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#1322

|

||||

|

||||

|

Back together, I like the hydraulic speed now! Using my speed sensing tool I have the motor rpm set at 5000 & with some added channel mixing to bring it up too 6000rpm with all 3 valves activated, very smooth!!! Got lots of dirt to move with it, get it fined tuned here in the next few days.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#1323

|

||||

|

||||

|

I didn't make it through a entire batt this morning before the pump motor locked up! Just before that happened, the servos/valves were becoming twitchy - hyd movements erratic & even though the noise level ever increasing, the gear reduction unit was mildly warm.

Tear the reduction apart, gears look fine... although the wheel bearing grease I re-lubed with turned black in a hurry... what grease do you suppose I should use?  I then turned on brushless pump motor & discovered what the problem really is!!!

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#1324

|

||||

|

||||

|

Is that the motor bearing let loose? This is what bane bots reccomends for planetary gearbox use, I imagine it would be same application.

GEARBOX MUST BE GREASED Prior to use the gearbox must be greased, grease IS NOT INCLUDED and must be purchased separately. We recommend Mobil XHP 222 Special grease; however, most lithium based ball bearing grease can be used. We do not sell grease separately, it can be readily purchased from most local auto parts stores or online suppliers such as MSC, Grainger, and McMaster among others. Custom gearboxes can be supplied greased.

__________________

Always wasting money, as the wife says. To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#1325

|

||||

|

||||

|

Yes it is Coop... word this week is that Martin Kampshoff is readying another motor & reduction for me and perhaps I'll have it before xmas to get the 450 operational again.

Work on the tunnel this week has been digging the trench so I can sit closer to mouth of the tunnel... before I was 5ft further back & the shadows of the back lighting were making it difficult to see into the dimly lit tunnel... how my eye sight has changed so much in just a few yrs.   Getting the dirt built up level between the doorways in the back room... the dozer levels the dump piles to about half inch layer & the B50 with a load on does such a great job packing that I hardly leave a footprint walking on it.   This here pile of dirt directly behind tunnel, I dumped the dirt here so I didn't have to personally climb out of hole with each B50 load, this is the dirt pile the 450 should be clearing away... but I'll make it disappear with the 850 tomorrow using the pan... the pan works really well to fill in all the low spots & level out a large area with precision.    Getting to be quite a pile of rocks already & some big ones too!   All cleaned out, ready to do some more ripping & digging...   I did some measuring & rough calculating... with the tunnel just over 6ft underground & the hole with ramp & cut-in steps behind it, I've excavated about 8.2 cubic yards...

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#1326

|

||||

|

||||

|

Joe, your making great progress! How for are you from the basement wall where you are now? The other thing I would mention is that wheel bearing grease is a low rpm grease not made for high speeds due to the diameter of a car wheel. That's why at the rpm in the pump drive it's being whipped adding heat and causing pressure buildup that forces it out anywhere it can get through. At that rpm I'd recommend a good white grease or some turbine grease made for higher rpm.

Rob |

|

#1327

|

||||

|

||||

|

Youre digging yourself out of work it looks like. Have you touched your stahl excavators in the last couple years?

__________________

RIP FGD 12-19-11 To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#1328

|

||||

|

||||

|

Progress looks good Joe, I take it the room your moving the dirt into is going to remain a dirt floor?

|

|

#1329

|

||||

|

||||

|

Joe not having a dirt floor?!?! That would be like a good fishing joke I remember,, two guys go fishing, both die in car accident. One goes to heaven other to hel. One in **** is drinking a big mug of beer and a hot blond on lap. One in heaven says that sure doesn't look like ****, God replies look closer, the beer mug has a hole in bottom and the blond doesn't!!

Couldn't resist, I accept banishment back to garage I go!!

__________________

Always wasting money, as the wife says. To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#1330

|

||||

|

||||

|

looking so far joe

|

|

#1331

|

||||

|

||||

|

About half way there Rob.

