|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

|

Thread Tools | Display Modes |

|

|

|

#1

|

||||

|

||||

|

WOW!! Your work is always top notch. Silver soldering is an art in itself. Not sure a resistance iron will work with the brass frame being so much thicker than the cross bracing. Torch is going to be just as challenging due to the size difference. Some sort of heat sinks or the heat blocking putty may be your best bet.

Took me awhile to get the hang of soldering on my Studebaker. The grill alone took over a hour to solder together and I made a jig first. Glad I only have to do about 8 or 9 more solder joints and it will be back to machining again. Would really like to see your work in person. Course I would probably just stare and drool over it.  I do a lot of that at the NAMES show each year. I do a lot of that at the NAMES show each year.

|

|

#2

|

||||

|

||||

|

Quote:

Why don't you come to York in January with some of us other guys and bring the Studebaker. Work in progress are always welcome. I want to look that truck over. I have resistance power supply's up to 2500W I picked them up when they were cheap enough. I hope to find a use for them just need the proper jaws maybe. |

|

#3

|

||||

|

||||

|

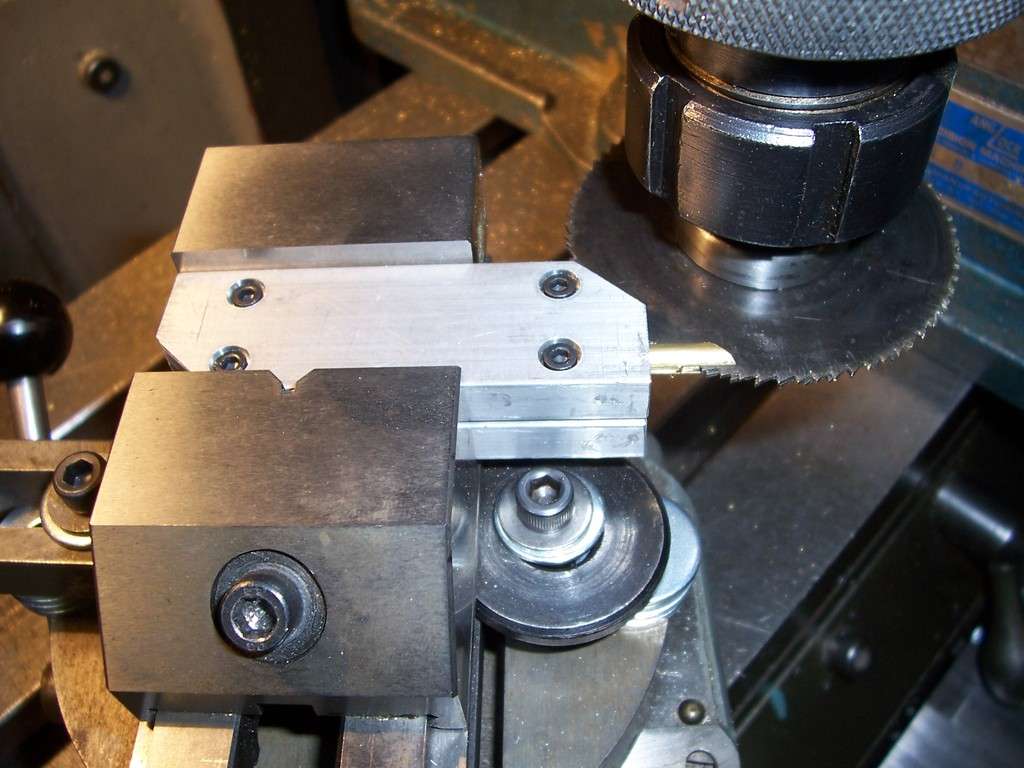

I spent 3hrs last night trying to mill these tighter angled pieces. I got one almost right. Today I had to make a small vee block fixture to hold the tube further out of the vice so the slitting saw won't hit the vice. I also found the problem with the narrow groove Tom. The saw I was using measured .060'' and my tee is .063'' so I stacked up two saws that measure .064'' wide.

|

|

| Currently Active Users Viewing This Thread: 2 (0 members and 2 guests) | |

|

|