|

|

|||||||

| Construction Equipment If it digs, pushes, hauls dirt "off road" post it here. |

|

|

|

Thread Tools | Display Modes |

|

#21

|

|||

|

|||

|

Simply, wow !

|

|

#22

|

|||

|

|||

|

Real drum brakes even! Impressive!

|

|

#23

|

|||

|

|||

|

Thanks.

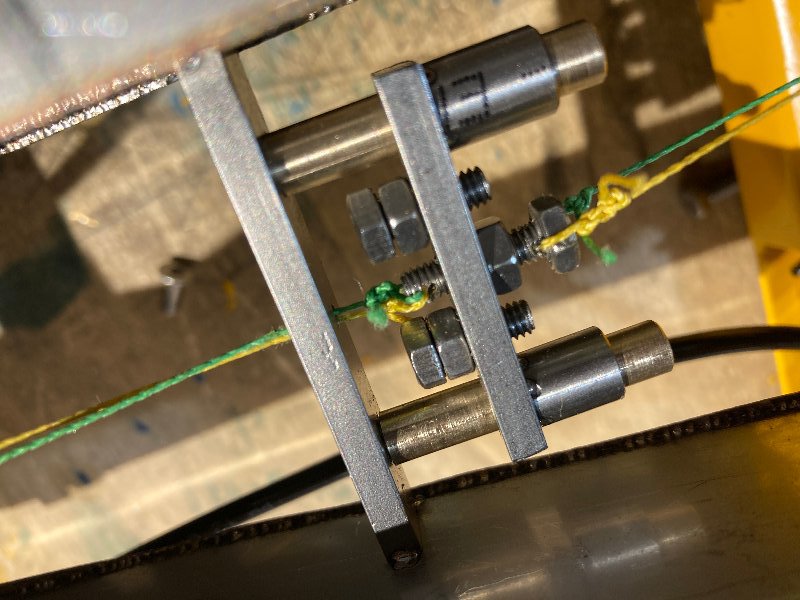

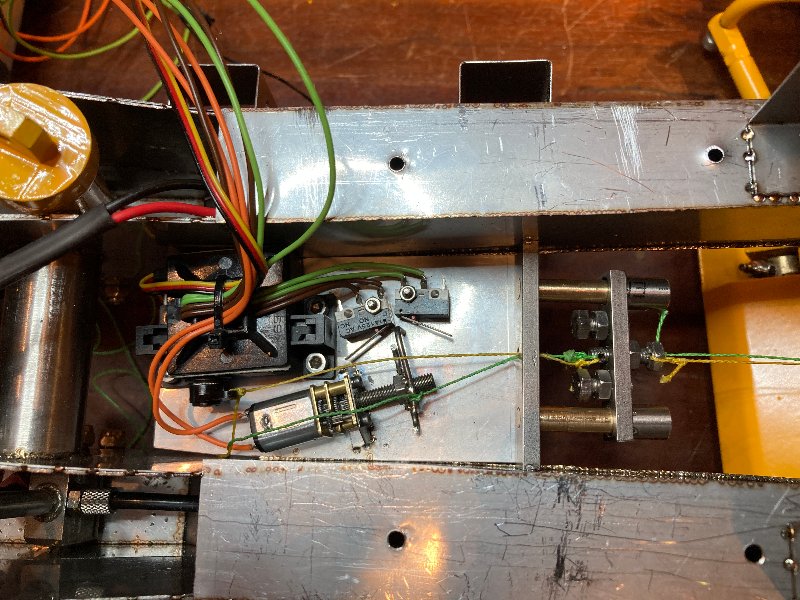

I need two different actuators for my breaks, like the big ones I need a driving and a parking brake. But i won't two bowden cables. Therefor i've made a central platfrom between the frame. Later truly invisible. A simple sledge to hold a constant direction. left to the actuators . right to the drums.  the testing arrangement was simple and ugly.  that must be prettier. to get a weldeable bowden tube in my tiny sizes was impossible. so I've bought a really small tube stainless

