|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

|

Thread Tools | Display Modes |

|

#41

|

|||

|

|||

|

Quote:

They are made by a German company named Maedler, but they don't sell online, you have to find a dealer to buy through. |

|

#42

|

|||

|

|||

|

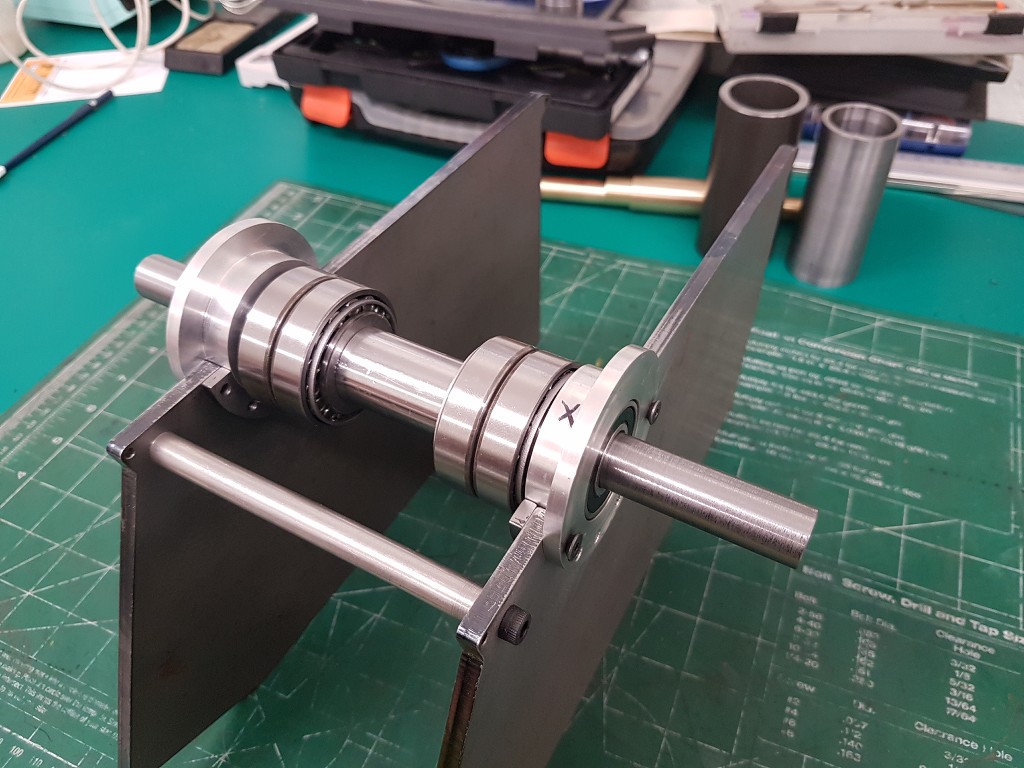

Oh well, I have scrapped the brass axle and roller bearings, the old one still seems to hold up for the new owner but I just wanted to make the axle out of steel and get the tapered bearings as someone here suggested!