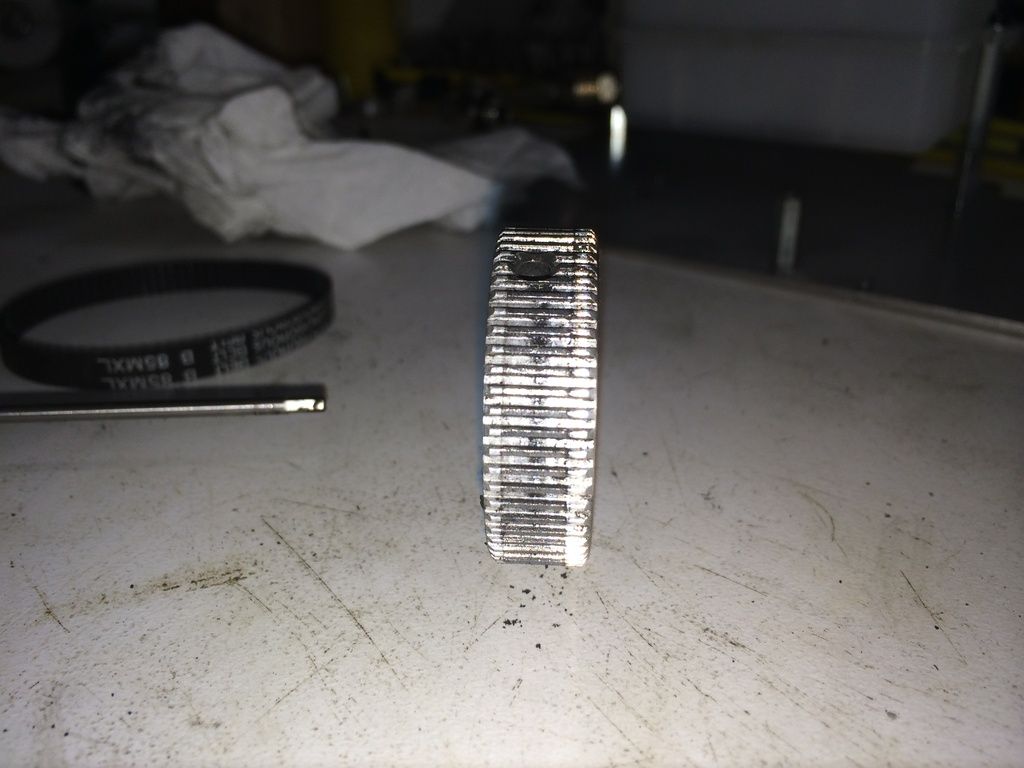

The wheel bearing grease I used is lithium based... no doubt I put too much in & it pressured up like you said... no worries though, a new motor & reduction will be here soon. The wheel bearing grease I used is lithium based... no doubt I put too much in & it pressured up like you said... no worries though, a new motor & reduction will be here soon.  T-9, the 09 Stahl I was using last winter to feed the jaw crusher in the basement, machine works at a perfect speed for that job; the 05 Stahl the boom broke can't remember when, I've stripped it down to use parts from it on other projects; the 01 Stahl still intact despite well over 1000hrs use, the 3rd set of cyls loose a tank's worth of oil per batt, but the pump & valves continued to work flawlessly, never changed a valve servo in it, it's probably 5yrs since I last turned it on. Cooper  I'm at a loss for words... wonder what else might you be cooking in the garage besides tires? I'm at a loss for words... wonder what else might you be cooking in the garage besides tires?   Not much accomplished in the LGCC quarry this week... weather here is still like Fall, been helping my neighbor tear out an old mobile trl home from his lake front lot & clean up site for a RTM to arrive next May, just incredible weather to be sweating in T shirts in December!   Late today I tore into the JD850 again, going to swap Jung pumps, what came in the JD450 kit was too much flow for that lil hoe, I think the 4003 (0,45) will be ideal for the 850 with its much larger cyls. A fresh batt with its voltage over 16, the hyd speed is where I like it, I can get a lil shake out of the bucket to jiggle the sticky dirt out.  Then in 10-15 mins it's likely less than 16v & flow slows down quite a bit. Then in 10-15 mins it's likely less than 16v & flow slows down quite a bit.   Brake Clean works like a steamer   Belt drive pulley starting to show some wear again, cogs still look good on the belt.  Clay is such a pain!!! Leaving the 850 sit in the hole the last few months, the dirt on the tracks stayed moist & the clay squeezed out between the pads. Bringing the 850 out of the hole a couple wks ago to do some wrenching on it for a day, it was just enough time for the clay to harden up some & ever since cause some binding.   Gotta change a servo on the boom valve; just recently, when ripping - working the servos continually for long periods - the boom servo starts to twitch & time out; using hoe the last couple nights to clean up pile behind tunnel - short operating intervals, no problems with servo  must be getting weak. It'll be the 1st one I've changed since new. must be getting weak. It'll be the 1st one I've changed since new.And gotta split the house from u/c again, wasn't able to take out the backlash on the swing with motor plate adjustment as much as I'd like; set screws on pinion must need changing.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#1332