__________________

Regards Ralf |

|

#24

|

|||

|

|||

|

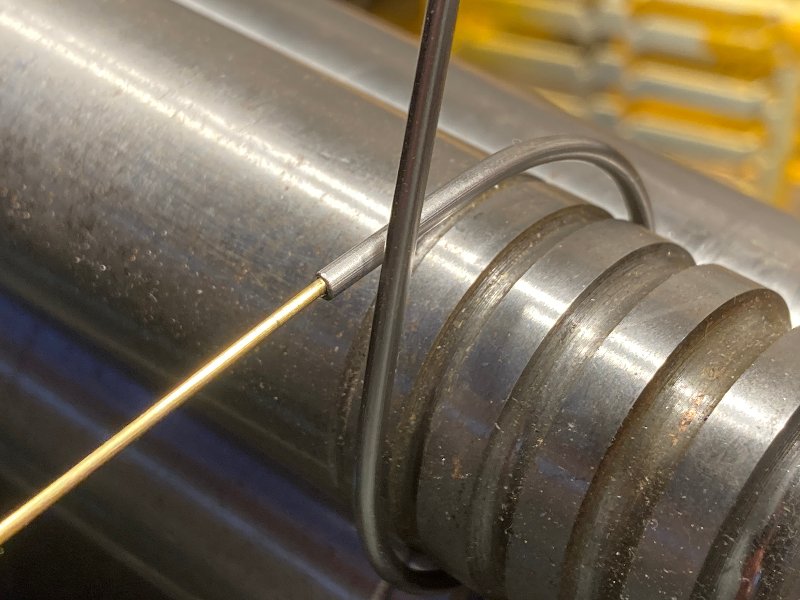

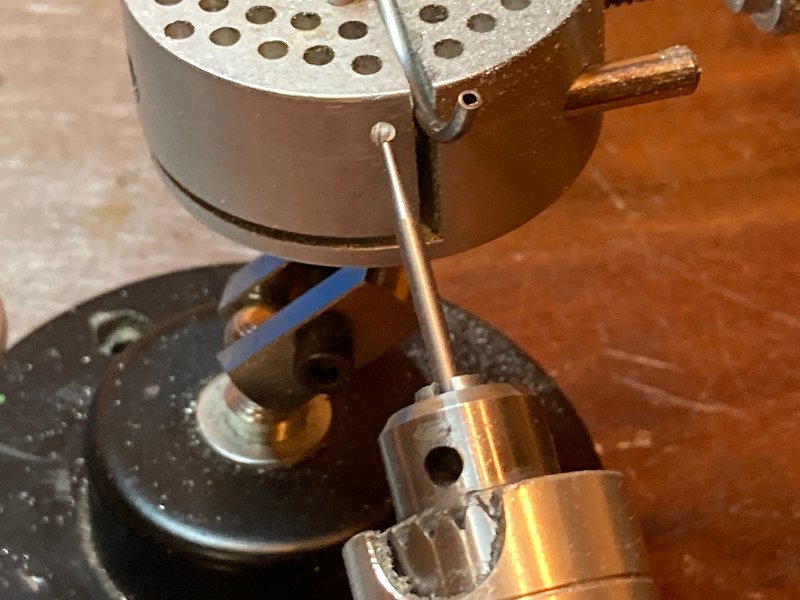

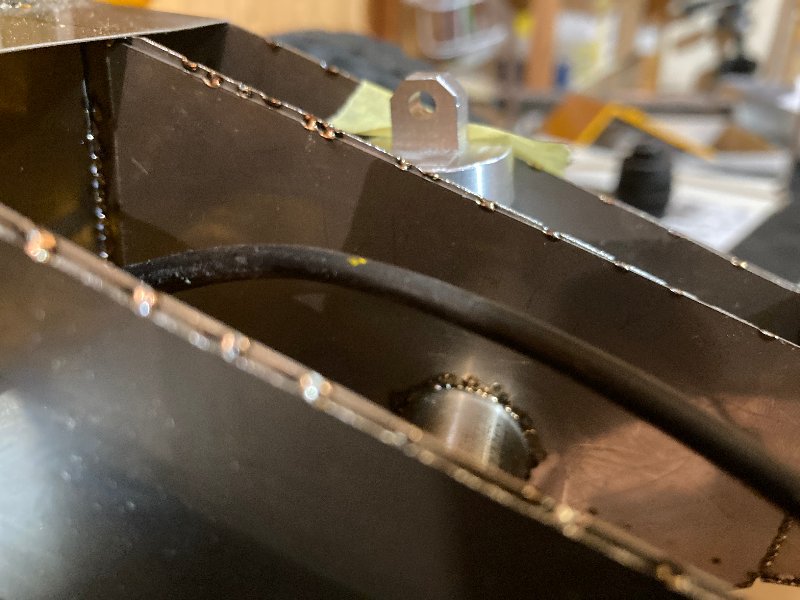

....

bending such a small tube  An inlay from 1mm brass rod was the solution Bending worked wonderful smooth  but i need not a ring but four 90° parts.   inner deburring with a small ball end mill  and welding on the screw wich hold the axle onto the c-hub to avoid length-changing while steering.  On the other side, a servo and a small n20 gear motor has taken their place. together with two end switches for the motor, they are the rest of the mechanics.  A short clip of their work, you can see here

__________________

Regards Ralf |

|

#25

|

|||

|

|||

|

Wow what a great scratch build !

Keep up the good work ! |

|

#26

|

|||

|

|||

|

Looks like you got a Optimum milling machine, is that BF20 ?

Did you cut all the sheet metal parts yourself ? And also, great work

__________________

Ari To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#27

|

|||

|

|||

|

thanks again.

Quote:

and yes. i buy simple sheets and cut them self. my tools are a simple lever shear, flex bandsaw, some bender and a old bosch belt sander. I'm a programmer by trade, so i could use a cad and buy laser cutted metal, but i won't work with computers after the whole day on it. ------------------ Last complicated parts are the telescopic lift cylinders.  They are located in the big slots inside the frame. Big? When you plan and estimate the sizes of the cylinder, the slots gets smaller and smaller  Seldom I've planned so long for a single part. Maximum and Minimum Angles, posibilities in machining, needed pressure to lift, sizes of the cylinder, rods and pistons and so. So much interdependent variables.  I think, the fifth or sixth plan was the base for the first try. I think, the fifth or sixth plan was the base for the first try. I'll show you the second and last attempt

__________________

Regards Ralf |

|

#28

|

|||

|

|||

|

Quote:

I also have a BF20L that I converted to cnc , and I love it.

__________________

Ari To view links or images in signatures your post count must be 10 or greater. You currently have 0 posts. |

