|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

|

Thread Tools | Display Modes |

|

#141

|

||||

|

||||

|

Lol awesome use of princess auto! Great build!

__________________

Rc's are like pringles. You can't have just one!! my YouTube is - To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. Subscribe!! My Facebook - To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#142

|

||||

|

||||

|

KP, glad to hear you found the problem. As Mario said, getting stumped by the unusual is normal in heavy equipment repair though I really enjoy working through a problem and (hopefully) figuring it out. I recommend using a ball-type external PRV on a low pressure system like you have.

Ken

__________________

Big iron is awesome! |

|

#143

|

||||

|

||||

|

Took the stock PRV apart only to find it was not seating properly....go figure...so I recut the seat angle and what do ya know....it works better now, who would have thought it was bad right from new??!!

With one control being used it operates at 240 PSI , the PRV will open around 325 PSI and hold steady at about 275 PSI. When both controls are used the pressure drops to about 150 PSI which is a bit strange, may just be how things work with an open center valve. The flow and cycle time on the cylinders is almost right on the money now.....still could be faster I think....next will be to increase the pump RPM and get a bit more flow, but first I need to make a bit bigger drive pulley on the motor. Thankfully this is finally starting to work like it should.... With the controls in neutral (no load) the pump turns at 1700 RPM and drops to about 1400 RPM with a load. The motor draws 20 amps under load and 12 amps when the controls are in neutral....yikes...really going to need the two 14AH batteries!! LOL Here is a short test video......still think it is too slow!! But much better than what it was before  [IMG] |

|

#144

|

|||

|

|||

|

I think the speed is about right. I'm enjoying this build.

|

|

#145

|

||||

|

||||

|

Looking good KP. When I built my Volvo I bought a Mustang convertible top pump with cylinders for $80. I thought I had found the ultimate poor mans hydro pump!lol Anyway, it fit in the machine perfect but I did a quick test and it drew 13amps just firing up with no load. In my machine there is only enough space for one 12ah battery so I had to ditch it and change to a smaller pump and motor. At least you have the space for more batteries! If you can increase your pump rpm to run all cylinders at once at a happy speed you will be able to dial in the TX mixing on the pump and valves so that it speeds up or down depending on the movements. This should help with run time and make the machine easier to run.

|

|

#146

|

||||

|

||||

|

i cant wait to see this shovel dig!!! looking good

|

|

#147

|

||||

|

||||

|

Looking good! I think the speed is pretty darn close. Although everything is new and tight and maybe a little more speed would be nice in the long run, you have to keep in mind this is a big machine and more about sheer power than being nimble and quick. Also looks more realistic when moving slower and smooth compared to those machines you see with super fast and jerky motions.

Definitely moving forward on the hydraulics part. With the proper gear reduction on the pump drive hopefully you can kill 2 birds with one stone and get that flow you want and increase run time.

|

|

#148

|

||||

|

||||

|

I would say your speed is pretty good there, how fast it needs to be will depend on your ability to control the model while operating 4-5 functions simultaneously.

My 850 only reaches max pressure when cyl(s) reach end of stroke or the force needed is beyond the cyl's capacity. At an idle the press is less than 1/3 & arm moving through the air is 1/2 - 2/3.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#149

|

|||

|

|||

|

I think the speed is about right. The PC1800's we have at work are slow compared to the PC2000's and PC1200's. Generally the bigger the machine the more power and less speed.

I would personally rather have the machine a little bit slower but fully controllable than fast, twitchy and hard to control. |

|

#150

|

|||

|

|||

|

I have been following your thread with interest . I am using roughly the same size gear as you . I think from memory you are using a 2.2cc pump and an open centre spool valve. I am using a 1.6cc pump as i only have 4 cyls on 1/10 scale .

I was interested to see how you went with the open center valve as i was going to use the same , but i read they are not good for uses other than hydraulic motors- mainly due to sealing around center . I liked the fact the pressure is not present unless using a control , but can not get my head around how you get pressure on one vale while the other 2 are -open to tank? - I noticed you get some creep on the other cyls ,but maybe that is because you have removed the detents and it is hard to find the exact center ? Strangely after watching your video i think i may go with closed centre spools and use the throttle mixing in the radio to increase pump rpm when a channel is used ( ie -- theoretical numbers --%50 rpm for main boom=2x cyls , %20 for the arm and %20 for the bucket ) . Which would also turn the pump off when no hydraulics are used . Maybe this is common , but i can not find videos where they do this -maybe there is a reason and i will find out through trial and error or maybe some on on here could explain is this is a bad idea and save me time ? I am looking forward to seeing you progress with this model as you already look like it will be very well made ,, all the best .