|

||||

|

||||

|

Hey Joe the tunnel project is coming along nicely ..I can relate more now that i was treated to a personal tour ..seeing everything in real life gives that added advantage ..Thanks for for fine hospitality ..Wish I had more time to hang out with you ..Definitely plan to do another visit with you again soon.

|

|

#1333

|

||||

|

||||

|

It was great having you visit Lou... too bad about the dreary weather & your time crunch schedule... you're welcome back anytime. Now that you know what my farm looks like you can point it out to Greg when you fly in for your next visit.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#1334

|

||||

|

||||

|

A few of you had asked a couple months ago if frost would be a problem?... digging dirt there's no issue with the ground freezing, but the frost build up on the exposed cement ceiling whenever the temps get down to -15 to -20C for a few days, frost gets about half inch thick, then when it warms up again right away, it makes it rain in the tunnel!

... a bright sunny day yesterday & near 0, a lot of water steadily drizzling all day ... a bright sunny day yesterday & near 0, a lot of water steadily drizzling all day  ,... used a small space heater overnight & the ceiling was thankfully dry this morning. ,... used a small space heater overnight & the ceiling was thankfully dry this morning.Shot this vid a couple days ago... 5mins afterward, the 2x12 Sabertooth, one motor output operates the swing, it suddenly QUIT!  It'd been in the JD850 close to 4yrs. Don't have any more 2x12's on hand, but did have a 2x25, it's overkill, but it's working again. It'd been in the JD850 close to 4yrs. Don't have any more 2x12's on hand, but did have a 2x25, it's overkill, but it's working again.  The radio settings for the 2x12 don't transfer to the 2x25 The radio settings for the 2x12 don't transfer to the 2x25  Hope I can make the 2x25 function as smooth & precise as what the 2x12 did. Hope I can make the 2x25 function as smooth & precise as what the 2x12 did.https://youtu.be/kNP10Y2_878 And here's a vid of the Izzybilt dozer leveling the dirt piles in the adjoining room. https://youtu.be/NApC1-KCsGs

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#1335

|

||||

|

||||

|

Some serious rc excavation right there!

Love your setup Love your setup

|

|

#1336

|

||||

|

||||

|

About 12yrs in the making Brandon.

My china gear motors finally showed up today, got one that is 55rpm & the other is 160rpm. Before taking apart the V1 tunnel grinder I checked the rpm with a 12v NiMH, it's 200rpm... starting with the 160 rpm g/m, a few more hrs fab work to do yet.  Made another vid this morning placing the gopro on the cab of the B50... the 30% faster pump didn't make a dramatic difference in speed, but I do notice it's a bit faster. What's most interesting is my run time on a 5amp pack dropped about 20%, 45-50min down to 35-40min. And also, when the pump slows down to its idle speed there's this sorta chirping sound, kinda like how a muffled diesel sounds on fast idle, it doesn't make that sound when motor/pump is running full speed & the previous pump never did it at all.  https://www.youtube.com/watch?v=6n3p95e-rFo

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#1337

|

|||

|

|||

|

Quite an impressive open pit operation you got going there) I would think there are not many of these machines around seeing that number of hours on the meter ...Vario/Fumotec might should hire you as a test driver, if they don't already do

