|

|

#101

|

||||

|

||||

|

Steve , I would use the torch . if you have it all clamped in the jig ready to solder , you can heat a muti joint area and solder at once .

IHSteve

__________________

RIP FreddyGearDrive 2-12-59/12-19-11 To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#102

|

|||

|

|||

|

Yeah steve-I noticed the gaps but couldn't tell how big they are. The silver will fill in some gaps. I have heard of the resistance soldering but never seen it used. That may be the way to go. Using the torch ,the thick angles will take a lot of heat and it may be too much for the thin-wall tubing. I'm sure you will figure it out.

Last edited by modelman; 10-05-2010 at 01:46 PM. Reason: adding something |

|

#103

|

||||

|

||||

|

WOW!! Your work is always top notch. Silver soldering is an art in itself. Not sure a resistance iron will work with the brass frame being so much thicker than the cross bracing. Torch is going to be just as challenging due to the size difference. Some sort of heat sinks or the heat blocking putty may be your best bet.

Took me awhile to get the hang of soldering on my Studebaker. The grill alone took over a hour to solder together and I made a jig first. Glad I only have to do about 8 or 9 more solder joints and it will be back to machining again. Would really like to see your work in person. Course I would probably just stare and drool over it.  I do a lot of that at the NAMES show each year. I do a lot of that at the NAMES show each year.

|

|

#104

|

||||

|

||||

|

Quote:

Why don't you come to York in January with some of us other guys and bring the Studebaker. Work in progress are always welcome. I want to look that truck over. I have resistance power supply's up to 2500W I picked them up when they were cheap enough. I hope to find a use for them just need the proper jaws maybe. |

|

#105

|

||||

|

||||

|

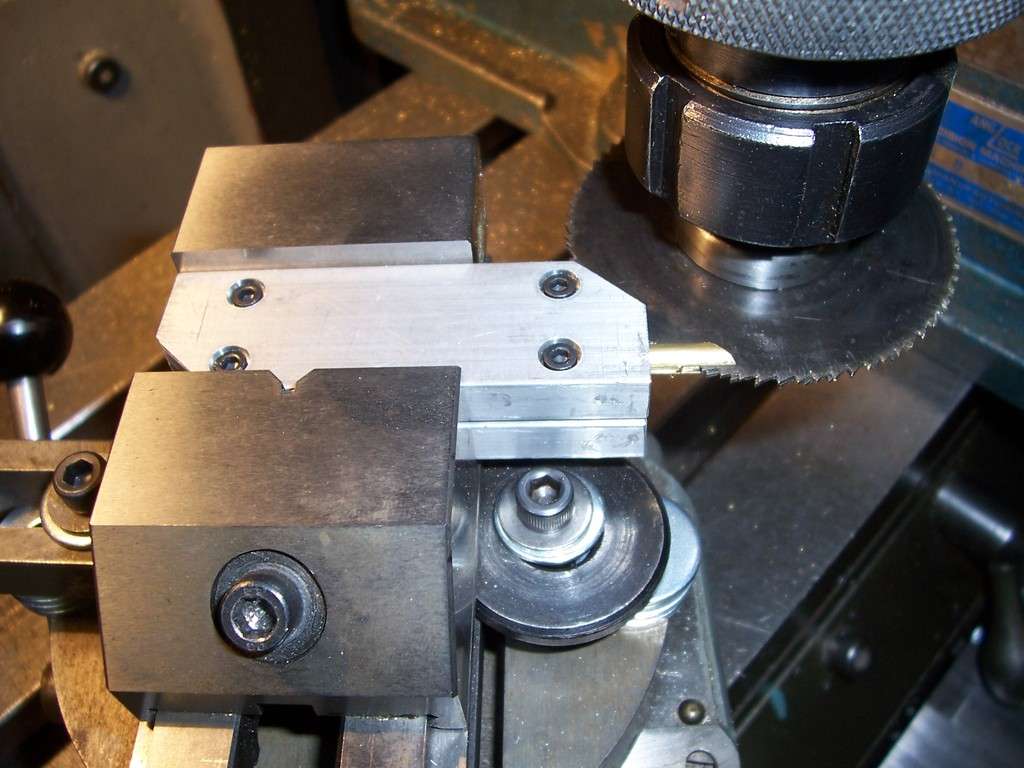

I spent 3hrs last night trying to mill these tighter angled pieces. I got one almost right. Today I had to make a small vee block fixture to hold the tube further out of the vice so the slitting saw won't hit the vice. I also found the problem with the narrow groove Tom. The saw I was using measured .060'' and my tee is .063'' so I stacked up two saws that measure .064'' wide.