|

|

#151

|

||||

|

||||

|

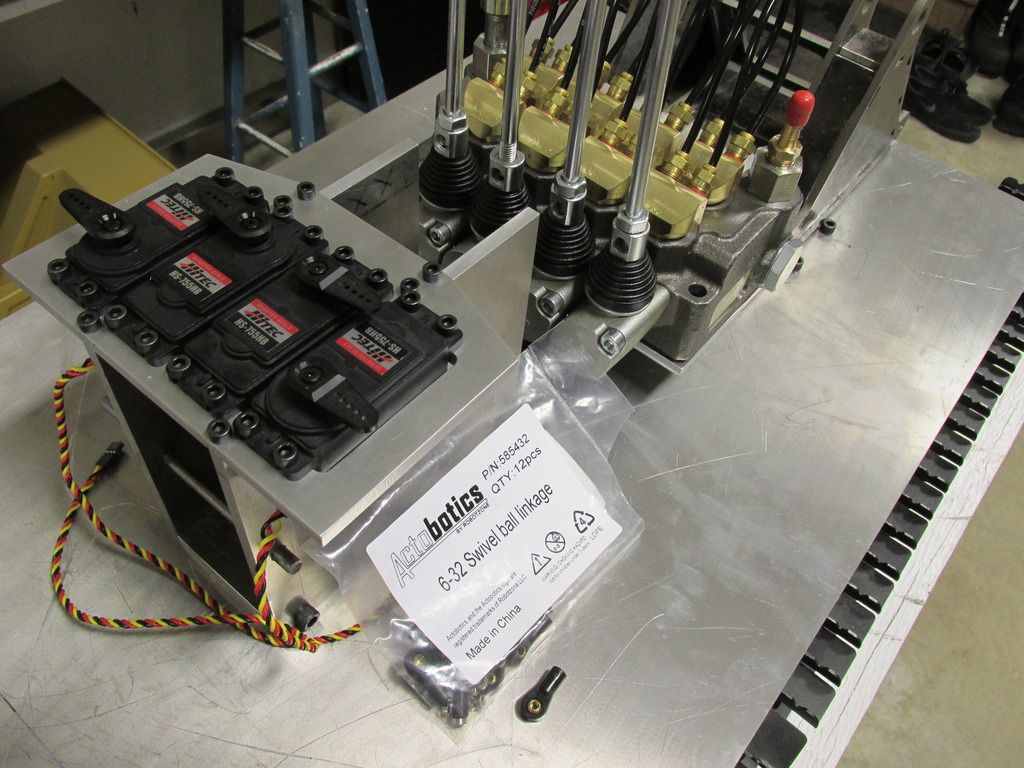

Yes the pump I'm using is about 2.2cc/rev. The open center valve body can be hard to figure out how the open center works without actually being able to mess around with one....but it does work!! LOL

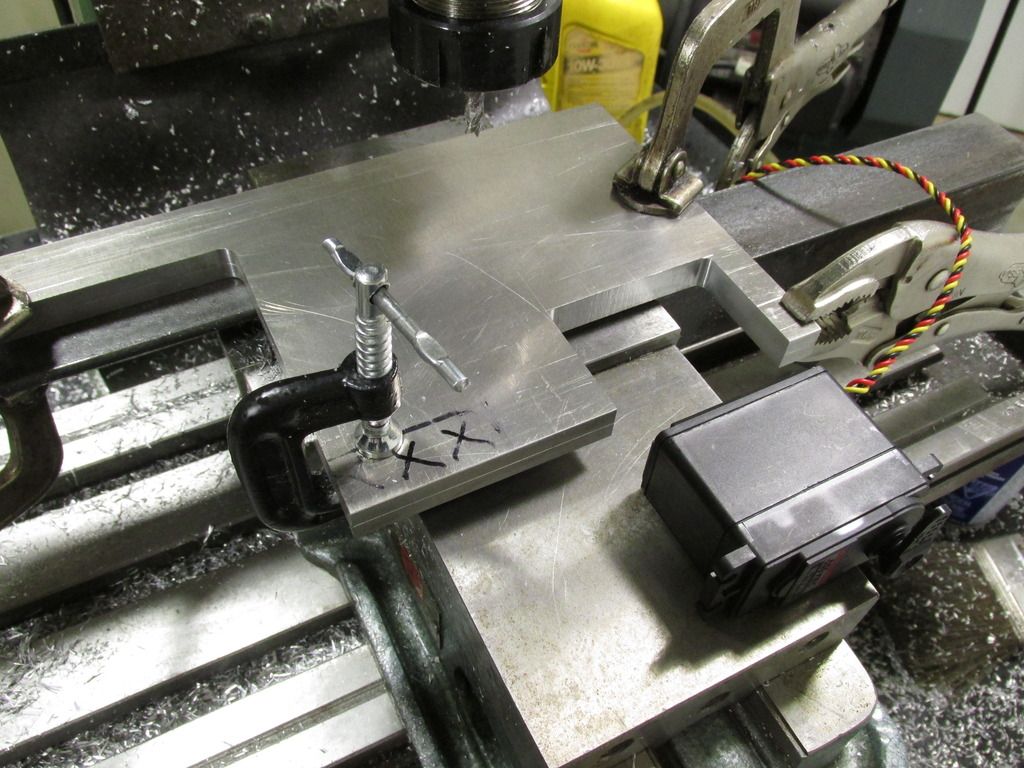

I changed this valve body to a closed center by simply installing a "closed center plug" which is on the right hand side in the photo. So if you use an open center valve be sure it can be changed to a closed center when the proper "plug" is installed, this will give you the option to go either way, closed or open. The valve body and the matching center plug is from princess auto. Yes you did see the cylinders creep...lol.... and yes it is because I didn't get the controls centered , the control return springs are removed Using the valve with a closed center didn't really improve anything, only slightly more responsive due to the constant high pressure, but the pump motor is always under load draining the batterys even when the controls are in neutral, I'm hoping to try and avoid using an ESC on the pump motor so I will most likely run this with the open center...time will tell. [IMG]

