|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

|

Thread Tools | Display Modes |

|

#101

|

||||

|

||||

|

Oh

Have a good one Kornel

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#102

|

||||

|

||||

|

Quote:

Merry Christmas Buddy! |

|

#103

|

||||

|

||||

|

"Nuttier the better" Yup.....more entertaining that way!! As long as it doesn't get "one flew over the cuckoo's nest" nutty we should be good!!

|

|

#104

|

|||

|

|||

|

Quote:

|

|

#105

|

||||

|

||||

|

Quote:

|

|

#106

|

||||

|

||||

|

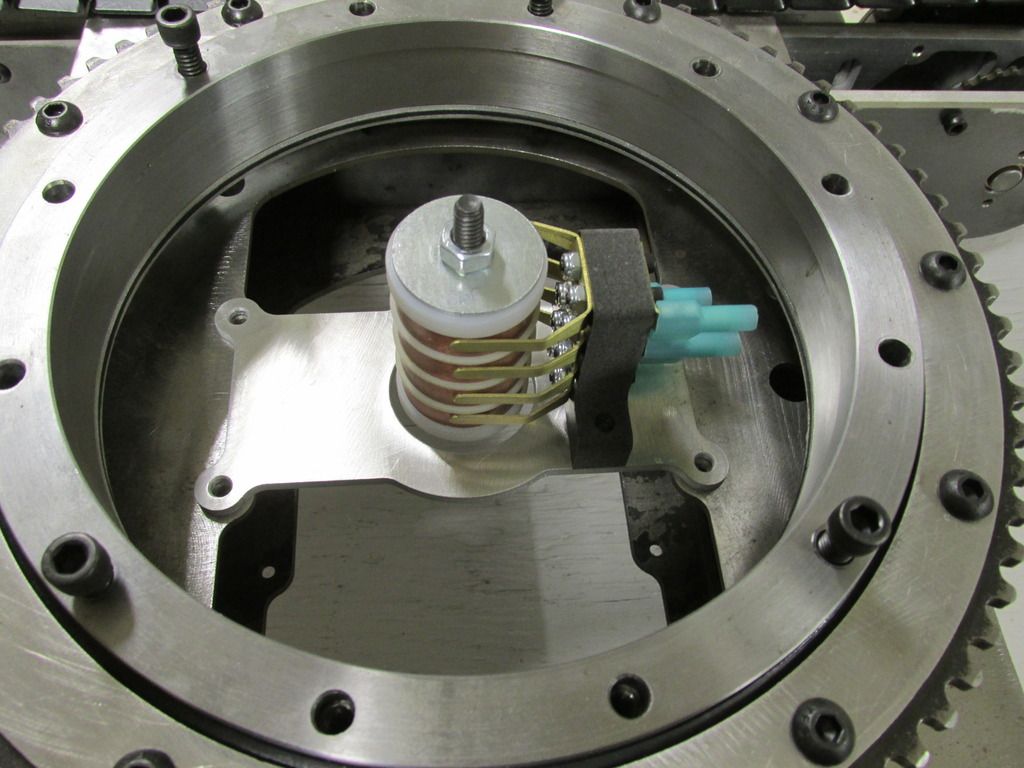

This is my simple attempt at building a slip ring....hope it works!!??