|

|

#106

|

||||

|

||||

|

Nice setup!

Kerst |

|

#107

|

|||

|

|||

|

Nice set-up steve-seems like I spend half my time trying to build something to hold something like you did. I guess that's how it goes. Are the saws carbide? I tried slitting tubing with a dremel saw a few years back and trashed the tubing and the saw.

|

|

#108

|

|||

|

|||

|

Looks like just standard High speed steel jewelers saws. I've been using a .0625" by 6" saw on my manual mill for the last 2 days as well, great fun.

__________________

Jeff |

|

#109

|

||||

|

||||

|

Yes they're just high speed steel (two stacked) but a little dull but work fine. The new setup works great now that I can push the tube closer to the fixture and I can cut into it rather than the toolmakers vice

I managed to get three more mitered and notched this evening (about 45min). Maybe tomorrow I'll knock a few more out. This run of pieces has 2 sets of 20pcs. I'm having some trouble dialing in the different angles, their not 45deg their 43.8 46.6 etc. I managed to get three more mitered and notched this evening (about 45min). Maybe tomorrow I'll knock a few more out. This run of pieces has 2 sets of 20pcs. I'm having some trouble dialing in the different angles, their not 45deg their 43.8 46.6 etc.

|

|

#110

|

|||

|

|||

|

You've got CNC, why angle the vise? Just make the cut angled. Should be real easy if your machine will take a polar coordinate move. Program for your start and end point, and just change the Polar angle for each tube. If no polar then just some quick math to determine new endpoint for different angles

Or is there something I'm missing???

__________________

Jeff |

|

#111

|

||||

|

||||

|

I can do it quicker manually since there's only two pieces each. First I'd have to locate each one for length possibly rough cut the angle on the bandsaw so I wouldn't have to take several small cuts and do a program for each set. I've done it before on some of the other pieces but it's not worth it for the hundreds of different sized pieces. If I had a tiny chop saw I could cut the angles but I would still have to orient them in the vee fixture properly for notching. I would definitely do the CNC set up if all of them were the same.

|

|

#112

|

|||

|

|||

|

Ok, that makes sense. I guess for some reason I was thinking a bunch of them were similar.

__________________

Jeff |

|

#113

|

|||

|

|||

|

Steve-any progress on the boom?

|

|

#114

|

||||

|

||||

|

That's funny I was going to post at lunch but we rode up to TACO SMELL first

Been busy this past week but found an hour here and there to make some tubes. Every pair is a different length,and angles are different each end because; the tube's edge goes from one side to the other side of the centerline. Been busy this past week but found an hour here and there to make some tubes. Every pair is a different length,and angles are different each end because; the tube's edge goes from one side to the other side of the centerline.Well, I got enough pieces (40) for both sides of the bottom 45'' section done. Now I need to mill the "T" chords to proper length and drill all the slice plate holes. Then on to soldering

|

|

#115

|

|||

|

|||

|

Looking good!

__________________

Jeff |

|

#116

|

||||

|

||||

|

That looks good, Steve. How long is the boom going to be or did I miss that?

__________________

Joe |

|

#117

|

||||

|

||||

|

About 122.5''

|

|

#118

|

|||

|

|||

|

Good timing huh! Looks perfect. Nice joints!

|

|

#119

|

||||

|

||||

|

Man, that thing is going to be a beast. What are you using for cable? or (line)

__________________

Joe |

|

#120

|

||||

|

||||

|

Nice work Steve!

Brian |

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|