|

|

#152

|

||||

|

||||

|

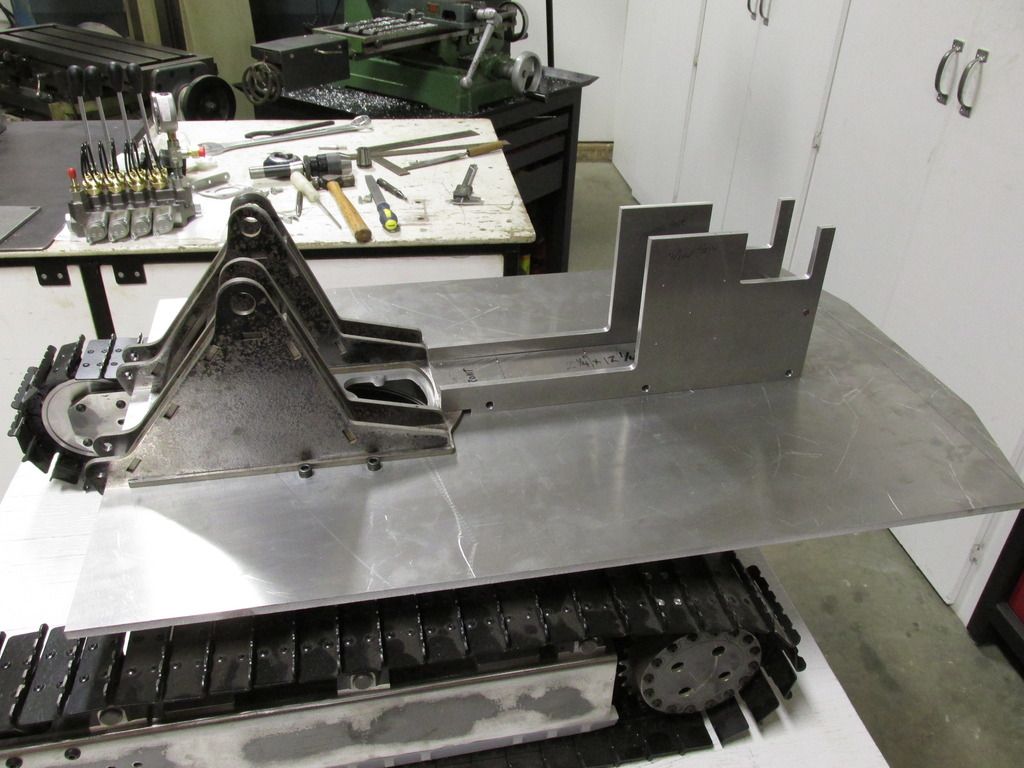

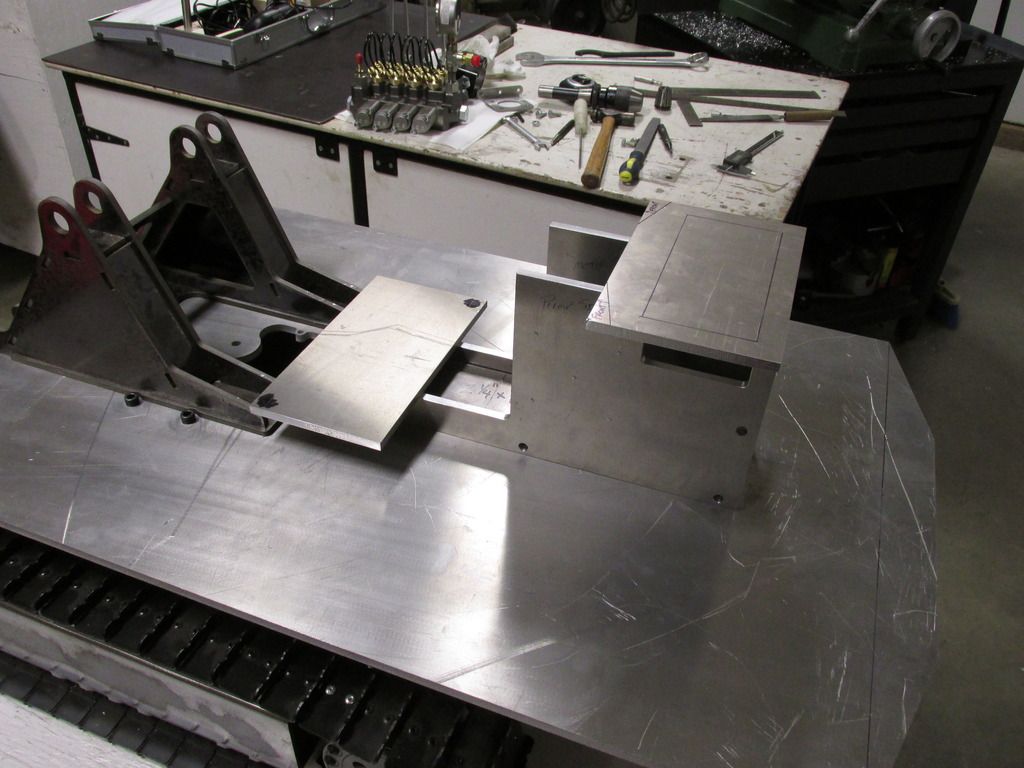

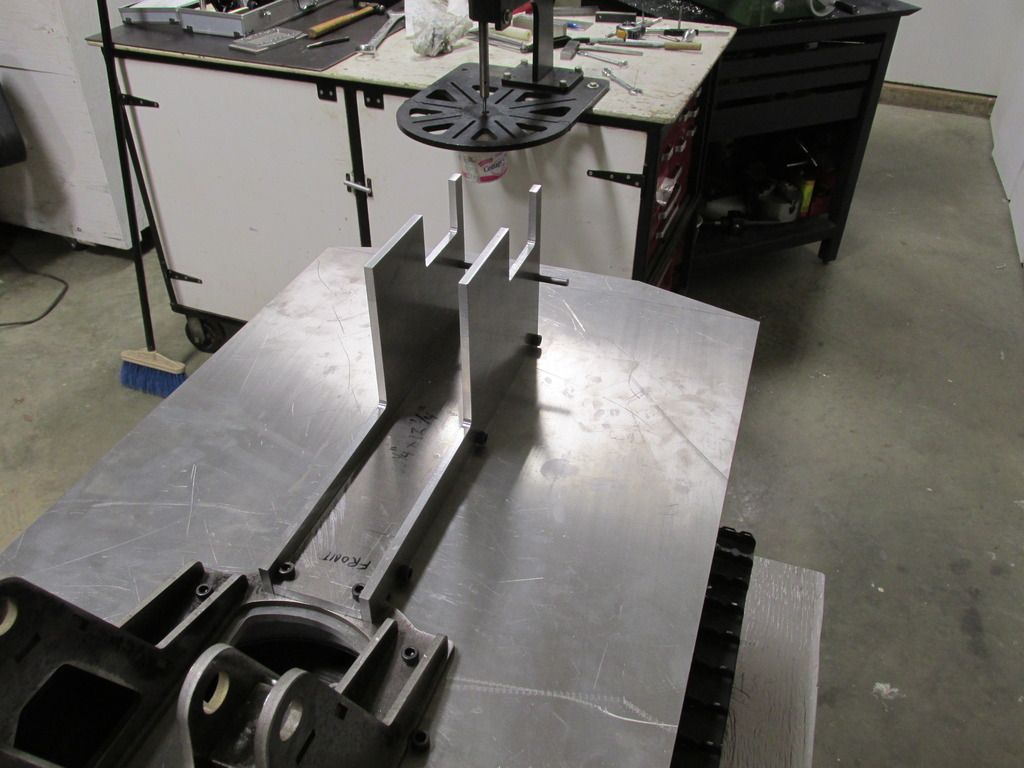

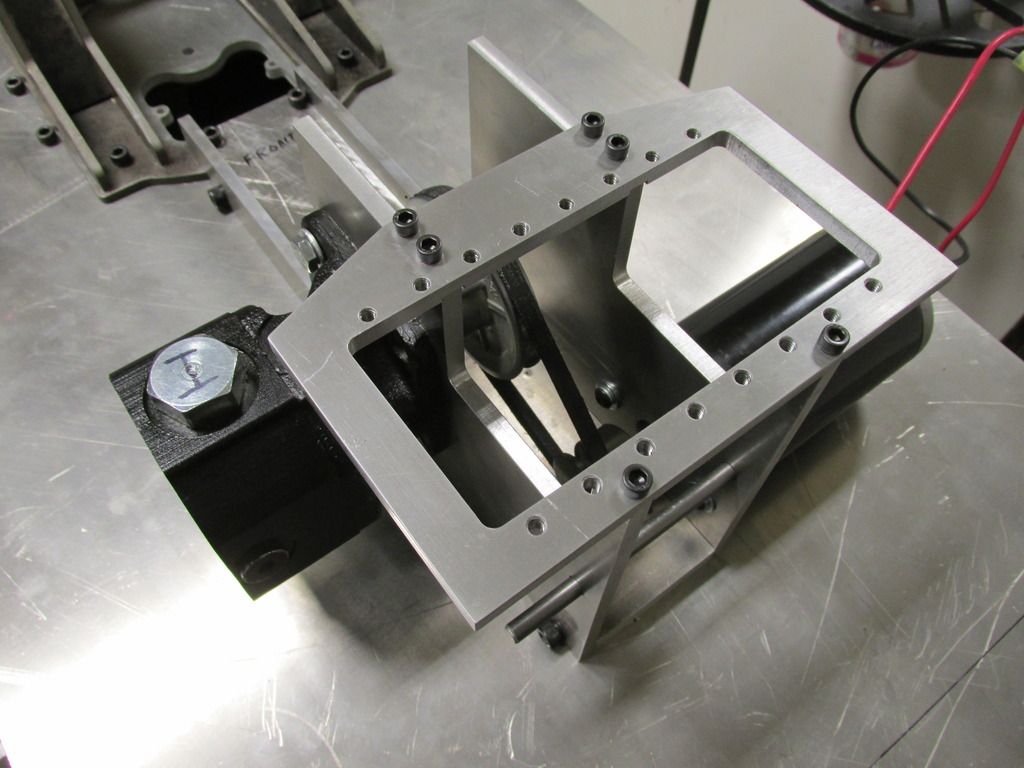

