|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

|

Thread Tools | Display Modes |

|

#1

|

||||

|

||||

|

Recently purchased a Stahl Loader , my first piece of rc equipment, from a great member of the board. It operated great although i didnt like a few things about it and decided to tear into it to learn how it works and fix a few things at the same time. Its turned into a slight redesign since i started. So heres some pics of where im at so far.

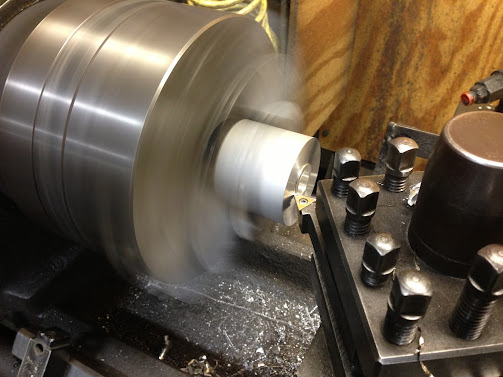

Digging for screws..at this point im pretty sure im not using these parts again..          Blasted some parts  Cutting some new arms from 3/16" plate. Added 1/2" to front length to raise the bucket height a little.  Plasma cutter, my favorite tool. Free hand cuts.   Dusted both sides of the arms to get them flat.   Making the front axle mount. Made it from round stock so i could bore the ID to contour the Diff.

__________________

Jason |

|

#2

|

|||

|

|||

|

Wow, nice job man!

I bet this will turn out to be a great thread, keep it up!

|

|

#3

|

||||

|

||||

|

Very nice Jason! I'll be watching this one for sure! Glad you picked this machine up, when it was listed for sale. I'm really looking forward to seeing you rebuild it. The Stahl WA500s are nice machines. To be really perfect and scale models, I think they just need a little massaging. Just a few extras here and there. What else do you have planned for it, in terms of detail parts? You've got a heck of a machine shop at your disposal. Surface grinder and all!

__________________

Nathan |

|

#4

|

||||

|

||||

|

Thank you!

Id actually be open to suggestions for details to add...I guess i do have a few things id like to do...Maybe fenders for the rear. I may rebuild the steps and platforms, these are falling apart. Replacing the blue glass with clear lexan and make a new counter weight from a solid steel block...Oh want to make a new radiator grill, maybe something from black screen..? Want a quick release too! But havent found any info yet on how to make one of those. Make a hub cap with a new wheel face which is more scale looking...but i dont think our indexing chuck for the mill is any good..havent looked at it in years. We have 10 cnc turret lathes that could do that but they are all running high production jobs and rarely have any open time. I may have to draw something up and just tell the set up guy next time to" make this".. Oh and gonna print out a driver..too bad i dont have a scanner, Id scan myself and make ME the driver.

__________________

Jason |

|

#5

|

||||

|

||||

|

Very cool, Jason. While you're at it, you should basically re-make the entire main chassis out of steel. More weight, more traction.

As for the details, just look at the real WA500 loaders and add what you see. Mirrors, light buckets coming off the frame area where the loader arm pivot bushings are, and nicer hand rails. That rear grille could use some detail too. Don't forget the windshield wiper! Any place to can get rid of the scew heads, definitely consider it. Nothing ruins a scale model like phillips head screws sticking out of a sheet metal body, where there shouldn't be any visible. Weld things together instead. It almost looks like you already made the front half of the chassis out of steel and welded it? As for the details, just look at the real WA500 loaders and add what you see. Mirrors, light buckets coming off the frame area where the loader arm pivot bushings are, and nicer hand rails. That rear grille could use some detail too. Don't forget the windshield wiper! Any place to can get rid of the scew heads, definitely consider it. Nothing ruins a scale model like phillips head screws sticking out of a sheet metal body, where there shouldn't be any visible. Weld things together instead. It almost looks like you already made the front half of the chassis out of steel and welded it?

__________________

Nathan Last edited by Espeefan; 04-14-2013 at 07:18 PM. |

|

#6

|

||||

|

||||

|

Gosh!! the tools & the knowledge you have at your disposal, I'm envious.

I see you traced some extra arms, were they meant for me too?!  The added 1/2" length will changed the geometry of the bucket rotation... you'll cross that bridge when you get to it? The added 1/2" length will changed the geometry of the bucket rotation... you'll cross that bridge when you get to it?I'm looking forward to seeing what you come up with for functional improvements.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#7

|

||||

|

||||

|

Nate, Exactly my thoughts too on the phillips heads lol. And thats what i did. Welded the front end from inside. The light buckets and mirrors are a good idea..Didnt even think about that and wiper too

But did consider remaking the rest of the chassis out of steel as well..Why not? should be alot easier than the front half. And already its putting on some weight. Heres a few more pics. Scale bolts for the front hatch plate= Cool! Need more of that going on. And Stainless cross supports for the pivot points.. Thanks for commenting! But did consider remaking the rest of the chassis out of steel as well..Why not? should be alot easier than the front half. And already its putting on some weight. Heres a few more pics. Scale bolts for the front hatch plate= Cool! Need more of that going on. And Stainless cross supports for the pivot points.. Thanks for commenting! Joe, Thanks. haha, those extras were my practice pcs. Needed to get my stance and hands working together.. Machine shops have been the family business since my grandfather started it when he was my age. All the manual machines I use are just for our little fab area. Our main business is CNC Grinding. I thought about that. It shouldnt be a big deal to adjust the geometry. I think its all in the length of the connecting rod for the bucket tilt. Yes ill deal with that in a short while hopefully.