|

#29

|

|||

|

|||

|

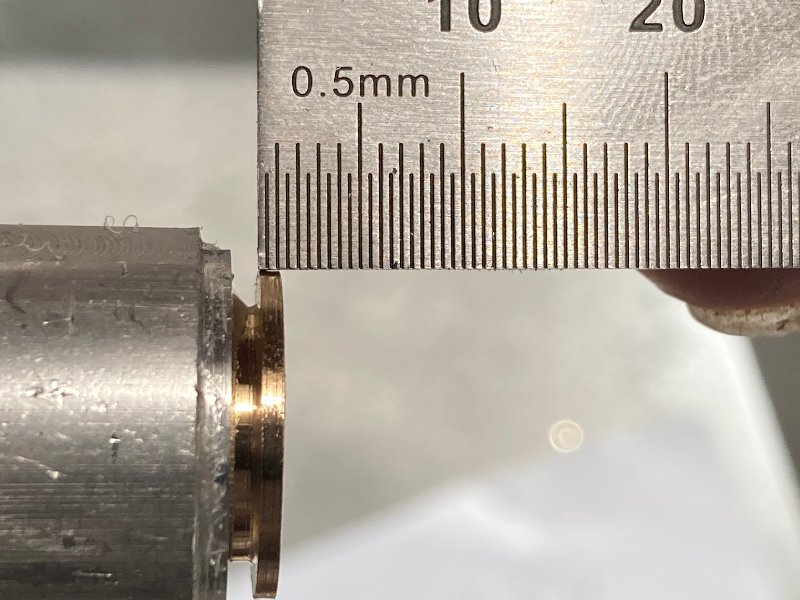

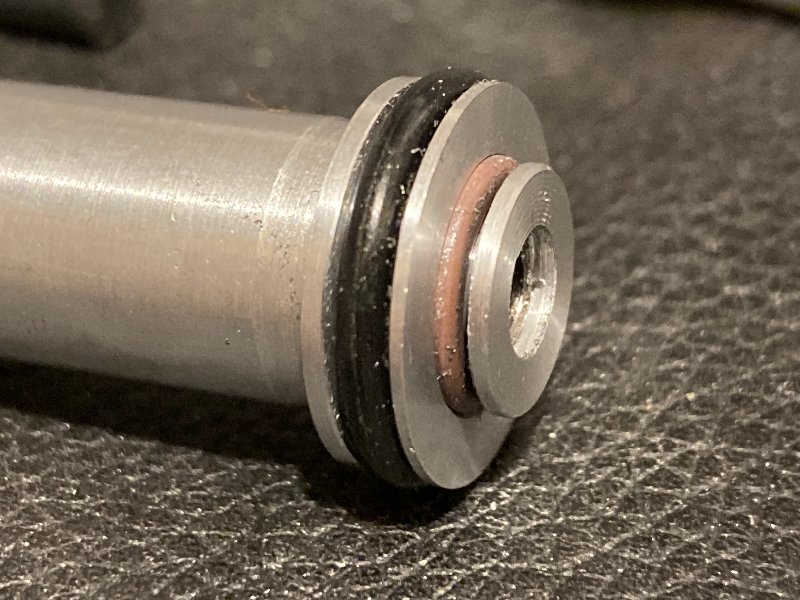

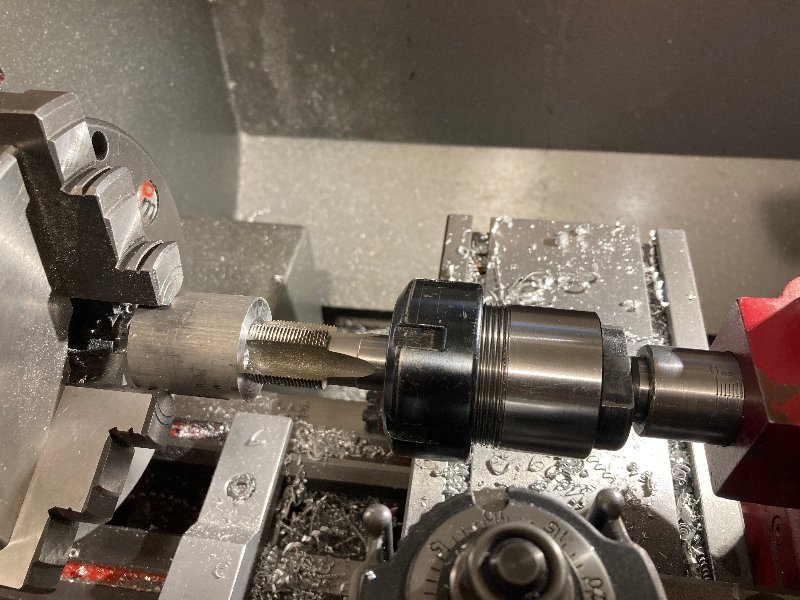

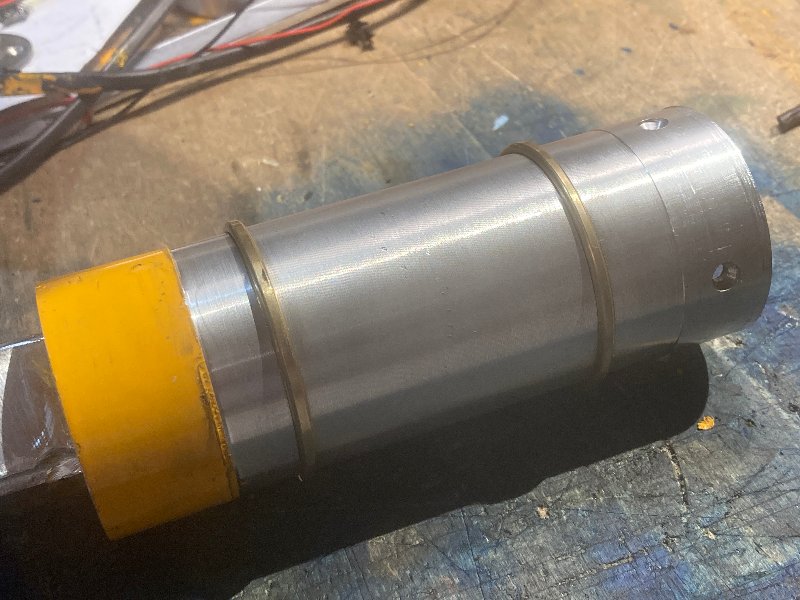

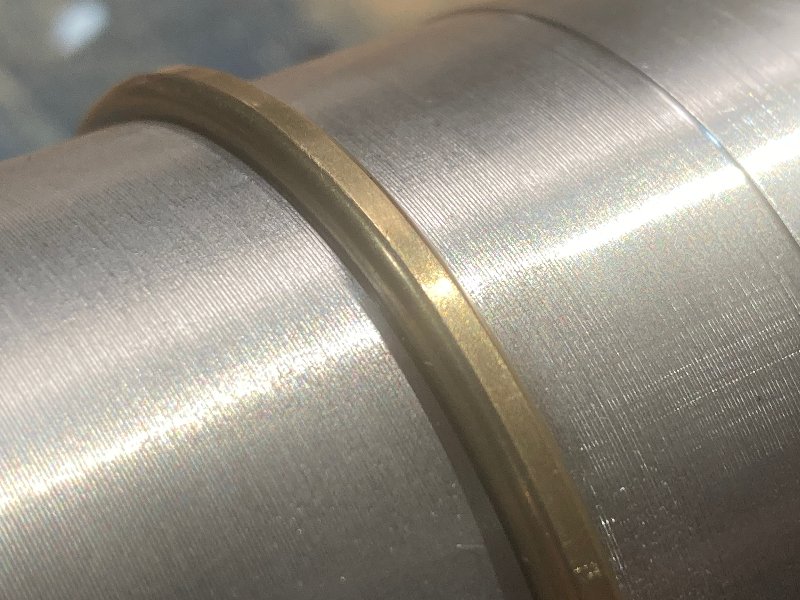

Well, after planning, the doing was a simple turning job

the guard rings are very small.  seals are simple o-rings   big thread on the lid    Fits perfect    To lock the trough in open state for working on the hydraulics are at the big ones simple Us wich will hook on the back plate. So do i  Works  Here you can see the last part of the cylinder with the flange. both from stainless to be able to weld. All other parts are from aluminium.  the original have a maximum tilt angle of 53°. almost   later, after some test and measuring, i'm able to raise the size of the guard-rings. that brings a lot more stability.