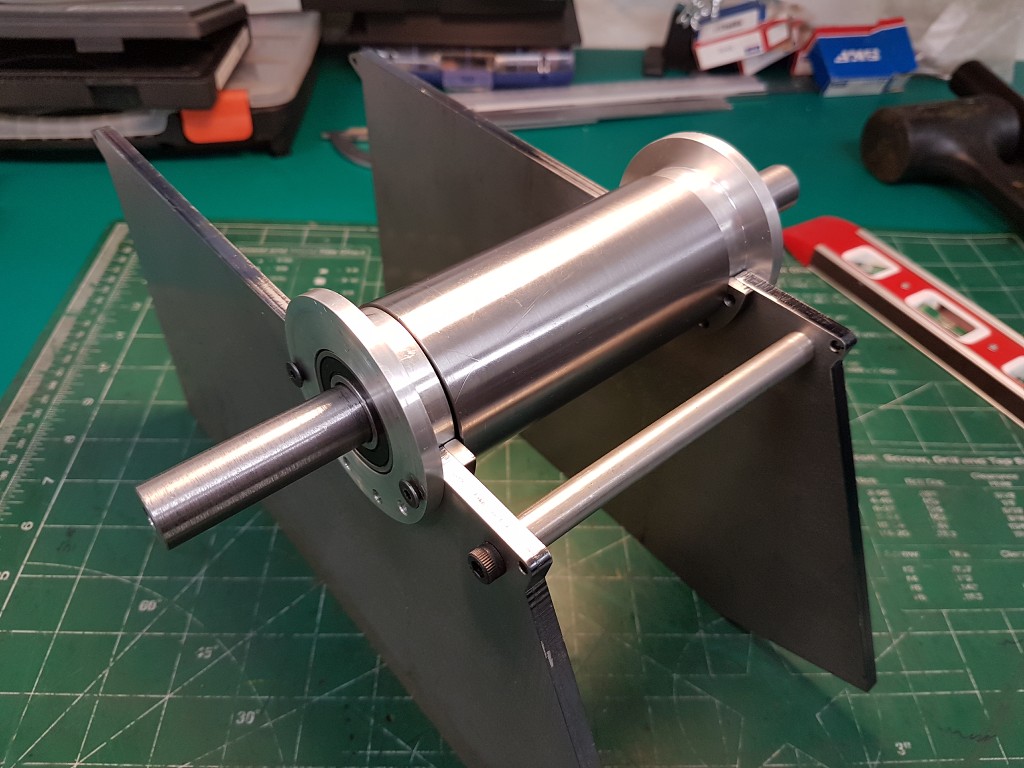

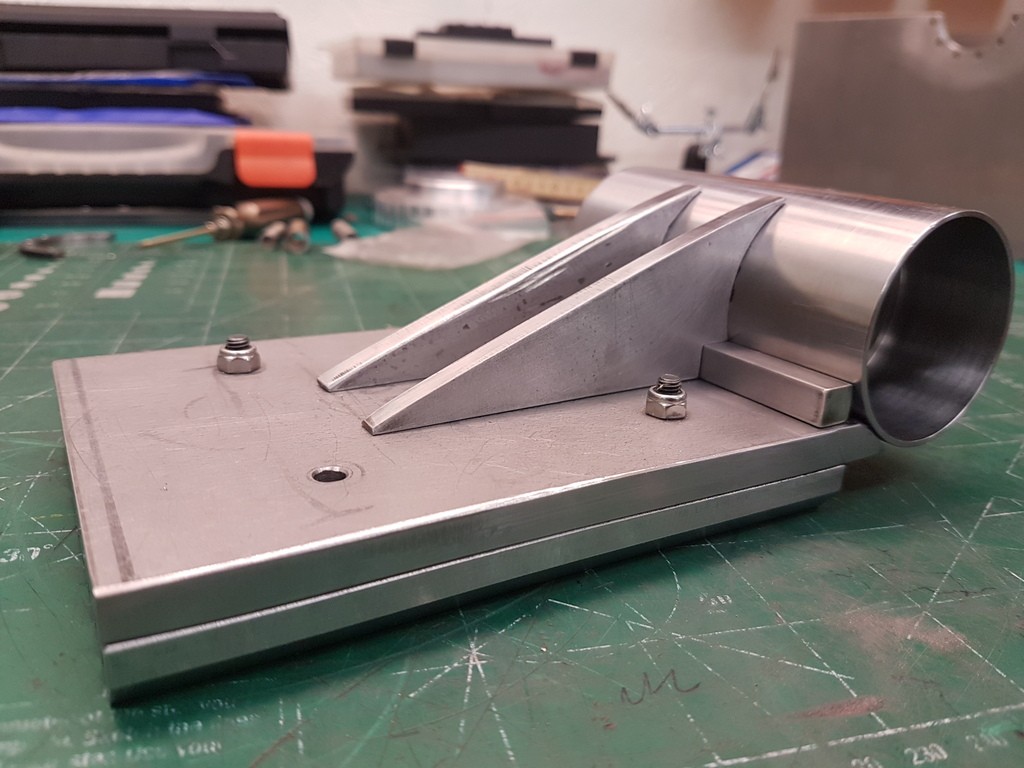

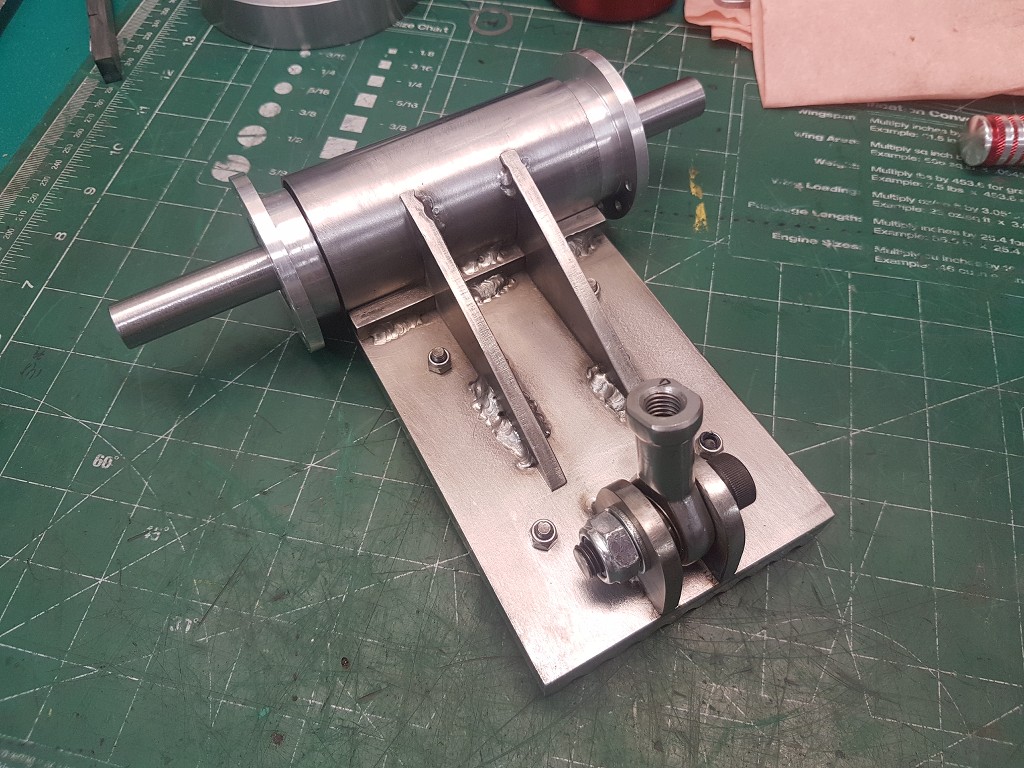

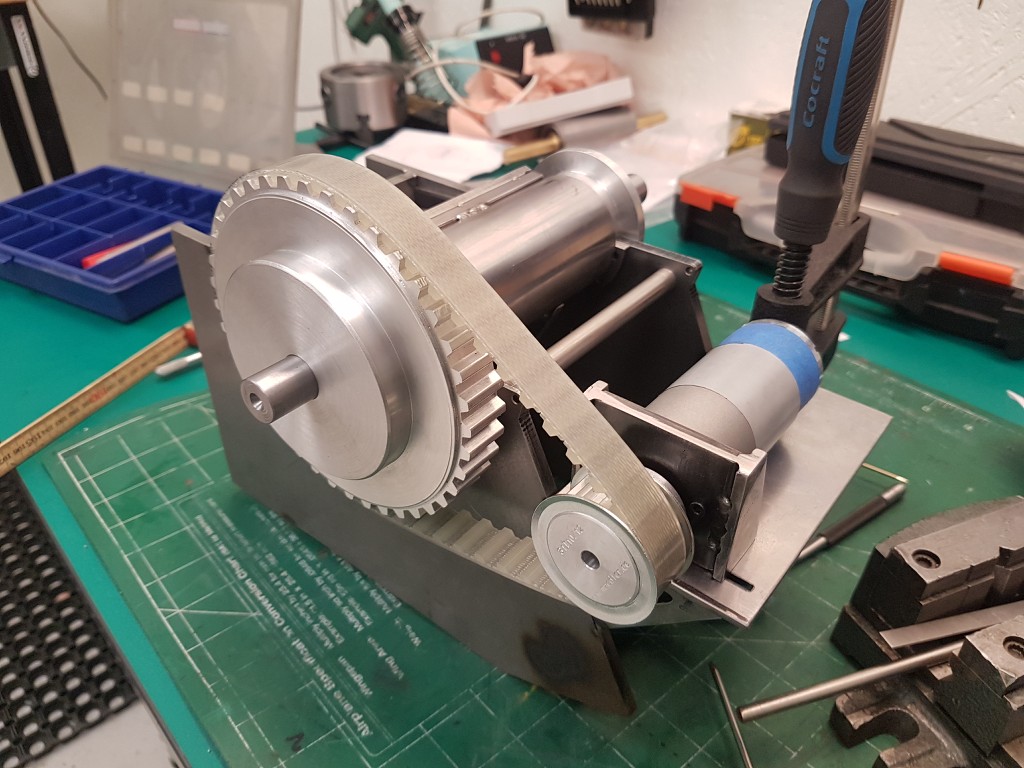

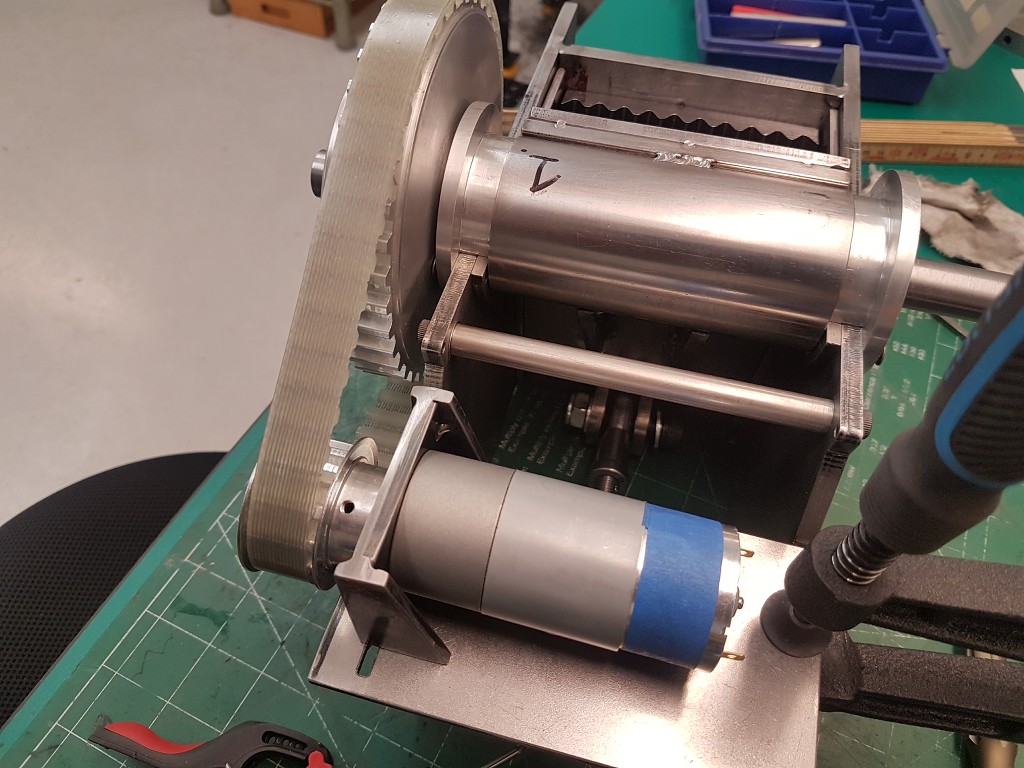

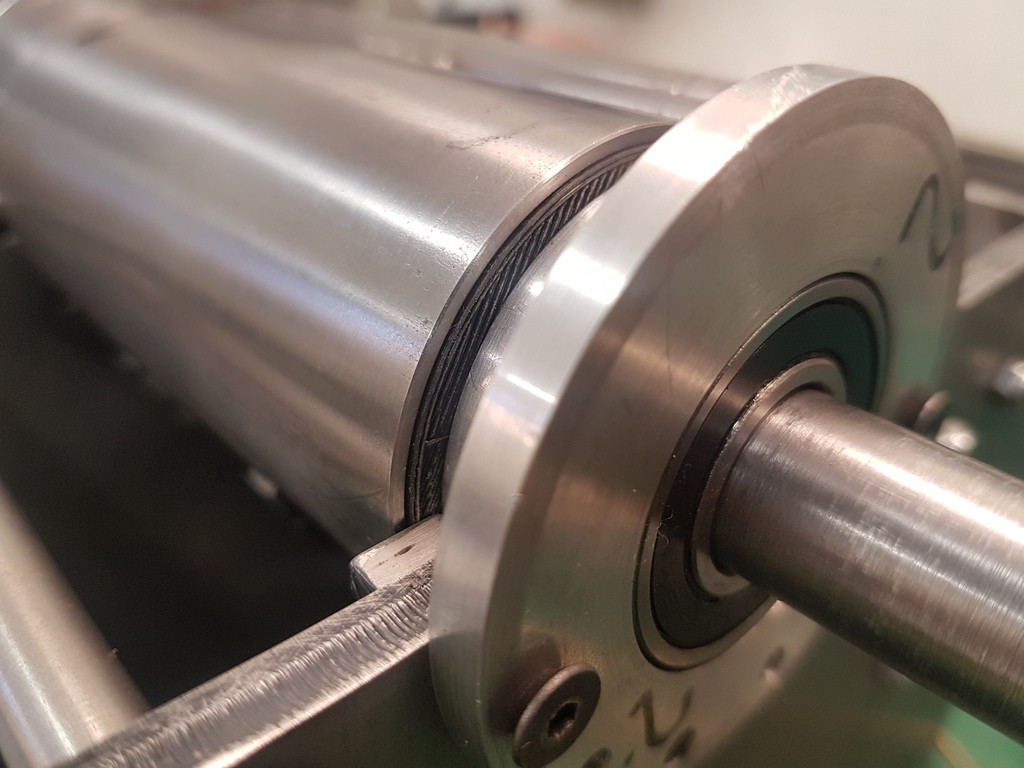

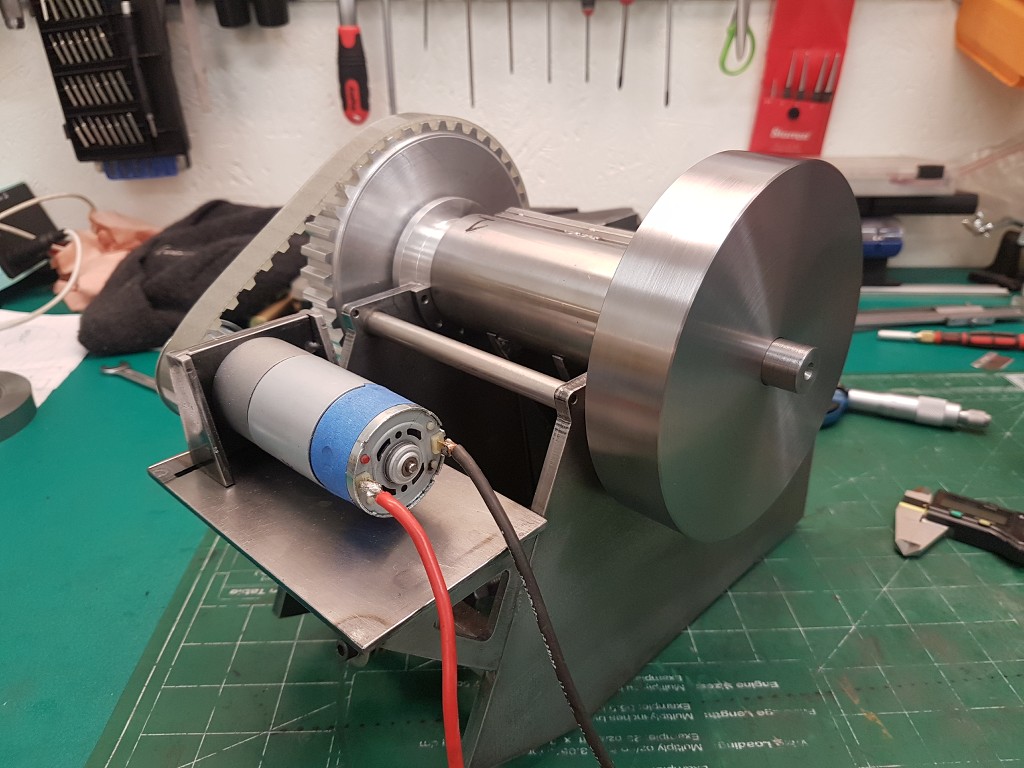

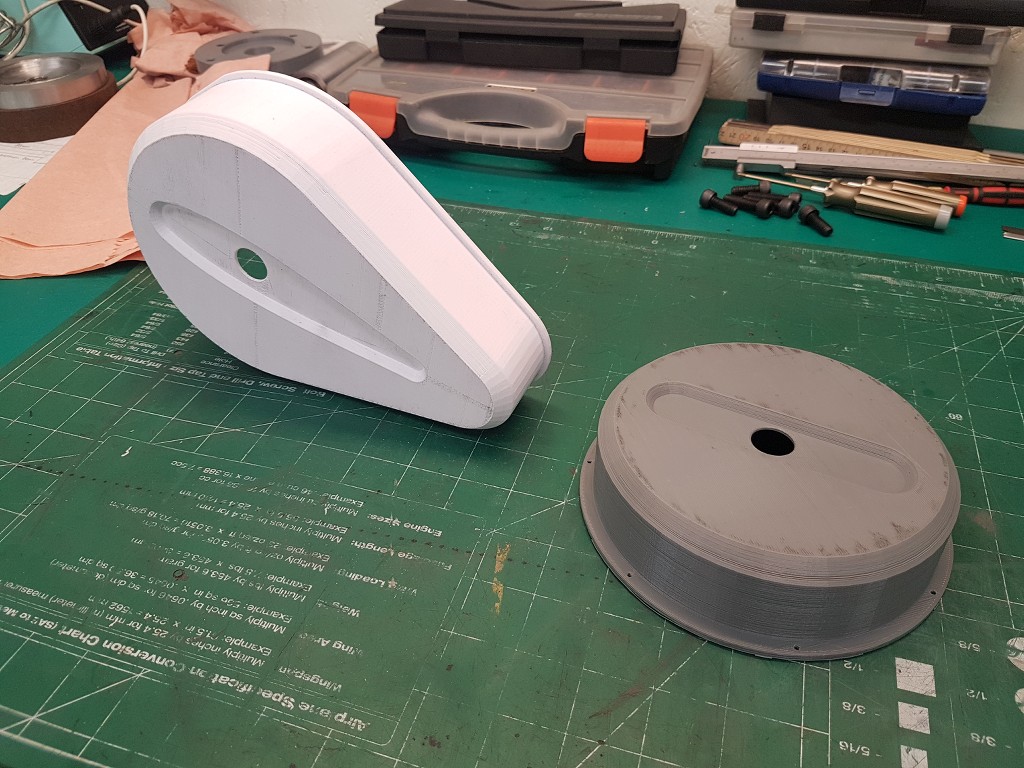

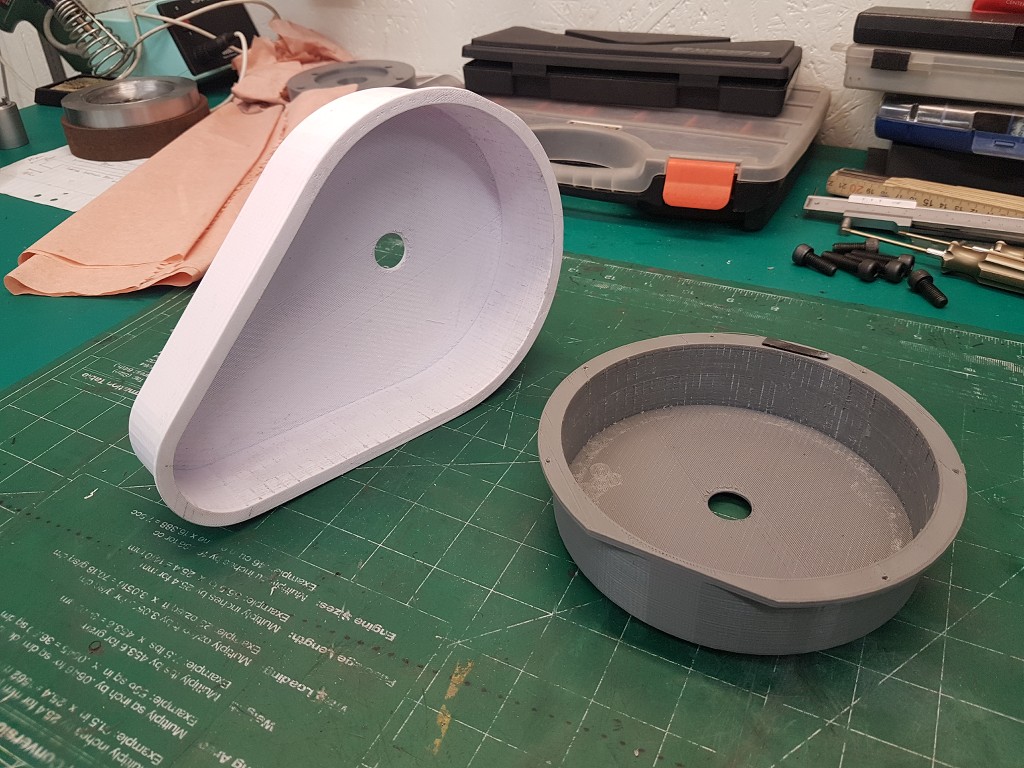

I aslo have bought a house outside town and did a makeover on the garage that was in quite bad shape. So here are some pics of the new crusher im building.             Don´t laugh at my TIG welds, I have just started to learn how to weld with it !       