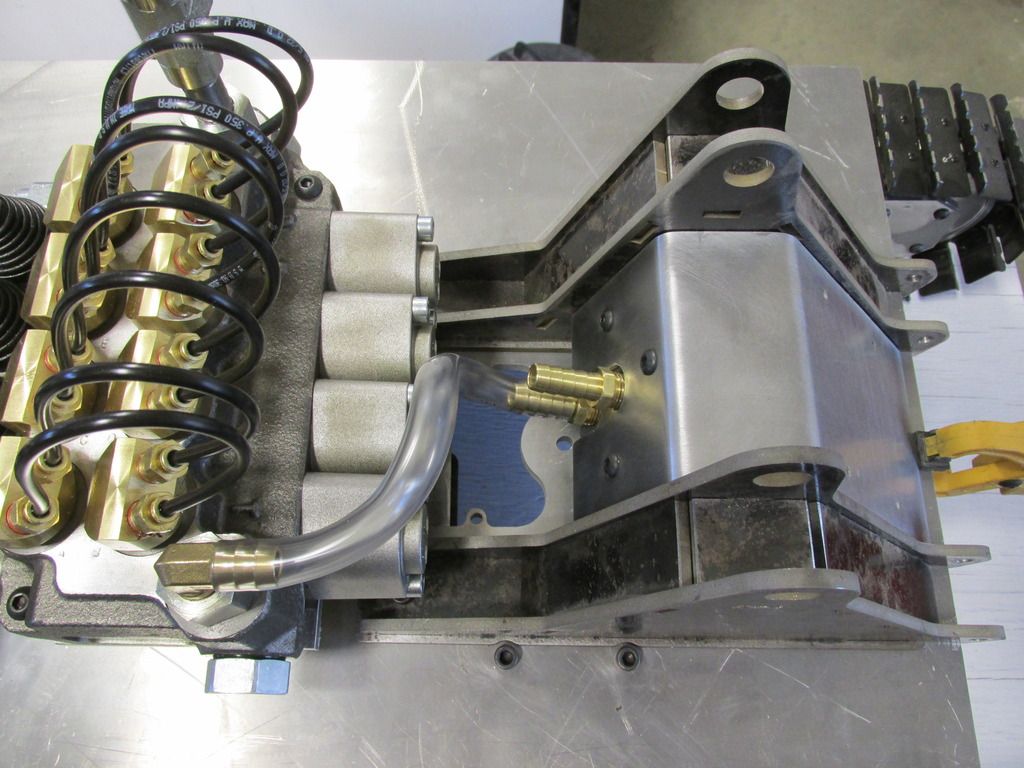

Started building the frame that hold the hydraulics etc. It will also help support the 1/4" ALM. floor, and once the body panels are installed it should be nice and solid....

[IMG]  [IMG]  [IMG]  [IMG]  [IMG]  This will be the general arrangement of everything....valve body, pump, motor and servo tray all in one frame or a least thats the plan for now...LOL [IMG]  [IMG]  [IMG]