__________________

Jason Last edited by JDH429; 04-14-2013 at 08:42 PM. |

|

#8

|

||||

|

||||

|

Awesome job! I'm just not sure why you spent the money on that loader when you clearly could have (and basically are) scratch building one

? Anyway, I love the work you're doing! Keep it up and keep us posted! ? Anyway, I love the work you're doing! Keep it up and keep us posted!Reg |

|

#9

|

||||

|

||||

|

Man, that's awesome Jason! You'll pretty much have a brand new loader when you are done. It looks like you could have bought the gear motors, the hydraulics, and wheels, then built everything else yourself. You definitely have the talent!

__________________

Nathan |

|

#10

|

||||

|

||||

|

Reg, Nate- Thanks guys, Yes i agree and your right.. but this being my first machine. I wouldnt know where to start. I never even seen one up close till i got this one. im good at copying something...Not good at making up designs without seeing it first..BUT i think im sure i can scratch build my next model and i have been thinking about what size Dozer i want to build. Only hard part about that would be the tracks..Again if i had a track peice to examine i could copy it. I have made plastic track parts with my Printer. I might have to visit the CNC machinist down the street for that. The rest is very doable after attempting this. I look at the cost i spent on this to have been also part of the learning process... Anyone want to buy a used wa500 chassis? lol Thanks for the nice comments.

__________________

Jason Last edited by JDH429; 04-14-2013 at 08:59 PM. |

|

#11

|

||||

|

||||

|

Yeah, I saw the business name at the bottom of your email weeks ago & looked it up.

Quite an occupation you have going on there... you a jack of trades in that shop? owner/operator too? Quite an occupation you have going on there... you a jack of trades in that shop? owner/operator too?You sure did a mighty fine job of cutting & shaping that metal.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#12

|

||||

|

||||

|

Quote:

__________________

Nathan |

|

#13

|

||||

|

||||

|

Quote:

Nate, I know right? Stamped aluminum sheet screwed together.... Can you imagine my surprise when first getting a look at this loader? Lol. I immediately thought what you just said. ! But I'd have to say this is a rather complex model..? Maybe not as intricate as an excavator but its got some engineering into it. Just needs more meat on it. So that's what I'm doing. I originally didn't set out to scratch build a loader.. But after seeing this one I knew I could improve it and the Bondo wasn't sitting well with me, there's no way to take this apart easily to fix something if I had left it. And maybe ill add some value to it by doing this. It's fun tho..the building part. I think I enjoy that more than actually driving it... Well that's to be determined yet.. I think I finally found an interest in something( rc construction) that will keep me interested. Glad I found this board too. Wish I could have learned the basics from the original garden trucking board. This board seems to be the next level where maybe a lot of basics have been left on the old board. But still the best place to currently be.

__________________

Jason |

|

#14

|

||||

|

||||

|

Nice work! This will be really cool.

__________________

RIP FGD 12-19-11 To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#15

|

|||

|

|||

|

So, JDH,

After you've basically replicated it to your own machined specs, what you going to do with the original? Re-assemble it and sell it? Or re-assemble it and shelf-queen it? Just curious. I doubt I'll ever be able to afford one of these hydraulics, besty I could afford would be one of the styrene/electric ones, for show, not work. Will enjoy the rebuild, and wishing I had access to such a shop. I like DIY. WhiteWolf |

|

#16

|

||||

|

||||

|

Quote:

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#17

|

||||

|

||||

|

Quote:

The thicker components of the WA500 probably are CNC machined, but I would also wager that the thinner components are stamped. I'm not saying it's a bad thing. Stamping yields high quality parts, held to tight and accurate tolerances too. Don't think of it as a knock on the quality of the model. The axle mounting brackets for the front axle, the cylinder mounts for the bucket cylinder, the front fenders, the c-channel bracket that the steering cylinders bolt to, the hood, the rock bucket components, and many of the cab parts could have been stamped. Progressive dies can cut, punch holes, and form small parts like these, and do so accurately. I'd almost guarantee you that many of those smaller parts could not be formed with a brake press. The bends would be to close together for the tooling. For a stamping die, it would be a cake walk. You should see what a progressive stamping die can make. You'd be surprised. The thicker components of the WA500 probably are CNC machined, but I would also wager that the thinner components are stamped. I'm not saying it's a bad thing. Stamping yields high quality parts, held to tight and accurate tolerances too. Don't think of it as a knock on the quality of the model. The axle mounting brackets for the front axle, the cylinder mounts for the bucket cylinder, the front fenders, the c-channel bracket that the steering cylinders bolt to, the hood, the rock bucket components, and many of the cab parts could have been stamped. Progressive dies can cut, punch holes, and form small parts like these, and do so accurately. I'd almost guarantee you that many of those smaller parts could not be formed with a brake press. The bends would be to close together for the tooling. For a stamping die, it would be a cake walk. You should see what a progressive stamping die can make. You'd be surprised.

__________________

Nathan |

|

#18

|

|||

|

|||

|

those cab panels.... nice alignment! was it user error from somewhere in its life or is that how these fit together?

thats some precise plasma cutting. i love seeing all that talent people have come to light. forces me to keep practicing ';0

__________________

Premacon 956 ordered. ETA late 2016. To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. The waiting games are real. |

|

#19

|

||||

|

||||

|

Very nice thread. You got some good skills my friend. I can't wait to see the finished machine.

__________________

To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. If you got it, a Trucker brought it.... |

|

#20

|

||||

|

||||

|

Nice work Jason !

So first you show us your talents with a 3D printer and how well you work with plastic and meanwhile.... Your a master of metal too!    To say this loader found a good home is wrong  This loader has found the RIGHT home for sure!  Mario |

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|