This is how far I have got, I have printed the covers for the beltdrive and flywheel as well, next will be making the flywheel and mounts for the covers.   I also printed a little dust seal for the bearings as they are exposed to the outside.   And lastly, an after and before pic of the new shop!

|

|

#43

|

||||

|

||||

|

Nice work as usual. I see you fixed the jaw teeth like we discussed last time. Hope this works out well.

I like seeing crushing equipment being built. I haven't had enough time to get more done on my stationary crusher. |

|

#44

|

||||

|

||||

|

Good to see you back it Kalle

Congrats on the house purchase & great job on the garage makeover, nice & bright in there now. Did you use LEDs for lighting? Per your tig welds, they look better than mine, I still use my mig more than the tig. As Reg use to say, "gob it on & grind off the excess" ...though I think he does a lot less grinding off nowadays

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#45

|

|||

|

|||

|

Quote:

Yeah, I had them made the right way this time. I hope to finish this one and keep it, I will finish the crusher unit this winter and pick up next autum to continue with the frame, conveyor and feeder. Quote:

Yeah, its a pleasure to work in there now! No its regular armatures I have, I got these armatures for free from a friend. But I did went with another bulb (right word?) in them, these have a more white light then the regular used bulbs and are perfect for me. Yeah you can always grind the welds but I think TIG welds are good enough looking even if they are quite bad, at least compared the bad MIG welds!  I really love my TIG welder, its so clean and you can do small welds, I just need to practice more to get more experience and less shaky hands!