|

|

#153

|

||||

|

||||

|

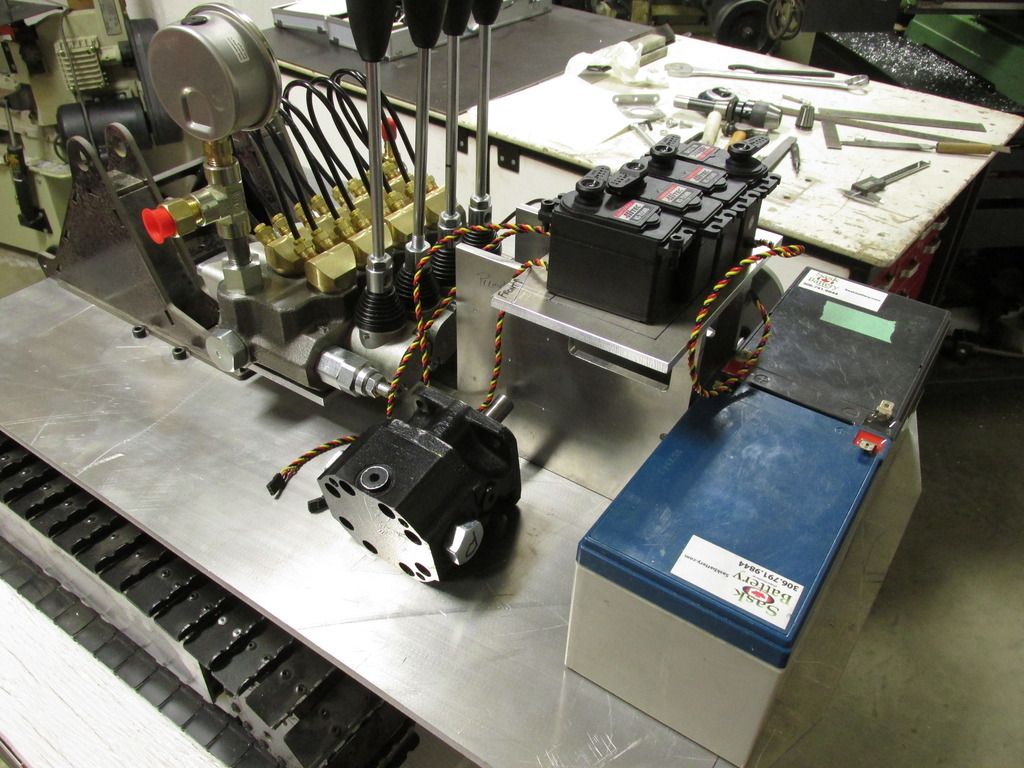

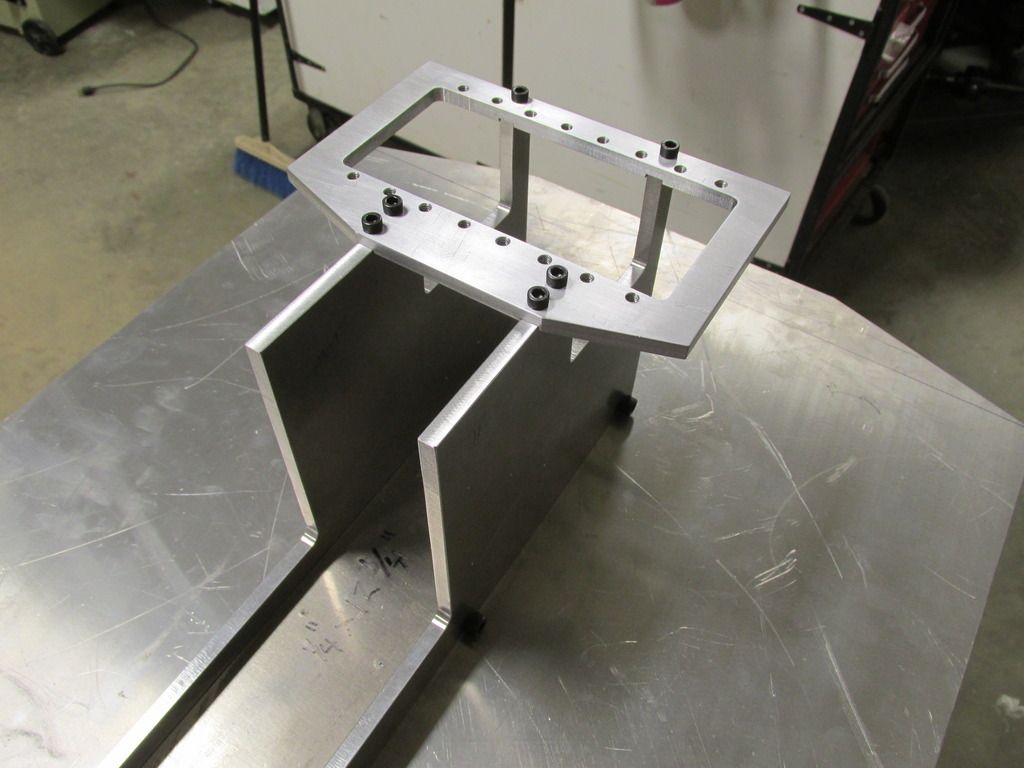

More work done on the frame....servo tray is finished and installed

[IMG]  [IMG]  [IMG]  The 1/4" shaft under the servo tray will be the pivot point of the spring loaded belt tensioner for the small vbelt pump drive. Throwing around the idea of adding a sevo to the tensioner shaft and being able to disengage the belt, the motor would continue to turn but the pump would stop, decreasing the amp draw and adding a little bit of battery time....really trying to avoid using an ESC on the pump motor if possible....just a thought [IMG]  [IMG]  [IMG]  Thanks for looking.... |

|

#154

|

||||

|

||||

|

I think if you're able to properly time your swing to your hydraulic speed, your cylinders will always be in motion lowering the amp draw from the pump, and an esc on the pump would help with that too varying pump rpm with the number of valves activated at any given time.