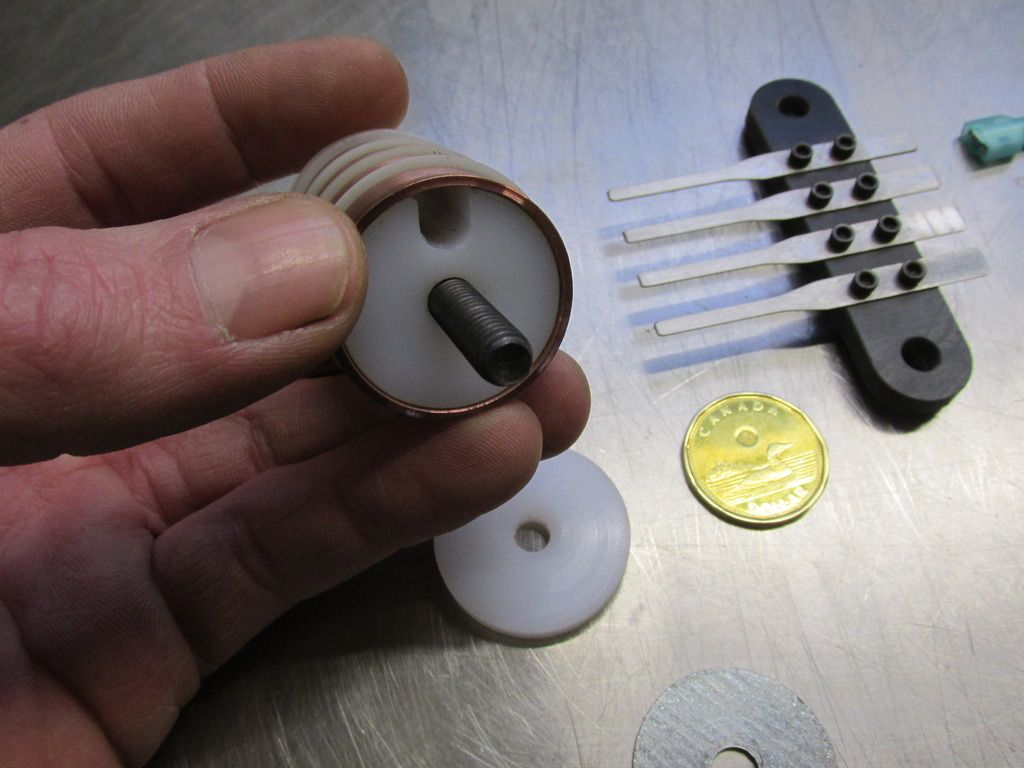

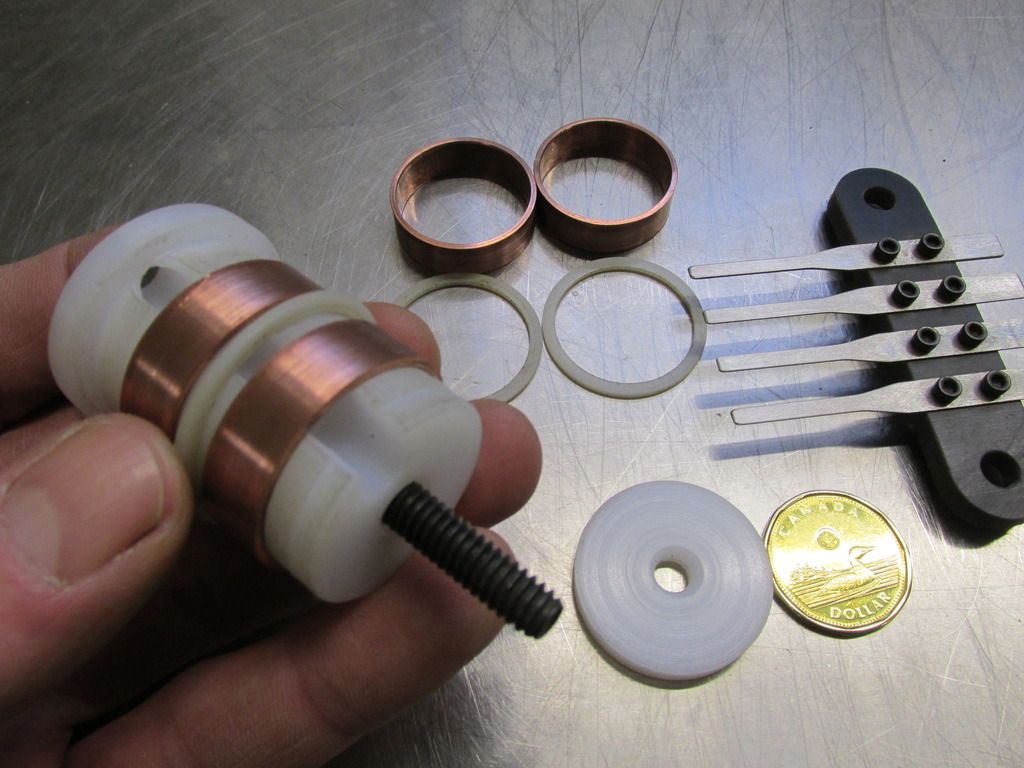

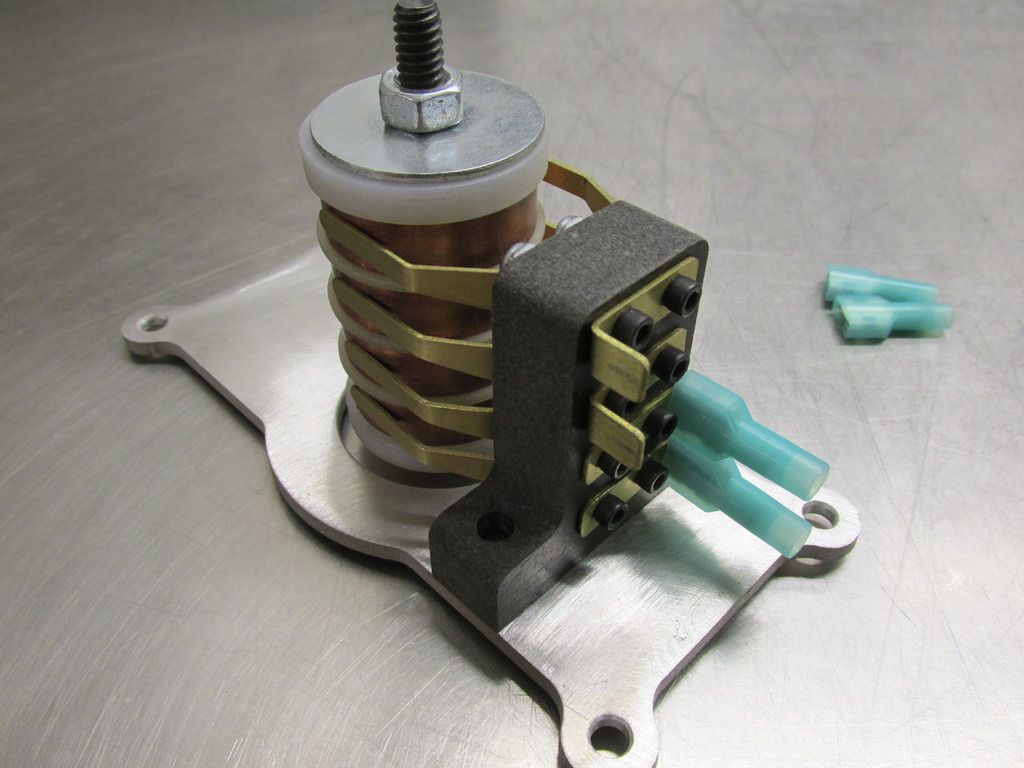

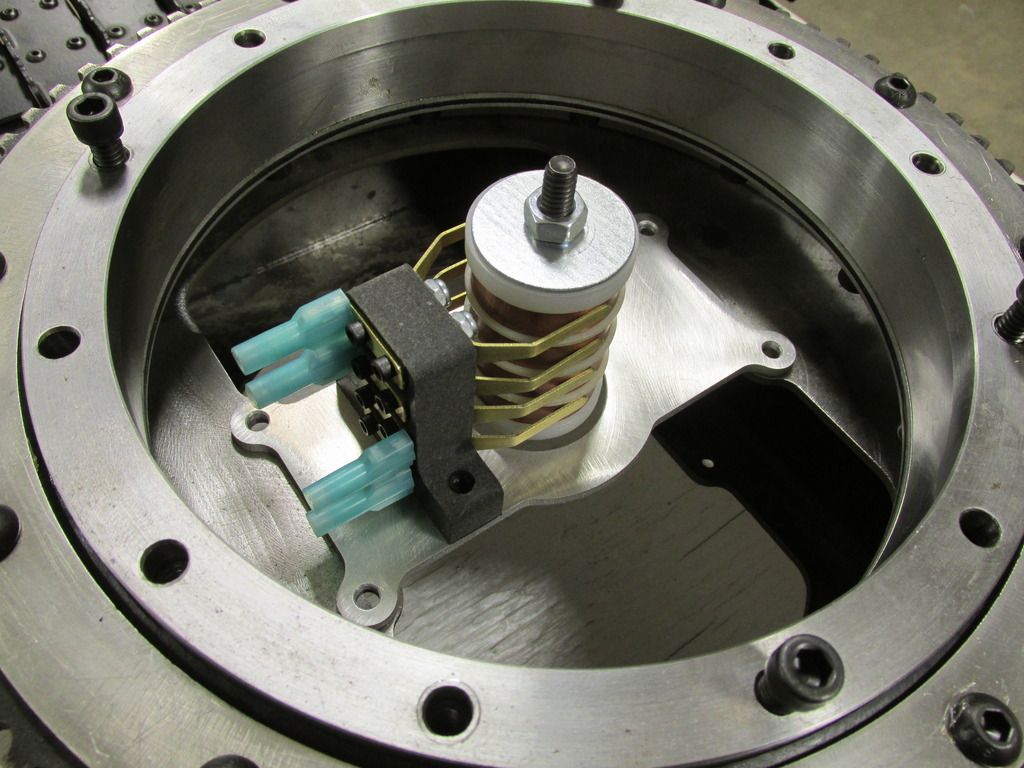

Used copper pipe for the rings, one wire will get soldered to the inside of each ring and exit out the slot in the center post. Originally I was only going to use one contact bar/finger on each ring, the new idea has two points of contact on each ring which should work better and the tension on the rings can be adjusted by simply bending the brass contactor arms closer together if needed. [IMG]  [IMG]  [IMG]  [IMG]  The center post will be mounted directly to the bottom of the body floor and rotate with the house, the stationary contact finger assembly is mounted to the center track frame. Each track drive motor will be connected to the brass leads on the assembly. Really hope this works!! Not sure how long the copper will last against the brass fingers, and I don't really like the idea of two different metals being used on this but the copper pipe was the easiest way to build it and would be easy to replace if it wears out to fast [IMG]  [IMG]