|

|

#46

|

|||

|

|||

|

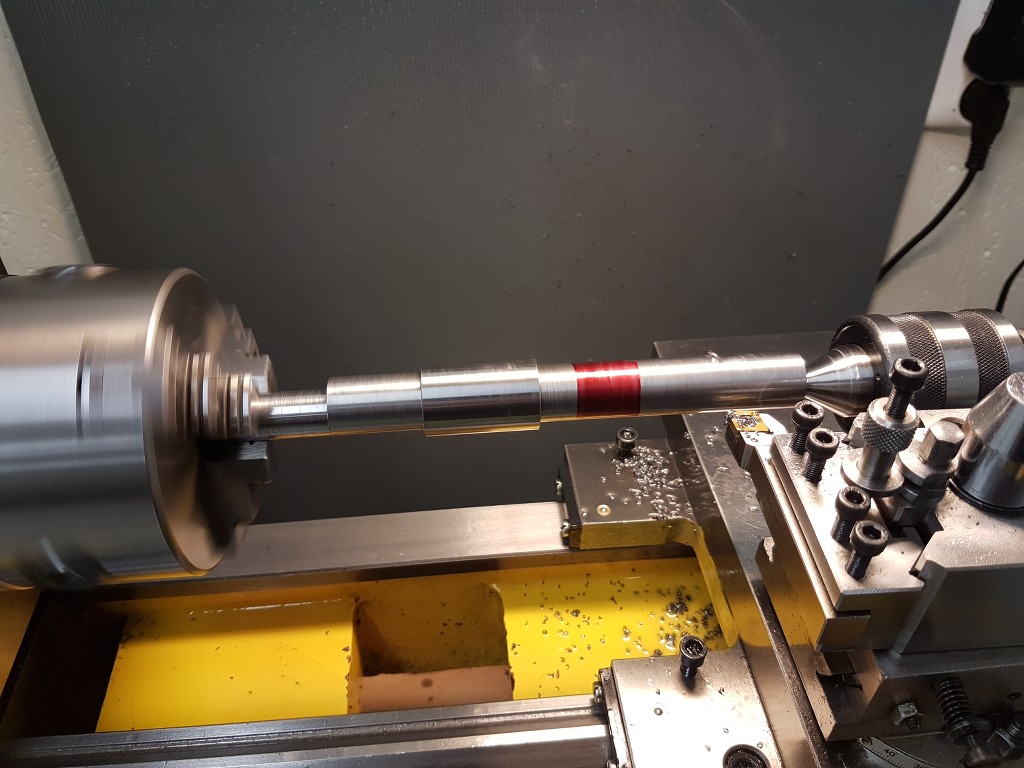

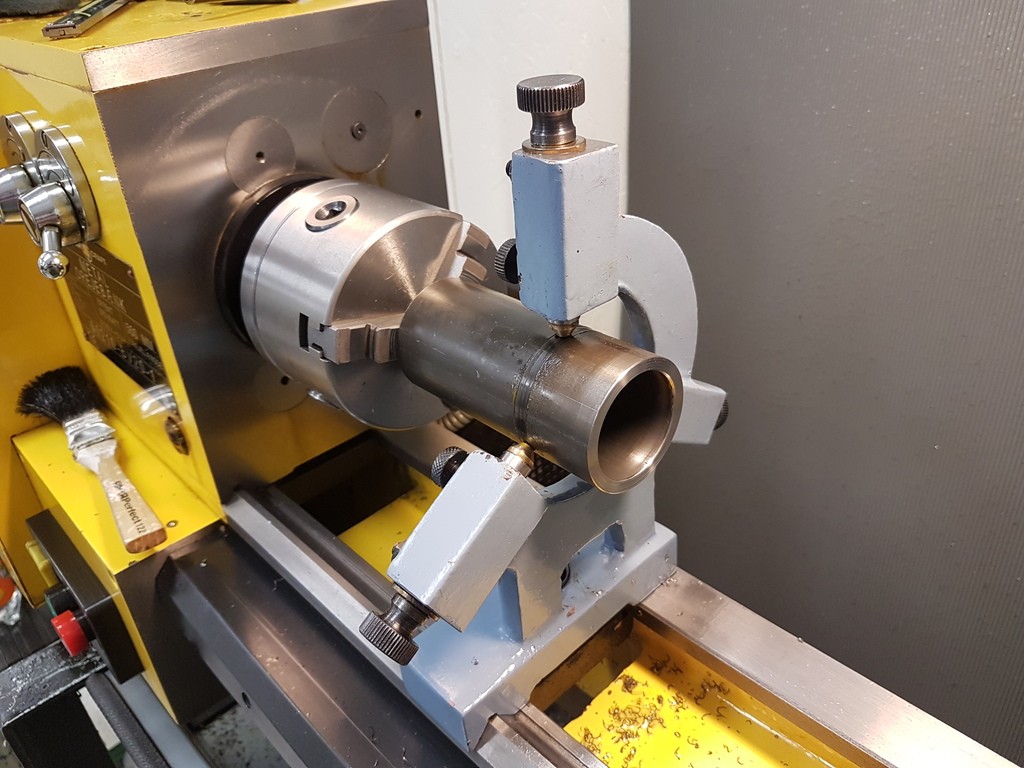

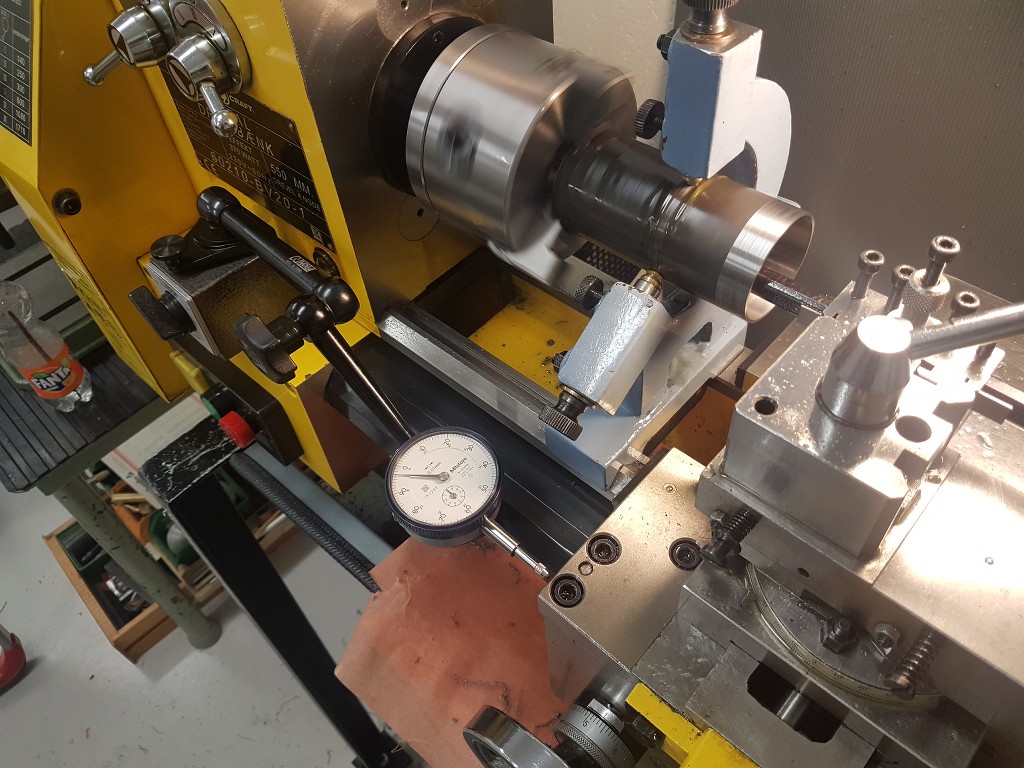

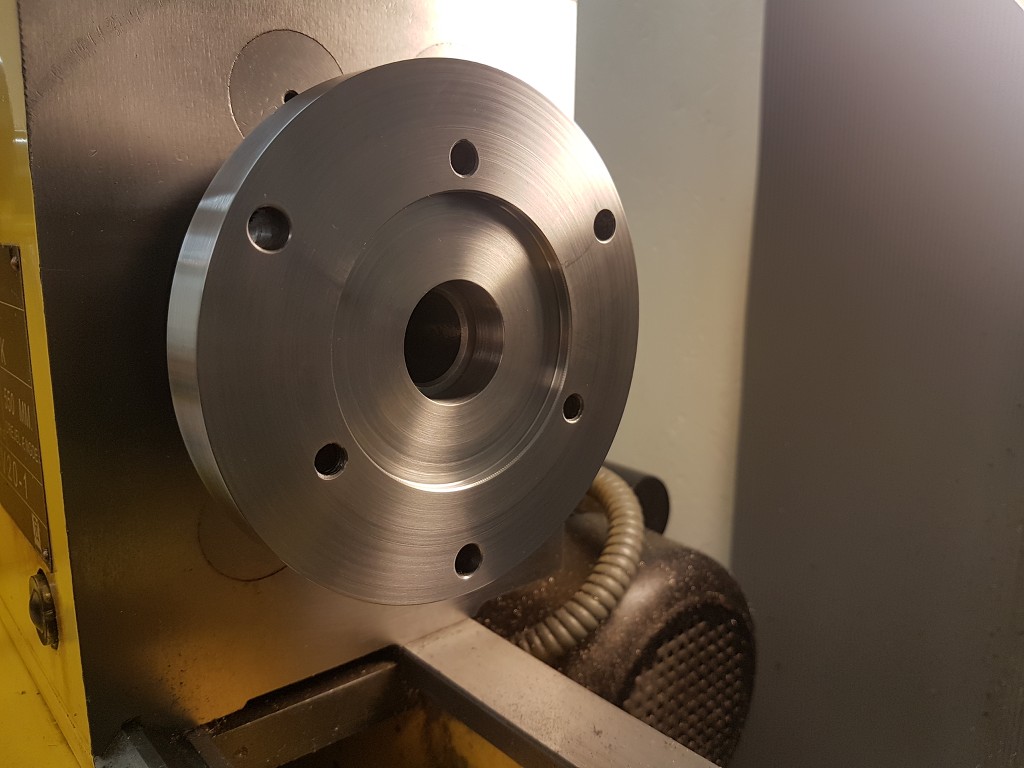

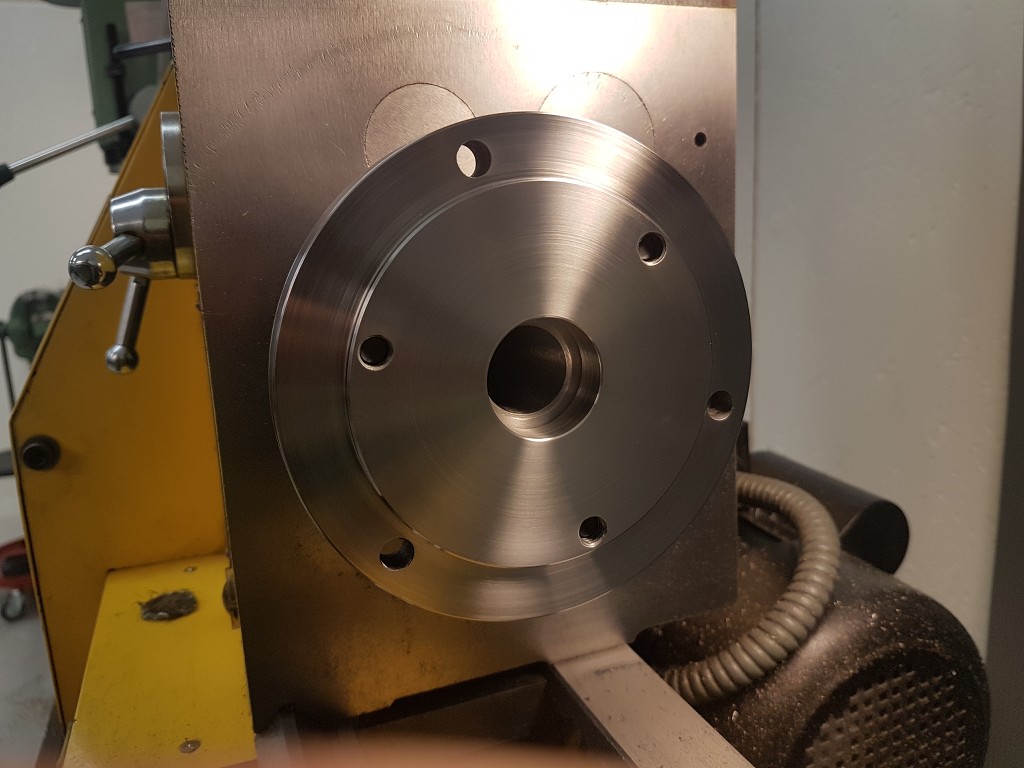

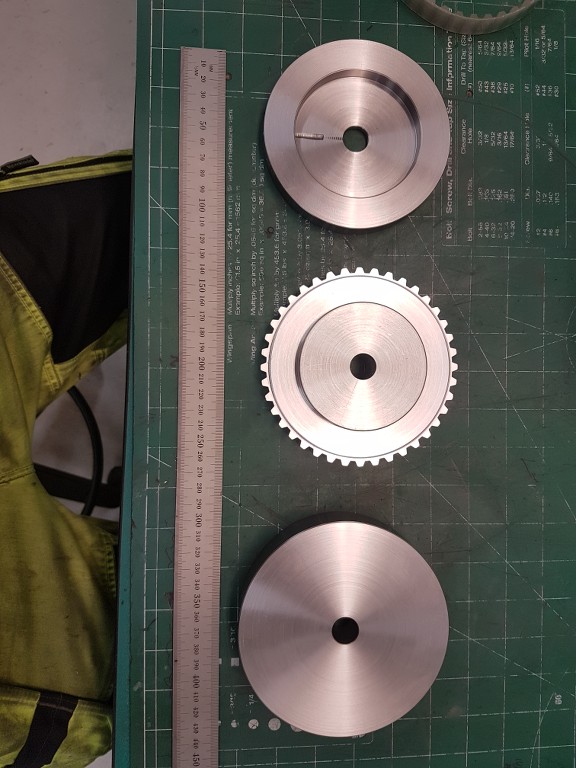

Now it was time to turn the flywheel and the extra weight for the beltwheel.

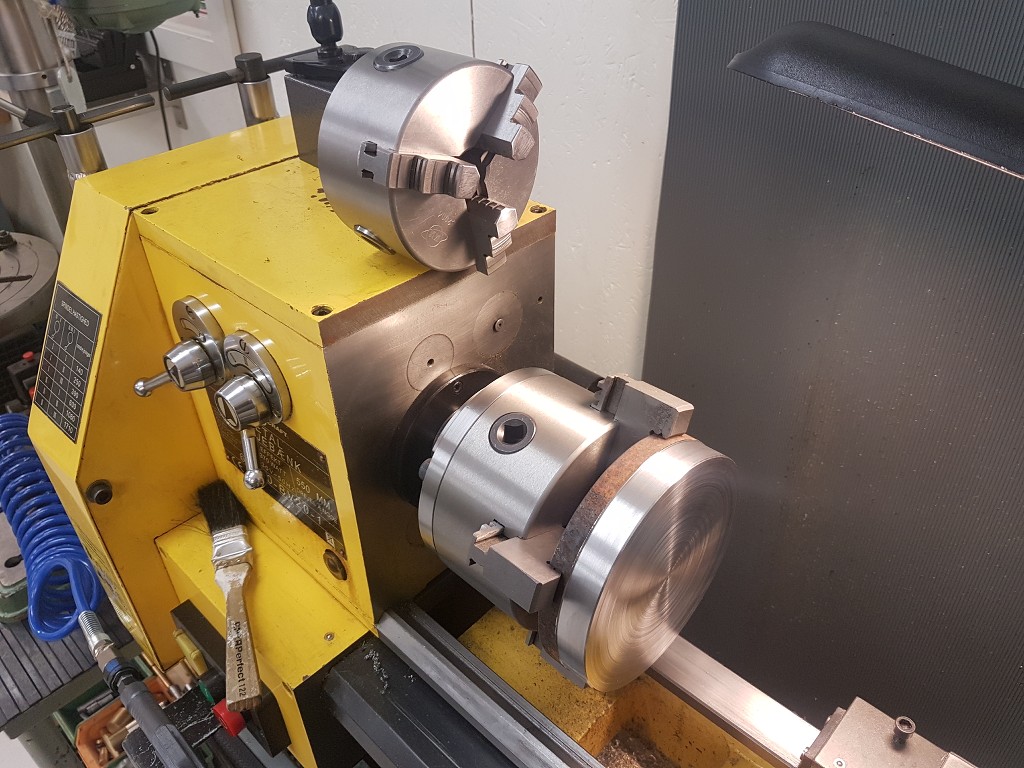

I only had a 100mm chuck on my lathe and it cant hold pieces as large as the flywheel so I had an chuck adapter made by a local machineshop to get the boltcircle right and then I turned the last steps myself. Now I can fit a 125mm chuck and this lathe will last me a few more years!  Here´s some progress on this project. First I turned the internal hole for the flange mount on the spindle.  