|

|

|||||||

| Truck Building Tech Covers mechanical and electrical components for truck modeling |

|

|

|

Thread Tools | Display Modes |

|

|

|

#1

|

||||

|

||||

|

Joe we put 5 55turn motors on my dyno and they ranged from 4800-5900 rpm. Instead of running the dyno with a 12 power supply and regulating the dyno to 7.2v we ran the dyno with 2 of my good NiMH 7.2v batteries which give a better reading. We ran all 5 motors on one battery and then did it again with the other battery. The 12v power supply is fine to break in a motor but using a battery pack will give you a better reading of the motor this is how we used to do it for our race cars.

__________________

AKA "00" Biddle RIP FreddyGearDrive 2-12-59/12-19-11 |

|

#2

|

||||

|

||||

|

Quote:

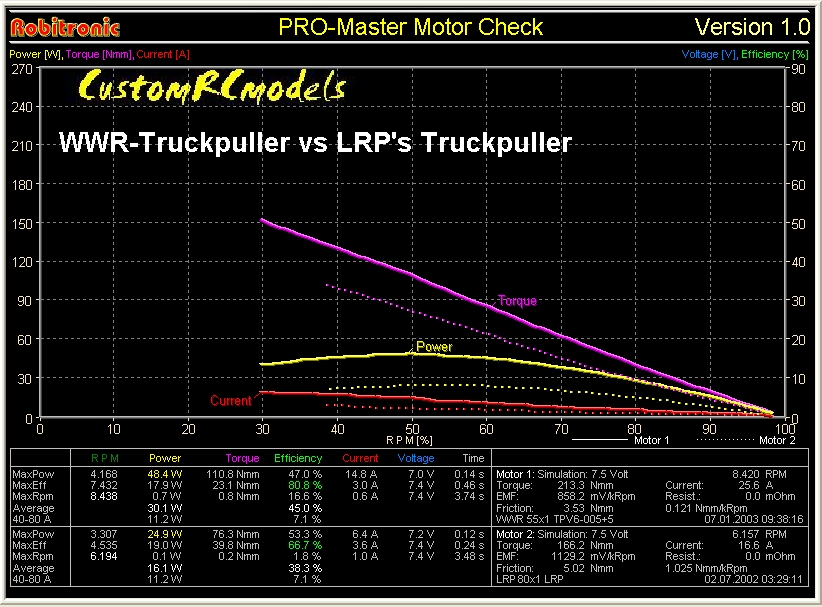

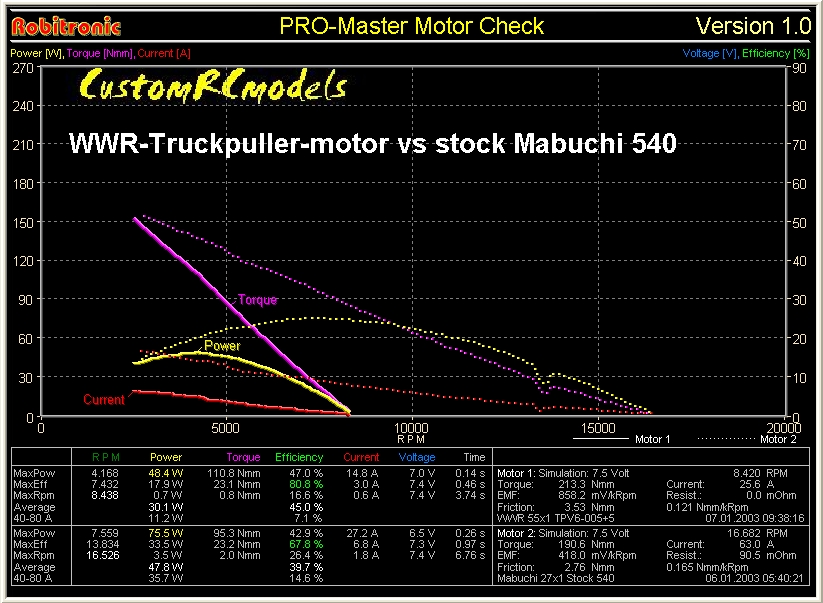

What dyno do you use ? A typical 55 turn motor should have around 8000 rpm’s with zero timing . Your readings look like readings you get on a dyno with a internal stabilized 5 volt supply , no matter what you connect to it . Here are my test-results from 2002 Comparing my own WWR-Truckpuller vs the LRP Truckpuller ( 55 turn vs 80 turn )  and here my WWR-Truckpuller vs stock Mabuchi 540 ( 55 turn vs 27 turn )  here you can read my write up from back then : http://www.customrcmodels.com/id442.htm

__________________

(Wild)-Willy CustomRCmodels |

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|