|

|

#107

|

||||

|

||||

|

What a beautiful setup for a slip ring. Just put a generous coating of dielectric grease on the copper rings to stop pitting and it will last forever!! And it looks to me like that Alberta loonie is shrinking smaller with every picture, go Justin!!!!!

Rob |

|

#108

|

||||

|

||||

|

I was going to suggest the same thing as Rob... the slip ring in my JD850 is somewhat similar to yours Kornel with brass contacts, before adding the dielectric grease the friction created a black soot on the contacts creating a loss of electric connection... not a moments trouble since 4yrs ago.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#109

|

||||

|

||||

|

That is a very helpful suggestion guys!! Thanks!!! Difinetly going to do that when I get it wired up for the first test, still need to order the gear/box motors and finish a number of things yet before it's ready for a test run....Thanks again!!

KP |

|

#110

|

||||

|

||||

|

Nice slipring!

|

|

#111

|

||||

|

||||

|

Every time i come on here i learn something ...Break out the popcorn ..think this tread deserves that ...I dont see anything wrong with that slip ring ..thanks for sharing ...good to see you you back on this build

|

|

#112

|

||||

|

||||

|

Quote:

KP |

|

#113

|

||||

|

||||

|

|

|

#114

|

||||

|

||||

|

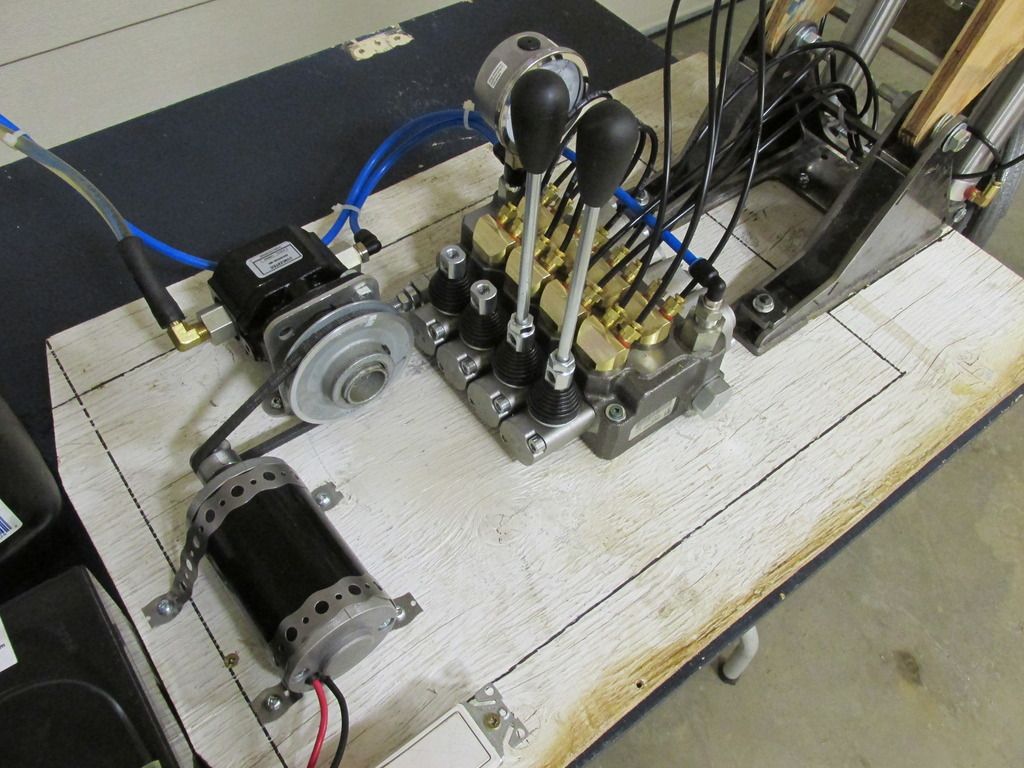

Did some more "high tech" testing of the hydraulics....turns out it does work but not as planned...lol...the open center valve is not the best for running more than one function at a time, live and learn, need to convert it to a closed center which will mean the PRV will be bypassing all the time when the controls are in neutral instead of free flow back to tank when using an open center valve.