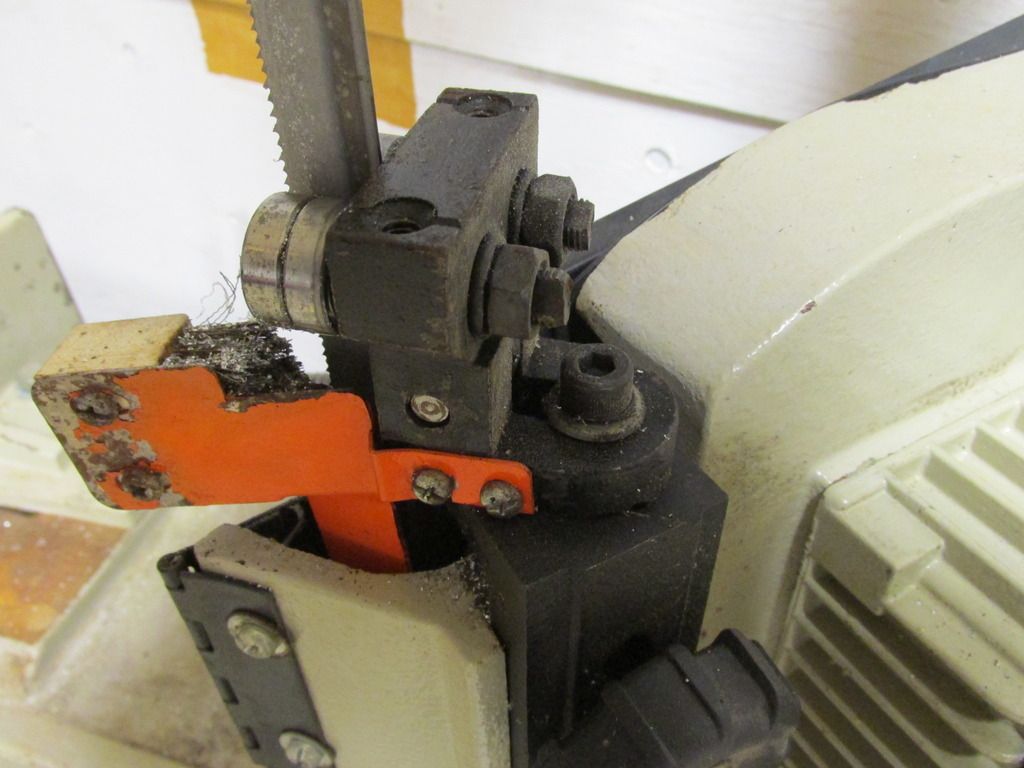

This is an interesting picture... you've turned a horizontal bandsaw into a vertical with cutting table, could I see more pics of how you jigged that up?

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#155

|

||||

|

||||

|

Joe, Some of the smaller metal cutting bandsaws come with tables to convert them from horizontal to vertical cutting. I have had mine for about 20 years and still going strong when you remember to change the blade

__________________

LYNN |

|

#156

|

||||

|

||||

|

I have never seen such an option before Lynn, thanx for the insight.

__________________

Sharing knowledge is one thing that defies basic arithmetic logic --- the more you share, the more you get! Joe |

|

#157

|

||||

|

||||

|

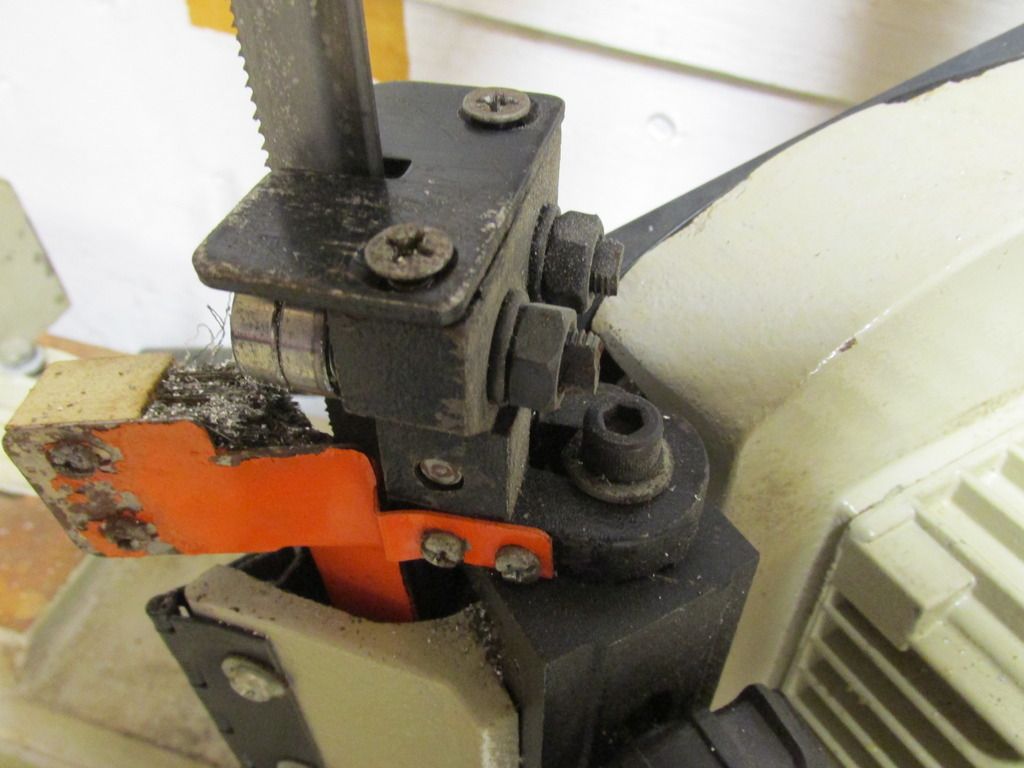

Joe.....Here are a few pics of the small "table" attached to the 7" x 12" band saw, it measures 9.5" x 10" and it came with the saw from new just as Lynn already mentioned, I had a 4"x6" bandsaw and it also had a small table for using as a vertical. Even though it is not very rigid and rather poorly mounted to only the blade guide it works surprisingly well (for small stuff), quick and easy to install and is very handy for cutting smaller parts....hope the pics are helpful

KP  [IMG]  [IMG]  [IMG]