Then flipped it to turn the outer flange to fit on the new chuck. I had 0.01mm runout on the spindleface with new backplate.  Here mounted and started to turn the flywheel, I had a runout on the chuck on about 0.03-0.04mm, that was measured on a drillbit in the chuck. Good enough for me.   And just a pic of my 10 year old chinese lathe, it has served me good over those years.     Also both covers are printed, also made on a cheap Wanhao 3D printer.

|

|

#47

|

|||

|

|||

|

Fine machined and printed parts you got there. Have you evaluated adjustable bottom opening/distance of the jaws?

__________________

Soyland Industrier |

|

#48

|

|||

|

|||

|

Quote:

I don't really understand how I can do that? Can you explain a bit more please. |

|

#49

|

|||

|

|||

|

I see now you got a joint for a threaded rod as part of fixing the lower end of the moving jaw. Than one got the possibility for a adjustment, say +/- 5mm should do. manual adjustment is fine

__________________

Soyland Industrier |

|

#50

|

|||

|

|||

|

Quote:

Yes I have adjustable jaws in the crusher, I can adjust them probably 10mm in each direction. |

|

#51

|

|||

|

|||

|

|

|

#52

|

||||

|

||||

|

Awesome work!

Calum |

|

#53

|

||||

|

||||

|

It was already looking great, but the printed guards make it look much more scale

__________________

What do ya mean "Cars are neither Trucks or Construction"? It's still scale, and i play fairly well with others, most of the time... |

|

#54

|

|||

|

|||

|

Hello. Really nice work. Im looking to make something similar. Is it pussible to get som rough mesurements ore maybe see your drawings?

|

|

| Currently Active Users Viewing This Thread: 13 (0 members and 13 guests) | |

|

|