|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

|

Thread Tools | Display Modes |

|

|

|

#1

|

|||

|

|||

|

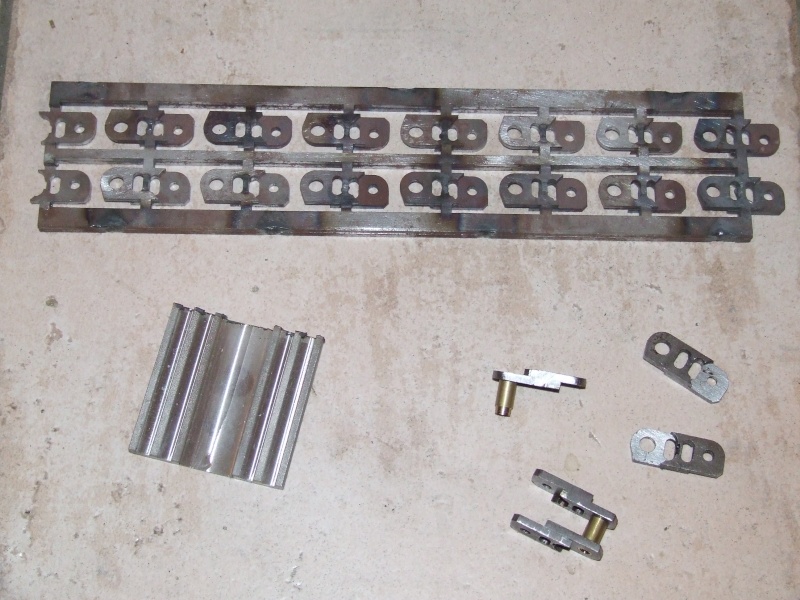

How my tracks are done :

The track links are made from laser cut parts. The frames help to position each half (inner/outter) accurately for welding (TIG). Track pads are milled by pairs.  the track pads are then bent, separated and receive final cuts.   Sorry for this one....not so clear. The links are assembled with a small bushing. This is the reason why the hole of the inner half is larger than the pin hole. Then the links are soldered to the pads.

|

|

#2

|

||||

|

||||

|

Wow! Track work is ingenious and exceptional quality! I have no idea about the cost of laser cutting but the results are amazingly prototypical. Can't wait for more pictures!

Ken |

|

#3

|

|||

|

|||

|

Quote:

Now, if you are a bit lazy and not afraid dealing high $$, you may order these stainless steel track pads, or the cheaper diecast version

|

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|