__________________

Regards Ralf Last edited by pufferfish; 01-24-2022 at 02:13 PM. |

|

#30

|

|||

|

|||

|

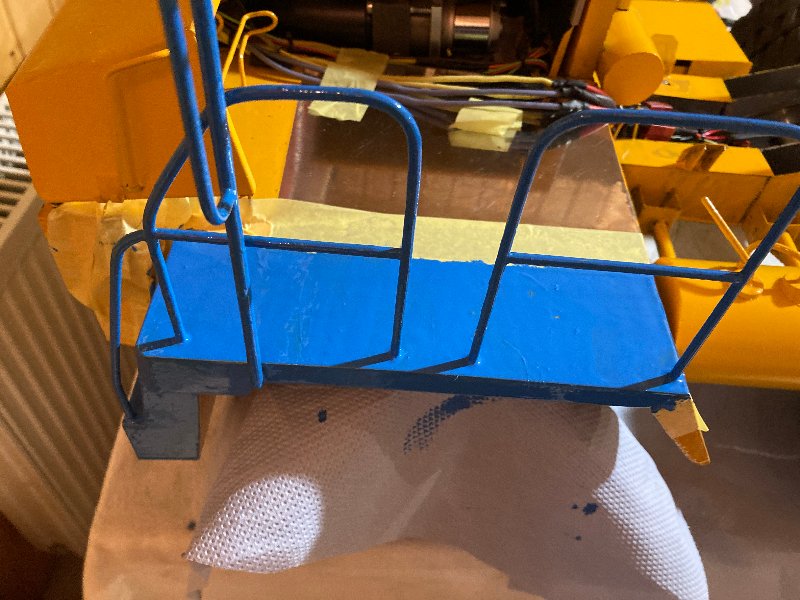

Last post so far

The exciting parts are done. Followed by things i have to do. Hydraulic arrangement  Many stainless sheets .3mm or .5 mm are cut, bend and welded to build the front.  The bonnet is parted.    on the back the massive airfilters  tank  battery tray  after all the yellow some belaz blue  and, tradional for me, the last thing: The cabin  Et voila. Almost completed   Actually the one and only clip with my Belaz 7540 Mining Dumper working. (Don't mind the unscale Loader  ) ) Here it is Now it's waiting for Spring to make a better clip and get some interieur into to the cabin. Thanks for your Interest. Maybe you'll watching my thread to build a more scale Loader

__________________

Regards Ralf |

|

#31

|

|||

|

|||

|

Yours looks better than the real thing. Fantastic build.

|

|

#32

|

|||

|

|||

|

Nicely done! I always enjoy the imagination and skill involved with scratch builds.

|

|

#33

|

||||

|

||||

|

Beautiful machining work on everything!

Even the latches for engine cowls are amazing

__________________

What do ya mean "Cars are neither Trucks or Construction"? It's still scale, and i play fairly well with others, most of the time... |

|

#34

|

|||

|

|||

|

Hi,

A usual method to move an excavator is to use a dumper and transport

__________________

Regards Ralf |

|

#35

|

|||

|

|||

|

Hi there,

some months later...... (during them i've built a 1/10 stainless steel land rover forward control) ....... the dumper needs an improvement of his drive train. fully loaded it was a bit weak. After a detail research i've found some issues. The rims are able to get contact with the axle and the motors don't get enough power to work properly. First attempt to seperate rims and axles are a gliding tape glued onto the axles. Unfortunately works is not good. Second attempt are these brass rings with the function of very small bearings.   After a couple of new escs i've found the working solution with seperate hobbywing 1080 for each motor. Now the dumper can work in soft and hilly terrain too.  traces in the sand (including a footstep in size 16)

__________________

Regards Ralf |

|

#36

|

||||

|

||||

|

That came out really awesome!

Your mining truck is a beast

__________________

What do ya mean "Cars are neither Trucks or Construction"? It's still scale, and i play fairly well with others, most of the time... |

|

#37

|

||||

|

||||

|

Impressive work, I really like the working drum brakes.

-Shawn- |

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|