Started testing with 20 lbs and then added another 20lbs to see what it would do with the 40 lbs....the extra weight made little to no change in cycle times or pressure [IMG]  After running it with the 40lbs I noticed the 1/4" threaded rod was bending under the load, so went back to using only 20lbs for the "wire and wood" testing...lol [IMG]  The motor and belt drive seems to work well, using a small adjustable pulley on the pump so the RPM of the pump can be changed a bit while using the same input RPM of the motor [IMG]

|

|

#115

|

||||

|

||||

|

That's a shame about the valve bank but I'm sure you will get it sorted out. Looks like a good simple setup. I say just paint the plywood and get digging.lol

|

|

#116

|

||||

|

||||

|

So what pressure are you currently running at?

So you can't feather two valves together at all for simultaneous movement? I don't fully understand the open/closed concept, but I'm pretty sure these german made rotary valves are open center, as there is two return lines off one side of the valve; one goes through prv & the other direct to tank. Precise movement of the tx & I can get all 3 valves to work together.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#117

|

||||

|

||||

|

With all valves in neutral and flowing back to tank what kind of pressure is in the system? I'm just wondering, some systems use a slow return check valve for the oil returning to tank. It keeps the valve in a more charged and ready state. Using a flow control you could restrict return flow to a point and not generate excessive heat. Let's say you have 50psi in a free flow state right now, using the flow control you could increase that to maybe 75 or 100 psi and see if the functions improve? Also, your prv would need its own dedicated return line to tank and not tee into the valve bank return line.

It may be something to experiment with before going through the hassle of converting to closed centre system? |

|

#118

|

||||

|

||||

|

Quote:

Yes two valves can be used together but the speed of both functions changes as well as the pressure, I can understand the pressure change but flow should remain constant no matter what the pressure is.....a positive displacement pump (gear pump) that delivers say 2cc per revolution should always deliver that amount of oil no matter what load is on the system,what will change is the pressure and the speed the oil needs to travel through the system.... In an open center valve all the flow from the pump is allowed to flow "freely" back to the tank when the spool valves are in the neutral or center position...so my thinking was that it would be a good way of eliminating the use of an ESC on the pump to gain some battery run time, the pump would always be running at a constant RPM and would take less power to just keep moving the oil in the system unrestricted when no function is being used, instead of always having a load on the pump and motor when using a closed center valve that needs a way of allowing the flow to get back to the tank using some type of unloading valve....but a closed center valve system always maintains a constant pressure in the system which is set buy the unloader valve or PRV, the open center has almost zero pressure in the neutral position because there simply is no load or restrictions in the system which is good in one way and bad in other ways..... |

|

#119

|

||||

|

||||

|

Quote:

From what I understand changing this valve to a closed center should be easy......need to change out one fitting.....the closed center simply uses a plug to block the center port flow to the return line port....when the plug is installed and the controls are in neutral (center position) all the flow must pass through the PRV and back to tank. I'm sure you already know much more than I do about hydraulic systems and don't need to learn anything from what I am sharing as I slowly learn more on the subject, I'm sharing this more for others who might also be interested in learning more on this subject. We can all be thankful and learn from the skills and knowledge shared here on this forum....like Joe says "the more you share, the more you get" So....Thanks guys for sharing what you know with those of us that don't !! |

|

#120

|

||||

|

||||

|

The hydraulic stuff can get confusing very quickly. Yes, a fixed displacement pump will deliver same volume for same pump speed, but if divided between circuits, each circuit gets only a part of that volume, so each function will be slower than each individually. Also, for a given valve opening, oil volume is directly related to pressure on that circuit. If using two circuits at once and both valves are opened the same amount, the circuit with the least resistance (and lower required pressure to move it) will move first. Only when that circuit bottoms out or it's valve is closed, will the other (higher required pressure) function move. Throttling or feathering the two valves during operation is the only way to compensate so both functions can move simultaneously while operating at different circuit pressures. Pressure-compensated (and usually with variable displacement pumps) take care of this for operators, but are much more complicated systems. Yes, the open center system does reduce heat and horsepower needed when in neutral. But having some "standby" pressure, as Mario stated, does give quicker response when activating. Also, open center may allow a function to drop a bit when first pressurizing a circuit - I don't think our model circuits have load-check valves to prevent this.

Ken

__________________

Big iron is awesome! |

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|