|

|

#158

|

||||

|

||||

|

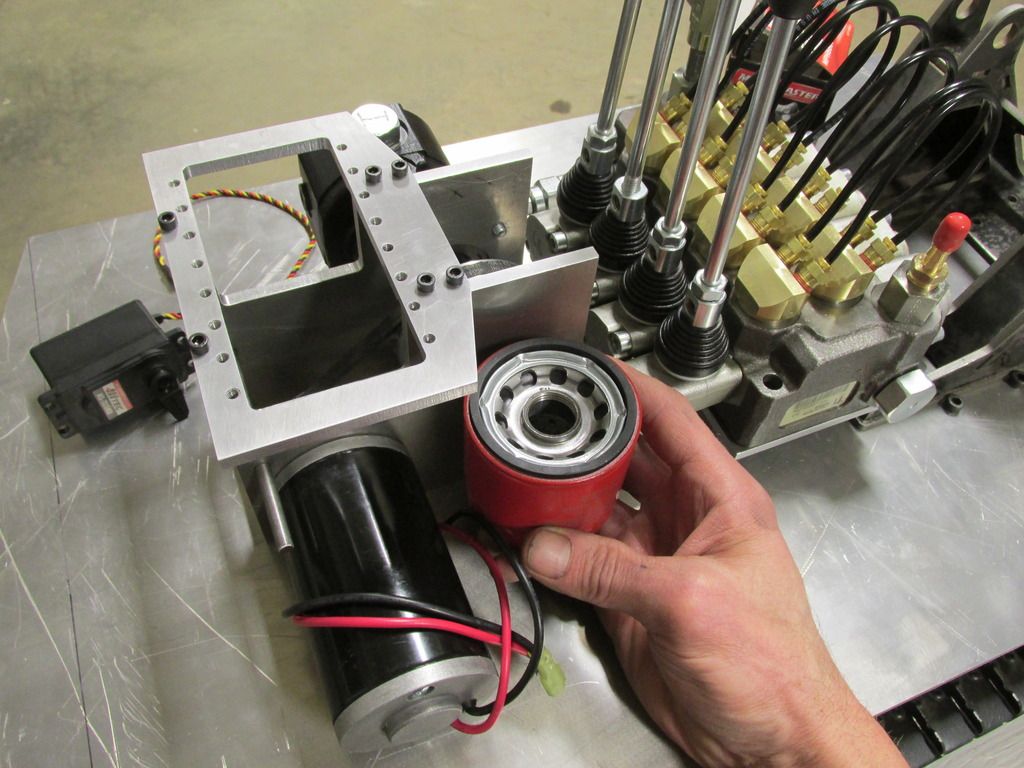

Got the motor and pump mounted....

[IMG]  [IMG]  [IMG]  I will need to make a remote filter mount for this oil filter...decided to go with a bigger filter because of the volume of oil being moved around, I don't think a small inline filter would handle the flow very well...slowly getting this all figured out...hope it all works...LOL [IMG]

|

|

#159

|

||||

|

||||

|

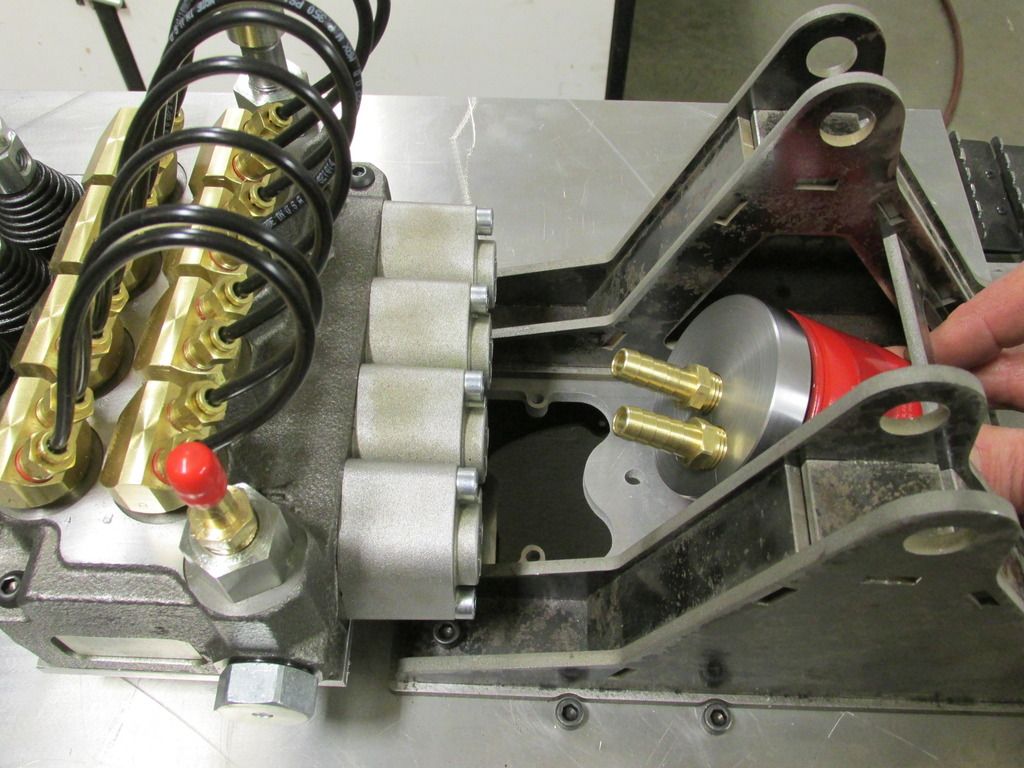

Got some time to build the remote oil filter mount, glad I had a chunk of 3.5" 1018 round bar because this is not how I was going to build it originally, had a change of plans.....found a good spot to hide the filter so needed to make it fit the new location, a good way to use the dead space...

[IMG]  [IMG]  [IMG]  [IMG]  [IMG]  Here is the new hiding spot.......just the right amount of space [IMG]  [IMG]  [IMG]

|

|

#160

|

|||

|

|||

|

This Machine and your skills are fascinating to watch

__________________

Steve |

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|