I notice that both Vario/Fumotec and Premacon chose pump motors running at 8000-9000 rpm no load, 600-900KV, relative high imo. I've not seen a Vario 850 running live, but seeing your videos I hear the pump motor kind of struggle when running against the PRV. Have you turned up the PRV setting, or is it the factory setting, and the chosen motor might be a bit under-powered? I've never been such an fan of these 'high rev' pump setups, and working at putting together my own 12V setup with a Jung HR7/4003 and a 360KV, with motor running at around 4000 rpm no load, pump 3000 rpm, which will hopefully reduce the noise, wear of bearings and transmission parts (belt) a bit compared to the german setups. Time will show) Last edited by Rimrock; 12-23-2015 at 05:29 AM. |

|

#1338

|

||||

|

||||

|

There's no shortage of power from the bl motor in the JD850, when I turn on pump it's running at an idle of (I've never measured exactly) maybe 30%. One valve might bump speed to 60-70%, two valves push motor to full speed. The belt drive is 2,5:1 reduction & I think the bl motor tops at 10,000rpm. The prv is set to 34bar. With 18 & 22mm cyl bores, this JD850 needs a big fast turning pump.

The Fumotec - Premacon bl motor/pumps you're referring to is supplied by Martin Kampshoff, he uses a smaller (diameter wise) bl motor, about 700kv with I assume his design planetary reduction 4,5:1 on a Jung 4003 pump. I started out with that 4003 pump in my Fumotec hoe, motor speed accurately metered to 4500rpm, I found the hyd flow to be way too fast for 14mm cyl bores. Last month I changed pumps to a 4002 (0,30ml/rev) & with the speed set too 5000rpm idle speed, plus radio mix - all 3 valves activated will make motor speed 5800rpm max (330-385ml/min). I didn't get half hour run time with that setup before motor locked up with blown bearings, but I was liking the slower flow for much smoother fluent motion. It's that same 4003 pump that is now in the JD850. What I've learned from this Fumotec hoe, as well as the china hoe, running any brushless motor continually below 50% of its nominal speed, it's accuracy in maintaining speed while under load is erractic. I used a 30amp E-Flite esc in the Fumotec hoe. I think the JD850 uses a 30amp E-Flite as well. I get great service from Frank Preisendoerfer, and lots of great insight too for other personal projects. I don't waste Frank's time dickering over pennies for cheapest price and Frank don't waste my time getting what I need! Badda Boom Badda Bing Done!!!

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#1339

|

|||

|

|||

|

**** Joe, do you run your 850 at 34 bar? I think mine is set to 25 or less!

And Im with you, Frank is one helpful, service minded guy! |

|

#1340

|

||||

|

||||

|

Yep!!! When I changed pumps, the 1st thing I checked was pressure & the higher flow bumped the pressure beyond the 40bar mark. I turned the prv screw back nearly a full turn to get it down to 34Bar again. I set the pressure with a full charged 4s batt & pump running at max speed so for sure it doesn't ever exceed that.

The stick cyl weeps a wee little bit, barely detectable when working the stick hard at ripping, but other than that, no leaks, no blown hoses... luving it!!!   Such high pressure, the end of the boom where the stick pivots, it's wearing... I had the stick off this fall & debated whether to pull the boom off to machine the holes for brass bushes... my mill aint big enough for such a huge part & what really scares me is any sort chatter - vibration while milling the 5mm steel plates would shatter the resin encased boom!!! Then I be really SKREWED!!!  cause I asked Frank beforehand if Vario had any booms in inventory, he didn't think so. cause I asked Frank beforehand if Vario had any booms in inventory, he didn't think so.  What I ended up doing was machining a new steel pivot pin, the left side bigger diameter to fit the slightly oblong hole snug; the right side is near perfect yet. I don't think they have sold any Vario hoes for a couple yrs now, it's size & weight makes it unpopular... I asked Frank a couple yrs ago how many Varios in the world - he thought it was just over 50... I think I'm the only one in Canada, there's 6 in the USA that I know of... too bad, it's such an awesome perfectly balanced weight to power model.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

| Currently Active Users Viewing This Thread: 22 (0 members and 22 guests) | |

|

|